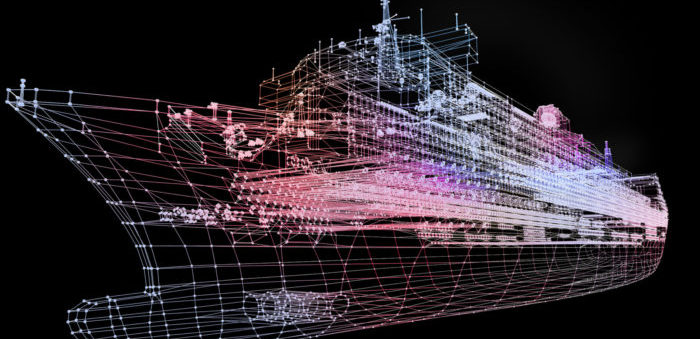

MAN Energy Solutions introduced its new digital platform. MAN CEON collects and evaluates operating and sensor data, and enables the real-time monitoring of marine or power-plant engines, turbines and compressors. It also integrates data and information from MAN machinery and its operational environment, and uses intelligent analysis tools for evaluation and forecasting.

Originally developed in 2016 to boost the company’s focus on delivering a new generation of digital services, MAN Energy Solutions’ digital team is behind the development of MAN CEON.

[smlsubform prepend=”GET THE SAFETY4SEA IN YOUR INBOX!” showname=false emailtxt=”” emailholder=”Enter your email address” showsubmit=true submittxt=”Submit” jsthanks=false thankyou=”Thank you for subscribing to our mailing list”]

After connecting their installation to MAN CEON customers have access to the platform through a web application on their PC, or by using a mobile. Then, data is sent and processed continuously, while encrypted data transmission and a multi-level authorization procedure during login aims to ensure maximum data security.

The operating data of all systems and ships networked via CEON can be transmitted to MAN service centers in real time. After that, MAN experts support customers with problem solving and maintenance. This is facilitated by the communication functions within MAN CEON, which enable video and audio live-chats.

MAN CEON is considered the new backbone of the company’s developing digital-service business, according to Per Hansson, Head of Digital and Strategy at MAN Energy Solutions.

All of our machines, whether engines or turbomachinery, are equipped with hundreds of sensors that transmit data constantly. MAN CEON enables the efficient collection, storage and evaluation of these data volumes

In addition, the platform is scalable as it is designed to monitor several thousands of customer installations with its data-processing capacity. Moreover, MAN is monitoring down to the level of small subcomponents, similar to a ‘digital twin’, with high-resolution data available on demand. Cloud-based technology and algorithms that automatically identify and report problems help this process.

With MAN CEON, we can provide our customers with even better support during their daily work and optimize the availability and efficiency of installations, regardless of whether it is a ship on the high seas, a power plant, an industrial application, or even an oil platform. We can instantly respond to unusual operating-data and quickly offer customized solutions and services

Mr. Hansson concluded.