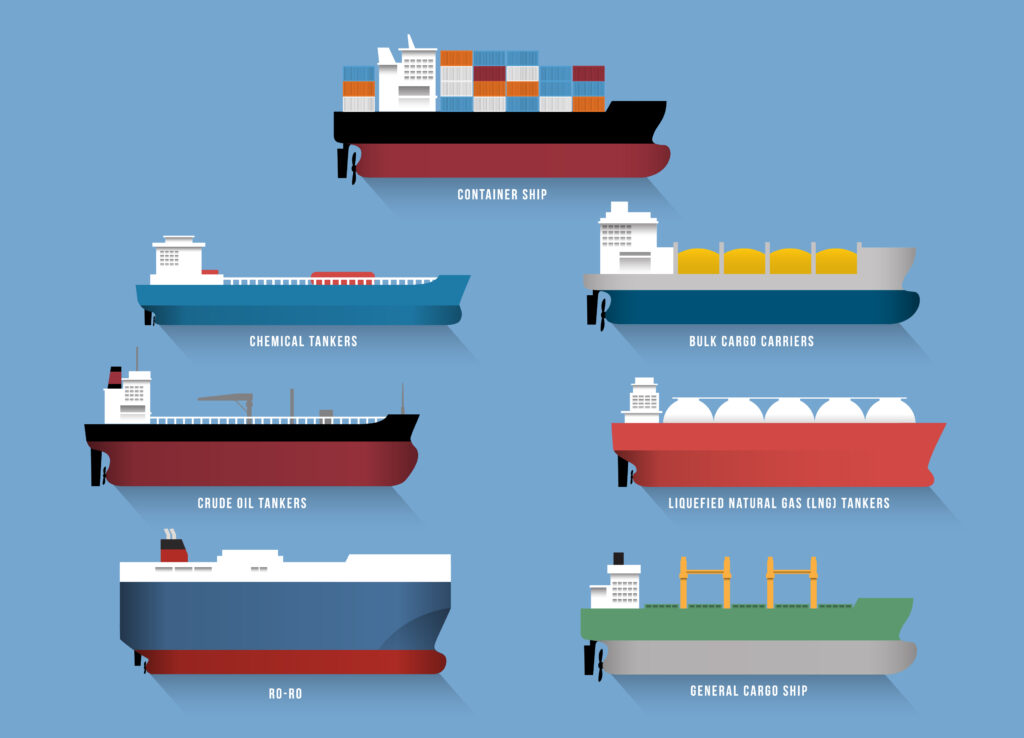

There is a wide range of different vessels. The international dry cargo and tanker markets are immense and are served by numerous ships of several types and of various sizes. Some of them follow standard designs and can carry a variety of cargoes while others are more specialized and able to carry commodities which the standard vessels cannot. According to the UNCTAD, in early 2019 the total world fleet stood at 95,402 ships accounting for 1.97 billion dead-weight tons (dwt) of capacity.

General Cargo Ships

Traditionally, general cargo vessels have been the backbone of the world’s merchant fleet, transporting cargo safely from one place to another. In fact, there are thousands of cargo ships on the move around the world, transporting goods across the globe and are crucial for international trade by transporting things such as food, petroleum, furniture, metals, clothes and machinery.

Cargo is usually in the form of pallets or bags and is known as breakbulk. There may be specialized handling facilities for such cargo, but usually loading and unloading is carried out using cranes and straps for boxes or slings for bags. They are usually built in small sizes of about 5,000 to about 25,000-ton deadweight (dwt).

Nowadays, such vessels are built with two decks and they are known as “tweendeckers”. In tweendeckers, each cargo hold can be split into two different sub-compartments between or beneath the main deck and the tweendeck.

Bulk Carriers

Moreover, bulk carriers mainly carry bulk cargoes such as iron ore and coal while it is not uncommon general cargoes, such as bagged cargoes and steels, to be loaded in bulk carriers of smaller size. These large vessels are divided into several separate holds covered by hatches and can be identifiable by the hatches raised above deck level which cover the large cargo holds. In port, cargo is loaded by conveyor and spouts or by crane and grab. Some bulk carriers are geared; meaning that usually a crane is located between each hatch to allow the loading and unloading of cargo at berths without the need for shore equipment.

