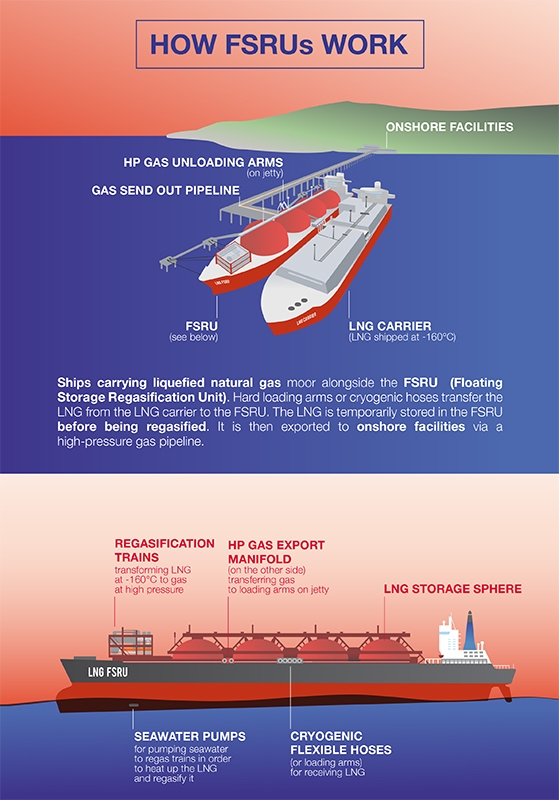

Floating Storage Regasification Units (FSRUs) are floating structures that bring LNG to the coast after receiving it offshore and regasifying it there. They provide the benefits of a quicker development process and reduced construction costs as compared to onshore storage tanks and regasification facilities.

FSRUs are built on LNG tankers and use similar technology to onshore terminals. One main difference is that the equipment has been modified so that it can be used in shipyards and on the sea. They can be installed as a separate unit aboard the LNG carrier, or they can be converted into an independent unit and placed in a specific location as an offshore installation.

For a newly built vessel, the equipment is typically integrated into the vessel and built alongside it. The equipment for a conversion is typically built as a separate module and retrofitted onto the tanker in a shipyard.

Hulls and storage

An FSRU’s hull and storage are identical to those of a standard LNG tanker. The vessels are built with a double steel hull for strength and either membrane or spherical (Moss) tanks.

LNG transfer

LNG is typically transferred from the supply tanker using the FSRU’s arms, but cryogenic hoses are also used.

Heating medium

The LNG is vaporized in heat exchangers that use either an open loop or a closed loop system.

- Open loop system: The sea water passes through once and returns to the sea.

- Closed loop system: A circulating heating medium, usually a fresh water/glycol mixture, is heated by steam from the ship’s boilers.

Boil-Off-Gas (BOG)

BOG generated from the LNG in the tanks is typically 0.10-0.15% by weight per day (ca 3-5 t/h) depending on the age of the vessel.

However, during the LNG loading operation excess BOG is generated in the FSRU piping in just the same way as when filling onshore tanks. Whilst some of the gas is returned to the supply tanker to fill the space previously occupied by the LNG, the excess gas needs to be managed.

The BOG is contacted with the LNG from the LP pumps and condenses back into LNG before entering the HP pumps and the vaporisers. At onshore terminals, gas sent out from the FSRU must be coordinated with ship loading operations in order for the recondenser to function.

Gas Export Arms or Hoses for FSRUs

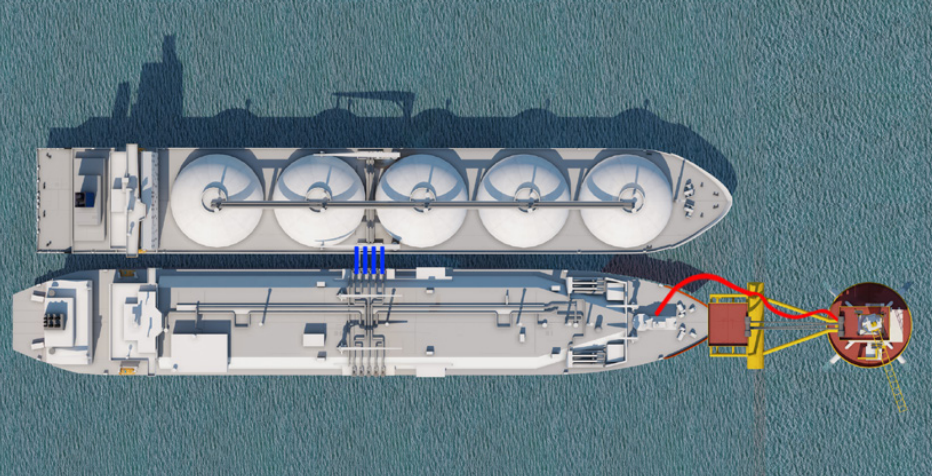

Gas is exported via a high-pressure gas export arms, but hoses can also be used. For offshore (open water) locations the gas is exported via a submerged turret loading system or an articulated arm which also provides the vessel mooring system. Not all FSRUs are fitted with submerged turrets.

