Since steel-ships were introduced to shipping, water has been used as ballast to stabilize vessels at sea. However, ballast water can contain organisms, which when transferred, are able to establish a reproductive population, thus becoming invasive. For this reason, IMO has established the “International Convention for the Control and Management of Ship’s Ballast Water and Sediments”, mandating the implementation of ballast water management plan and ballast water treatment system on board ships.

The BWM Convention entered into force on 8 September 2017. The adoption of all the necessary Guidelines for the universal implementation of the BWM Convention and the approval and certification of modern ballast water treatment technologies have removed obstacles to the ratification of the instrument, and several additional countries have indicated their intention to accede to this Convention in the near future.

The Convention mandates all vessels to implement a ballast water management plan. Namely, all ships have to carry a ballast water record book, while they also must conduct ballast water management procedures to a certain standard.

Key issues during BWMS installation

Ballast Water Management Systems may be a compliance method related with environmental regulations, but when it comes for installation onboard the vessels, there are safety aspects that need to be considered.

As Mr. Stamatis Fradelos, Director, Business Development, ABS, highlighted, when selecting a BWMS, owners must carefully consider the risks associated with:

- Location aboard the vessel;

- Chosen technology;

- Vessel’s type.

In addition, the right installation as well as commissioning is another crucial factor for installing BWMS. In fact, according to Jad Mouawad, CEO at Mouawad Consulting, around 50% of the issues faced with malfunctioning BWMS, could have been prevented by proper installation followed by commissioning.

We have on many occasions discussed the importance of proper commissioning of a BWMS. That is, actually checking that the BWMS works together with the ballast system of the ship and the way the ship is intending to trade, rather than just punching a checklist that shows the HMI of the BWMS working

However, despite taking measures to ensure the most efficient BWMS installation, problems might still occur.

A common situation is that an installed BWMS has not been used for a number of years. This means that there was not the proper maintenance, and as such the equipment became inoperable.

In such case, repairing the system could be difficult, and some owners took the decision to replace the BWMS with a new one.

Training vital for an efficient BWMS

These facts are making one thing clear. Training is crucial to properly operate a BWMS.

What training does, is explain to the crew how ballast water management is performed on board.

This means that the crew should be eventually able to know how to deballast, when to bypass the BWMS, how to react in case of difficult water conditions, etc.

[smlsubform prepend=”GET THE SAFETY4SEA IN YOUR INBOX!” showname=false emailtxt=”” emailholder=”Enter your email address” showsubmit=true submittxt=”Submit” jsthanks=false thankyou=”Thank you for subscribing to our mailing list”]

In addition, it explains to the Chief Engineer the whole process of the installation, so as to be able to perform the proper maintenance, know if and what components are not working correctly, and deal with discrepancies in sensors.

Of course, all these aspects of training should be accompanied by an introduction to the BWM regulation. When carrying out this training, the crew must perform a thorough review of the Ballast Water Management Plan, which is the most important document that must be consulted regarding an efficient operation of the ballast system.

In order to facilitate the training on BWM, ABS has published a guide providing specific recommendations. These include among others, the following:

Competency Assessment

Carrying out computer-based standardized testing at the end of the BWMS training sessions could provide evidence and records for management to prove the competency levels of the crew.

Technology Transferability

- Operations should be videotaped, along with maintenance and troubleshooting processes for the BWMS in real-time operations. These should be available for training;

- Take pictures of the sequences how to operate the BWMS. Combine the photos as a training tool, in order for the trainee to use them and visualize the text-based instructions;

- Use physical tagging methods, referencing the procedures to help less experienced crew get to know the operating sequences;

- The more experienced crew should write ship-specific operating instructions.

Shore-based Management

- Owners should include shore-based management (ship managers and port engineers) in the BWMS training programs as well as the vessel’s crew;

- Shore based management could provide regular updates on the latest BWM regulatory requirements (international, national and local requirements) and send it to the vessel for awareness;

- Messages/letters/email/checklist that detail local BWM requirements of the next port-of-call could be sent in advance to the vessel or port agent to prepare them for additional requirements to provide updated awareness;

- Chief Engineers/Master/Superintendent/Technical managers should also be knowledgeable and competent with the ship-specific BWMS operation to better assist the crew, particularly where there may be several different treatment technologies employed across their fleet.

Training Facilities

- BWMS manufacturers should provide practical BWMS training;

- BWMS training programs could also be include into maritime academies;

- Simulators could be proven beneficial, as they mimic real BWMS operations to train the students.

Of course, IMO has also provided training requirement. For example, Guidelines G4 establish that a ship’s Ballast Water Management Plan:

Should include training and education on ballast water management practices and the systems and procedures used on board the ship

Some of these guidelines are about maintaining the Ballast Water Record Book, while others regard more specific aspects. Specifically, they require training on operating and maintaining installed ballast water treatment systems, as well as on safety aspects related to the particular systems and procedures on board.