These vessels are single-deckers and they are not able to load containers. Their hatches have very large openings and the holds are unrestricted and free of obstacles so that the vessel to be loaded and discharged quickly. Due to the bulk nature of the cargo they load, the holds of these vessels have been constructed to be “self-trimming” to allow the easy and rapid stowage and trimming of the bulk cargoes.

In particular, during unloading, cranes with grabs are usually used although specialized equipment may be occupied for certain cargoes. Cargo will usually be unloaded into hoppers and will then be transferred by conveyor to silos or open storage. Some smaller vessels can discharge directly into road vehicles.

In contrast to the general cargo vessels which can load several different cargoes, cargo in bulk carriers is usually homogenous. There are several different types of bulk carriers with the main distinction between each other being their size, i.e. Handysize, Supramax, Ultramax, Capezine, or their trading area, i.e. Panamax, Aframax, Suezmax.

Container ships

Container ships have become the main way of transporting manufactured goods around the world. Namely, a container has a standard size to simplify transportation and can be transferred between truck, train and ship relatively easily. In particular, containers can accommodate anything from food to electrical equipment to automobiles. Containers are also used to transport bagged and palletized goods, liquids and refrigerated cargo.

Container ships are made up of several holds, each equipped with “cell guides” which allow the containers to fit into place. Each container is then attached to the vessel and to each other in order to provide stability. Once the first layers of containers are loaded and the hatches are closed, extra layers are loaded on top.

Containers are usually loaded by specialized or general-purpose cranes with container lifting attachments, yet some small container vessels are geared to allow self-loading and discharging.

Standard containers are measured as TEUs (Twenty-foot Equivalent Units) and are generally 20 feet (1 TEU) or 40 feet (2 TEUs) long. All standard shipping containers are 8 feet wide and 8 feet 6 inches tall. They may also be longer, taller or shorter standard sizes, but these are not as common.

Container vessels are used predominantly on liner routes and are some of the biggest vessels afloat. Ultra Large Container Vessels (ULCVs) such as the Emma Maersk, the lead ship of the Maersk E-Class vessels, can carry approximately 15,000 TEU, depending on container weight. Large container vessels are restricted by their size to certain ports around the world and are also unable to transit certain areas due to draft or other restrictions.

Containerships operate in a much different manner than other dry vessels; they are usually chartered on period time charters from major liner companies who then offer fixed prices for each container to end clients.

7 facts about containerships

- A large container ship engine has about 1,000 times more power than a family car.

- The gantry cranes that load and unload container ships can be 430 feet tall and weigh up to 2,000 tons.

- Container ships are technologically advanced. A good example is the computer software that enables precise planning for the loading and unloading of containers and keeps the vessel balanced by increasing and decreasing ballast at the touch of a button.

- A recent study by Lloyd’s Register found that the fuel efficiency of container ships (4,500 TEU capacity) has improved 35% between 1985 and 2008.

- It is estimated that on average a container ship emits around 40 times less CO2 than a large freight aircraft and over three times less than a heavy truck.

- Container shipping is estimated to be two and a half times more energy efficient than rail and 7 times more so than road.

- Weekly safety and fire drill sessions take place for all crewmembers when the vessel is at sea to make sure that they are practiced for any real emergencies.

Source: World Shipping Council

Reefer Vessels

Refrigerated vessels, also known as reefers, are indeed very specialized ships. Such vessels usually consist of perishable goods such as fruit or meat and cargo is stowed in holds which are then sealed and temperature controlled. They have two or more decks and their holds are insulated to keep the temperature in the holds at the cold level required by each cargo. Such vessels can achieve very high speed in order to reduce time and their gears can operate fast enough so that the cargo is not exposed during the load and discharge operations.

Markedly, traditional reefer vessels have been largely replaced by reefer containers which may be carried on container vessels. Reefer containers only need a power source to function although they are usually loaded to allow the crew to inspect them during the voyage

Crude Oil Tankers

On the other hand, tankers are ships that primarily carry huge quantities of liquid and a wide range of liquid cargoes, such as oil, water, wine, crude oil, chemicals and petroleum products and lots of different chemicals that need transporting. They come in many different sizes but some of the larger vessels have the capacity to carry several hundred thousand tons. Tankers may look like bulk carriers, yet their deck is flat and covered by oil pipelines and vents.

