As UK MAIB reports in its most recent Safety Digest, a recently built specialist cargo vessel was on passage when a temperature probe in the main propulsion system gearbox became detached from its fitting.

The incident

Operating at 25 bar, the gearbox oil ejected the probe from the orifice followed by an oil jet that impacted engine room air supply trunking and sprayed a major part of the engine room, including one of the running main engines.

The gearbox low oil pressure alarm sounded on the bridge and within a few minutes the vessel’s engineers had attended the engine room and declutched and stopped the engines. The master was informed of the extent of the oil spray and the vessel went to emergency stations the designated firefighting crew got dressed and donned their breathing apparatus.

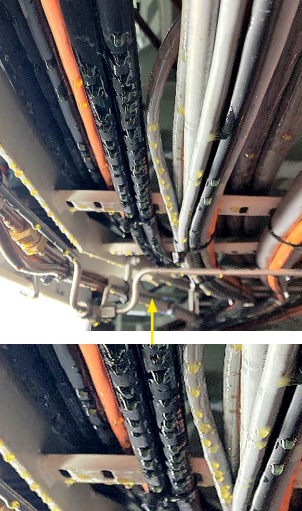

The oil had saturated the main engine exhaust lagging, which had started to smoke. Proactively, the engineers had prepared for ignition and brought wheeled foam fire extinguishers to the scene. A few minutes later, the oil-soaked lagging ignited but was quickly smothered in foam. Subsequent small fires were similarly dealt with. The vessel was able to make its way to port, where an investigation was started that involved the shipbuilder and gearbox manufacturer. Before the vessel could leave port, the contaminated lagging was replaced, electrical cable trays and affected electrical connections were cleaned and checked, various electrical motors were overhauled and the engine room was washed down.

The investigation identified that the temperature probe was held in place by a pipe compression fitting that had not been fully tightened during the vessel build. Once the fitting slackened further, there was nothing to stop the oil pressure forcing the probe out of the gearbox.

Lessons learned

- Action: The crew responded well to an unexpected event that could easily have resulted in a major fire. Not only did they quickly go to emergency stations but they placed foam extinguishers near the oil‑soaked engine so that lagging fires could be quickly dealt with. Knowing your emergency procedures and equipment pays dividends when a real situation occurs.

- Monitor: New vessels always have snags, some of which only make themselves known once the vessel is underway. A heightened level of equipment monitoring during the first few months of a new vessel’s life can catch some but not all. A good understanding of the different systems on board will therefore be vital in mitigating the consequences when the unexpected happens.

- Equipment: Although it was a marine gearbox, the design of the probe fitting was insubstantial in terms of the operating environment and the consequences of it coming loose. Poorly designed equipment increases the risk of injury to the crew and can force them into undesirable workarounds. In this case, the manufacturer produced a redesigned fitting and probe housing that would prevent reoccurrence and allow the probe to be changed while the propulsion system was working.