What is more, USCG has also set out training goals. As Rear Adam Paul Thomas, USCG’s assistant commandant for prevention policy, explains, operators must review and update ballast water management plans, in order to contain crew training requirements, covering “proper procedures and use of any ballast water management equipment.”

Moreover, there are certain questions that could lead to a better training method. These are:

- Are the crewmembers in charge of operation sufficiently trained and able to perform their duty safely?

- Is there any evidence of onboard training and familiarization? Is BWM training a requirement?

- Are the limitations of the system and safety requirement known?

- Have crewmembers operating the system demonstrated their ability to record the BWM operation?

- Are the crew members able to identify air vents and sounding pipes?

- Is the tank entry procedure available? Is there evidence of the use of the procedure?

- Is the crew aware of the precautions to take when handling sediments?

Speaking on BWMS training, Paul Jinhwa Kim, Manager, Panasia Europe BV, has identified four major types of training methods:

1. On-Site Training: This is a basic step of training carried out during commissioning aboard. Since commissioning is main role of this step, it is not easy to acquire enough time for training. In general, minimum 4 hour training is recommended for operators to have a real operation experience by themselves and get feedbacks from maker.

2. Training at HQ: For all makers, HQ (Head Quarter) is the place with everything available including real equipment, technicians and facilities. Therefore, it is easy for makers to provide a detailed education to the vessel owners or operators at their HQ. However, the vessel owners or operators should bear the cost of accommodation with students’ labor fee.

3. Training Center: Training Center is a regional educational complex where the vessel owners or operators can access for training with minimum expenses. Training Center is in general composed of educator, real equipment and educational materials. At the center, followings at least shall be dealt with.

- Theoretical Part includes: Component explanation; BWTS operation; Installation & Commissioning; Trouble Shooting (alarm & trip condition); Maintenance & Calibration; BWTS System settings;

- Practical Part includes: Practice on BWTS operation through computer based simulation; Practice on overhaul on each component; Practice on hands-on maintenance & calibration; Practice on trouble shootings (alarm & trip condition).

4. CBT (Computer Based Training) Software: CBT is in general window based training software in a form of CD or USB with which operators can have repetitive lectures regarding BWTS. This is developed for owner to prevent knowledge leakage through frequent crews change-over.

SAFETY4SEA has examined this issue, and in order to feel the pulse of the industry, it asked the following question: Should BWM training be a mandatory requirement?

With a staggering 75%, the vast majority believes that training should be mandatory, with 25% believing otherwise.

BWM Convention now applies for existing vessels

The IMO Ballast Water Management (BWM) Convention entered into force in 2017, but now a new milestone is upon us. Namely, from 8 September 2019, the Convention applies to existing vessels.

From 8 September 2019, existing vessels have up until its next IOPP Certificate renewal survey to comply. This means that ships with a keel laid before 8 September 2017, are possible to need to install an approved ballast water treatment system (BWTS) at some point between 8 September 2019 and 8 September 2024, according to the date of IOPP certificate renewal.

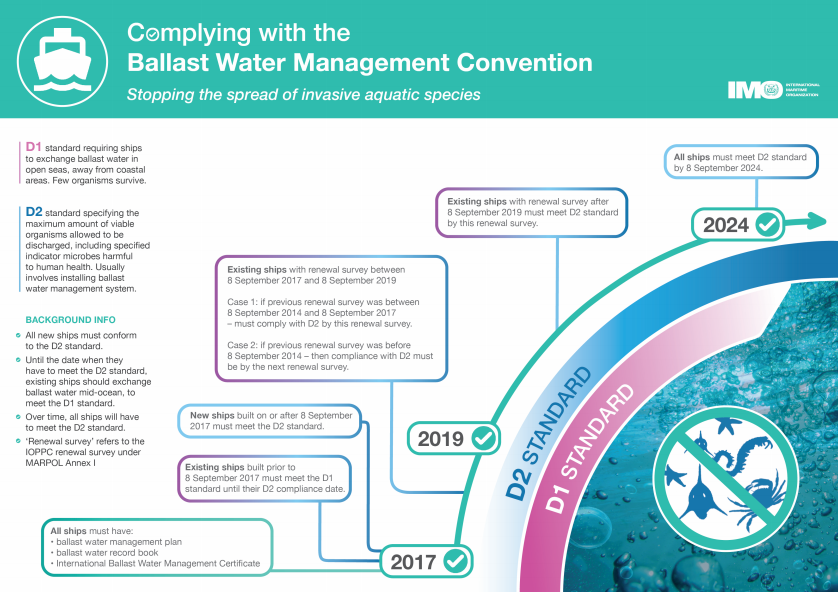

What is more, IMO has published a detailed infographic, in which it describes step-by-step the procedure for ships to comply with the BWM Convention.

Ballast is an essential component for safe shipping. However, it comes with certain serious issues that can significantly affect the marine environment. A BWMS comes to provide a solution to these problems, but the crew must be properly trained, in order to operate the system correctly.