Like in the case of the bulk carrier, economies of scale have driven up the size of tankers and today the largest examples have a carrying capacity or “deadweight” of over 400,000 tons.

In fact, the largest ships afloat are the Very Large Crude Carriers (VLCCs) and the Ultra Large Crude Carriers (ULCCs). Their size ranges from about 50,000 MT deadweight to more than 500,000 MT deadweight which is the size of modern ULCC. These ships are designed to load crude oil and transport it to refineries around the world where it can be processed into petroleum products. The largest crude carriers often load and unload at offshore buoys and terminals as are too large to enter most ports.

Whatsoever, when refined, crude oil separates into various oil products. Product Carriers which are generally smaller than crude carriers, transport these refined products from larger terminals to smaller ports around the world. Products carried can include the gasoline, kerosene, gasoil while the heaviest are the dirty products known as fuel oils or residual oils, petroleum, jet fuel, diesel, asphalt, lubricating oil and tar. Smaller tankers are also used to transport non-petroleum bulk liquids such as molasses and palm oil. Product tankers vary in size from general purpose tankers up to about 160,000 tons deadweight.

Chemical tankers

Chemical carriers usually have a deadweight of 5,000-40,000 tons and often have specialized cargo systems suited to the type of cargo carried. These systems can include heating or cooling apparatus and advanced cleaning systems in order to ensure whether the purity of a cargo is maintained when loaded into a tank that may have previously carried something different. Chemical tankers are mainly used either for the carriage of oils which are extremely hazardous (IMO I); the carriage of edible and vegetable oils or very clean oil products (IMO II / IMO III).

LNG and LPG Carriers

LNG and LPG Carriers are a highly specialized form of tankers that have started as converted oil tankers but then evolved into highly specialized purpose-built vessels. They are designed to either carry Liquefied Petroleum Gas (LPG) or Liquefied Natural Gas (LNG) under pressure; with LNG carriers usually being larger than those carrying LPG. In fact, the largest LNG carriers are the ‘Q-Flex’ vessels with a gas capacity of up to 266,000 cubic meters.

LNG is carried in insulated tanks in minus162 degrees Celsius at atmospheric pressure so as to maintain them in liquid condition. Also, cargo tanks are generally spherical for strength. The LPG Carriers are used to load mainly propane and butane while they are also used for the carriage of chemical gas and ammonia. There are two different types of LPG Carriers; the fully pressurized vessels which load and maintain the cargo in a high pressure of 10-12 bars and the refrigerated which cool the cargo at temperatures of up to minus 50 degrees Celsius.

Heavy-lift and Project Cargo Vessels

Moreover, heavy-lift or Project Cargo Vessels are mostly purpose-built vessels that specialize in the transport of extremely heavy or bulky objects such as other ships and large industrial components. Some heavy-lift vessels are equipped with high capacity cranes to load at ports without a heavy-lift capability. Other types are semi-submergible, which allows a cargo to be floated into position before the heavy-lift vessel de-ballasts to lift the cargo out of the water.

Common project cargoes are wind turbine blades and towers, quay cranes and industrial machinery. Some project cargo vessels have been adapted further to suit their role. For instance, ‘Jack up’ vessels can put down ‘legs’ to lift themselves out of the water. This is commonly used by vessels installing offshore wind farms where stability is required during the placing of the turbine towers.

RoRo and Passenger ships

Roll on-Roll off or Ro-Ro vessels can come in many forms including vehicle ferries and cargo ships carrying truck trailers, but the major type used for the transport of road vehicles is the car carrier. These slab-sided vessels feature multiple vehicle decks comprising parking lanes, linked by internal ramps with access to the shore provided by one or more loading ramp. Cargo capacity of such vessels is measured in Car Equivalent Units (CEU) and the largest car carriers afloat today have a capacity of over 6,000 CEU.

