The World Shipping Council (WSC) is taking additional action to strengthen cargo safety standards and protect the lives of the people working in the supply chain, the environment, and the integrity of the global supply network.

As WSC explains, despite industry and government efforts, dangerous cargo that has not been declared, or that has been incorrectly declared or labelled, continues to cause fires and explosions, hurting and killing vessel crew and transportation staff.

As a result, building on screening processes and policies already in use by member carriers, the WSC is developing a shared industry process for cargo screening and inspections.

A common industry approach to cargo safety will create a safer working environment not only for ship crews, but for everyone involved in inland transport or working in ports and terminals, as well as for the communities around us.

… said John Butler, President & CEO of the WSC.

The Cargo Safety Program will rely on a digital solution provided and operated by an independent third-party vendor. The solution will be made up of:

- a Common Screening Tool

- a Verified Shipper Database

- a Database of Approved Container Inspection Companies

The core functionality of the system will be to screen booking information against a comprehensive keyword library and risk algorithm. High-risk bookings will be flagged for further investigation and/or inspection, and lessons learned through experience will be used to continuously improve the screening tool.

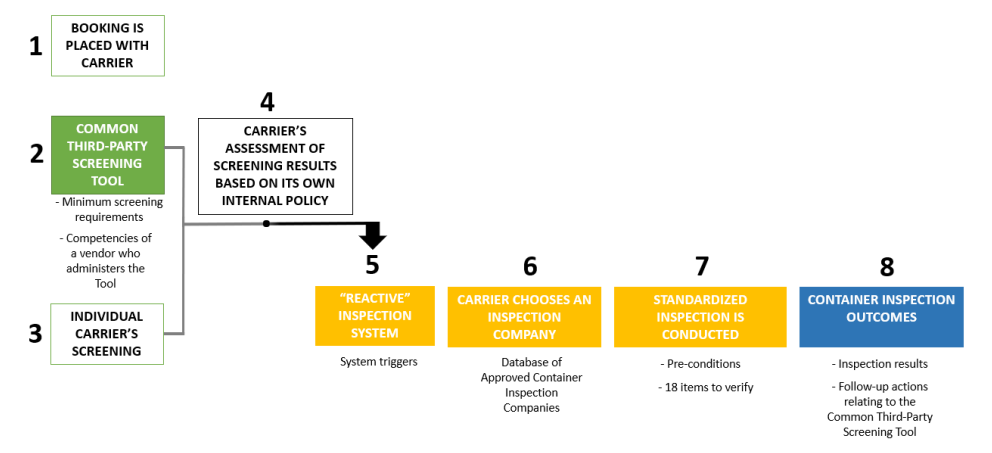

The emphasis is on identifying and correcting dangerous conditions before containers with dangerous cargoes are introduced into the supply chain. WSC also presented the 8 specific steps of this new process, which are as follows:

Step #1

The first step is cargo booking and is administered individually by each carrier with their respective customers.

Step #2

The second step is the use of the Common Third-Party Screening Tool. This is a key component of the new process as it introduces minimum screening requirements which are implemented through three forms of screening with several functionalities including a Shared Keywords Library, booking document authenticity verification, Know-Your-Counterparty, unusual behavior checks and a Verified Shipper Database (providing for minimum safety criteria for inclusion in, suspension from and re-instatement in the database). A service provider (‘Vendor’) that will be selected by the SSC will be required to establish and administer the Common Third-Party Screening Tool.

Step #3

The third step is individual carrier’s screening and is administered individually by each carrier. This runs simultaneously with the Common Third-Party Screening Tool and is independent of the Common Third-Party Screening Tool.

Step #4

The fourth step is carrier’s internal assessment of the screening results coming out of the Common Third-Party Screening Tool as well as of the individual carrier’s screening. If the Common Third-Party Screening Tool generates a red flag which remains unresolved, the carrier proceeds to step

Depending on their own policies, some carriers may seek to resolve a red flag by making enquiries with the shipper rather than immediately proceeding to an inspection, while other concerned carriers may not seek to follow this approach. The carrier may also decide to use the ‘Reactive’ Inspection System on a case-by-case basis after internally assessing notifications of the Common Third-Party Screening Tool and/or information coming out of its individual screening.

Step #5

The fifth step, subject to carrier’s decision to proceed with this, is the triggering of the ‘Reactive’ Inspection System (by physical incidents or unresolved red flags generated by the Common Third-Party Screening Tool).

Step #6

The sixth step is carrier’s choice of a container inspection company from a Database of Approved Container Inspection Companies. The database consists of companies which are approved by individual carriers based on meeting conditions that represent minimum industry best practice safety standards and criteria tailored to the needs of this system. The Vendor will be required to establish and administer the Database of Approved Container Inspection Companies.

Step #7

The seventh step is an inspection being conducted by a container inspection company in a standardized way. This is based on minimum safety standards and criteria, comprising two pre-conditions to an inspection and 18 items to verify during an inspection.

Step #8

The eighth step is the production of container inspection outcomes, positive or negative. These results are communicated by the inspection company to the carrier for appropriate decision-making based on its internal policy.

The carrier also notifies the Vendor of the Common Third-Party Screening Tool for the purposes of potential actions relating to modifications to the Shared Keywords Library as appropriate and to the shipper’s suspension from the Verified Shipper Database depending on safety criteria.

Third-party provider submissions

Yesterday, the WSC started the process of finding an independent third-party provider with high integrity to develop the digital tools and manage the Cargo Safety Program process for cargo screening and inspections. The deadline for submission of a proposal is Sunday, 26 November at 23:59 GMT.

This common safety approach will significantly mitigate the risks associated with non-declared or improperly declared, labelled or packed dangerous goods across the supply chain. At the same time, the system will streamline the transport of compliant dangerous goods in line with national and international regulations.