Watch this video below by MOL which illustrates how an FSRU operates.

Configurations

As ExxonMobile explains, FSRUs are usually self-propelled Moss-type, conventional, or large LNG ships outfitted with regasification systems and auxiliary equipment. Some FSRUs are not self-propelled and have storage and regasification systems that are tailored to the customer’s needs.

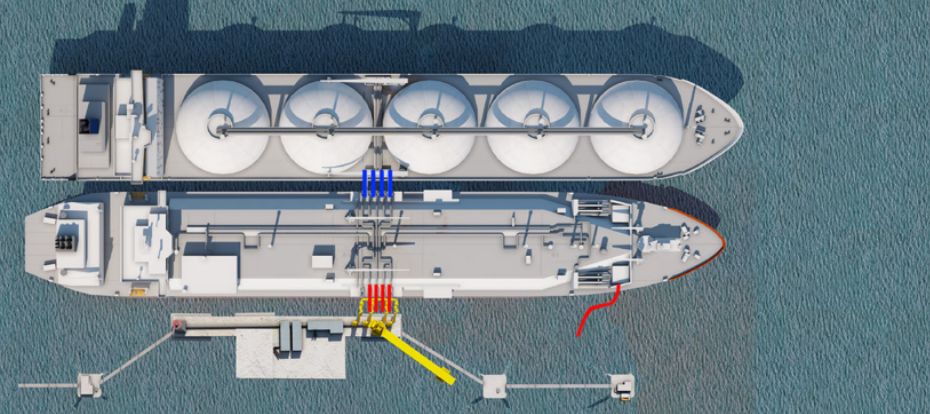

- Single berth FSRUs

LNG ships can moor alongside the FSRU and offload LNG for regasification and then supply directly into a pipeline. This low-cost option works best in protected harbors or near-shore with water depths of 15-30m and mild weather conditions.

- Singe Point Mooring FSRUs

There are numerous mooring options, depending on the site and conditions. Most have been tried and tested in the offshore oil industry. Some specific solutions include mooring towers, yokes, and turrets (internal or external to the FSRU).

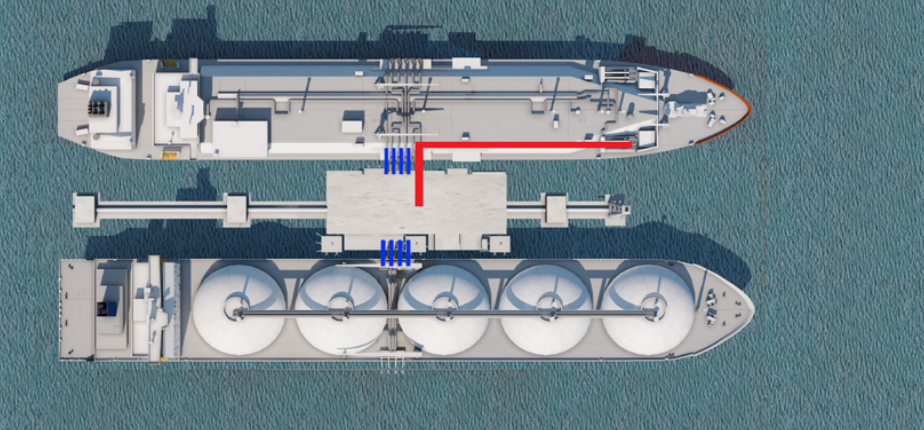

- Cross-dock FSRUs

Segregated berths for LNG ships and FSRUs provide flexibility and improved availability. Spacious sea island concepts can be created to enable a flexible, offshore operation: this allows for adding more vaporizer capacity and further berths for a Floating Storage Unit (FSU) or another FSRU.

Environmental impacts

In a 2017 report, AGL identified the following as the main environmental consequences of an FSRU:

- Noise: Because the FSRU is an industrial facility, some noise will be produced. When the ship is in motion, the engine room vent fans make the majority of the audible noise. While heat exchangers are in use, additional noise is produced by the passage of water through them.

- Cool water discharge: The use of sea water to heat LNG results in seawater being returned to the sea that is initially 6-7 degrees cooler than the ambient temperature. The water usually returns to ambient temperature within the mixing zone well within the berthing pocket occupied by the FSRU.

- Plant defouling processes: The intake of seawater into any pipe or plant system will lead to biofouling of the system. To combat this hypochlorite is typically used to disinfect pipes and plant systems.

Did you know?

Hypochlorite is produced by running an electric current through seawater, a process known as electrochlorination. This process can produce residual chloride content in this water, which quickly decays upon return to the mixing zone.

Ammonia FSRUs

As ammonia is rising in popularity as an alternative marine fuel, companies have started efforts to create ammonia FSRUs. For example, in early 2022, MOL announced the completion of a concept study on a floating storage and regasification unit (FSRU) for ammonia fuel, in collaboration with Mitsubishi Shipbuilding.

In another instance, in late 2022 Hyundai Heavy Industries Group announced that is developing a floating storage re-gasification unit (FSRU) for ammonia in cooperation with Korea National Oil Corp. (KNOC) and Lloyd’s Register.