Norsepower Oy Ltd., announces a joint development project with Shanghai Waigaoqiao Ship Building Co., Ltd (SWS) both developing an energy efficient dual fuel very large crude carrier (VLCC) design, aiming to enhance fuel efficiency and reduce emissions. Under the agreement, Rotor Sails were implemented in the VLCC design for improving the fuel efficiency and reducing emissions.

Specifically, the effects of the installation of Norsepower’s Rotor Sail solution was revised using computational-fluid dynamics (CFD), and confirming the possibility of achieving a 6-10% fuel and emissions saving, depending on operating routes.

Additionally, the technology can be installed to new vessels or retrofitted on existing ones.

Given its automation, the technology is able to sense when the winder is getting stronger to deliver fuel savings, at which point the rotors start automatically – optimising crew time and resource.

Jukka Kuuskoski, CSO of Norsepower, commented that

We are very pleased to be collaborating with SWS, Lloyd’s Register and ABS on this project. This partnership allows industry leading organisations to explore cleaner solutions for the oil tanker market and drive shipping towards a modern era of auxiliary wind propulsion for the global maritime industry.

Norsepower’s Rotor Sails have already been installed onboard three vessels; Bore’s M/S Estraden, a 9,700 DWT Ro-Ro carrier, Viking Line’s M/S Viking Grace, an LNG–fuelled cruise ferry, and Maersk Tanker’s 110,000 DWT Maersk Pelican.

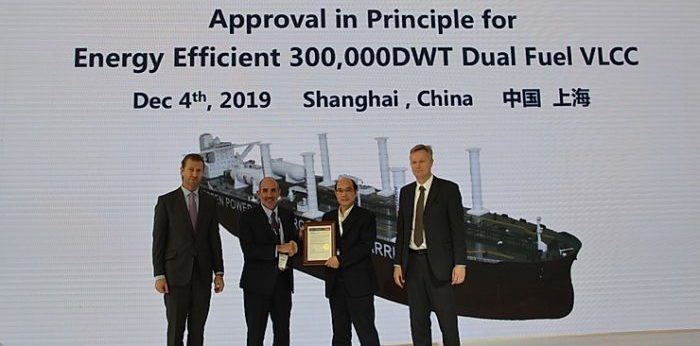

The official signing took place during a press conference arranged by SWS at Marintec China in Shanghai.