The two important measures indicating the size of Ro/Ro are the length of the marked parking lanes and the size of the entrance ramp. Once the cars are aboard, they are braced to the ship’s deck to keep them from moving around while the ship is at sea.

Ro/Ro vessels are suitable for cargo which can be driven on/off the ship such as cars, lorries and cargo on trailers. This ship type is quite popular to transport vehicles as it’s safer and much faster to just drive a car onto the ship instead of using a crane.

Most ferries and cruise ships are Ro-Ro ferries as they usually carry out short journeys for a mix of passengers, cars and commercial vehicles can easily drive straight on and off.

Adding to this, passenger ships are officially defined as ships that carry more than 12 passengers up to cruise and holiday ships that can accommodate more than 6,000 passengers. In fact, passenger ships can be the most specialized cargo of all; the needs and desires of passengers have driven the design of the modern ferries and cruise vessels.

Notably, the demand for cruise ships expanded rapidly during the 1980s, leading to a new generation of large and luxurious ‘floating hotels’, lavishly equipped with lounges, fitness centers, casinos, restaurants, shops, entertainment facilities and pools among others, particularly when the ferry is on a relatively long route. The largest cruise vessels can be up to 360 meters long and 60 meters wide.

Additionally, high speed crafts, sometimes called ‘fast ferries,’ are mainly designed for civilian use as passenger ferries. They also include hovercrafts, catamarans and hydrofoil boats. High speed crafts can go faster than other vessel types because they use air pressure and powerful turbine propellers.

Livestock Carriers

Livestock carriers are those used to carry animals and there are two main types of such vessels; the sheep carriers and the cattle carriers. These ships are often converted from other types of vessels and are equipped with pens for large numbers of animals. The main considerations during the transport of livestock are adequate ventilation; food and water; but also, the capability of the reception facilities at the destination port to handle the cargo. Some livestock carriers are reported to be able to transport up to 120,000 sheep. A Common route for livestock carriers is Australia and New Zealand to the Middle East.

Tugboats

Tugs are also used to tow barges from port to port. These sea-going tugs are also employed for the movement of large structures such as offshore platforms and floating storage units. Some tugs are utilized to push barges; this is particularly common on rivers where the tug can exert more turning force on the tow.

There are also tugs that are designed to ‘slot’ into a barge or hull; once secured, this composite unit behaves and is treated like a standard powered vessel. These composite units, like tugs employed to push the cargo, are mostly common on North American river and coastal trade.

Modern tugs are highly maneuverable with pulling power, or bollard pull, sometimes in excess of 100 tons, although harbor tugs are generally much less powerful. Such vessels can be found in ports around the world in order to assist in the berthing, unberthing and movement of large or less maneuverable vessels within port limits. Tugs are also used to assist the most maneuverable vessels during periods of bad weather or when carrying dangerous or polluting cargoes.

Harbor tugs are also often employed to move barges, floating cranes and personnel around ports. Larger units are kept on standby in strategic locations to act as deep-sea rescue and salvage tugs. Even with the advent of highly maneuverable vessels equipped with thrusters and azimuth pods, tugs are enormously important to the industry.

Short sea vessels

In short sea and coastal trades, small versions of deep-sea general cargo vessels or mini bulkers are sometimes utilized. However, the short sea vessels, which usually have a deadweight of between 500 tons and 10,000 tons are constructed with special modifications for their trade. They are usually constructed with one hold served by an “open hatch” while holds are fully box-shaped to enable the loading of palletized cargo and increase cargo intake.

Modern box shaped short sea vessels used in grain trades are equipped with at least two moveable bulkheads enabling the vessel to load a full compartment comprising most of the ship’s capacity and a small compartment where the balance cargo can be slack without the need for bagging and strapping. Furthermore, recent short sea vessel designs also allow the superstructure and masts to be hydraulically lowered to enable the ship to sail beneath bridges and other overhead obstructions.

Last but not least, fishing vessels are boats and ships designed to catch fish and marine wildlife. They can be used both for leisure purposes and commercial fishing. There are millions of fishing vessels being used to catch fish around the world.

Some other specialist ships include anchor handling and supply vessels for the offshore oil industry; salvage tugs; ice breakers and research vessels.

DO YOU KNOW?: Read in this series