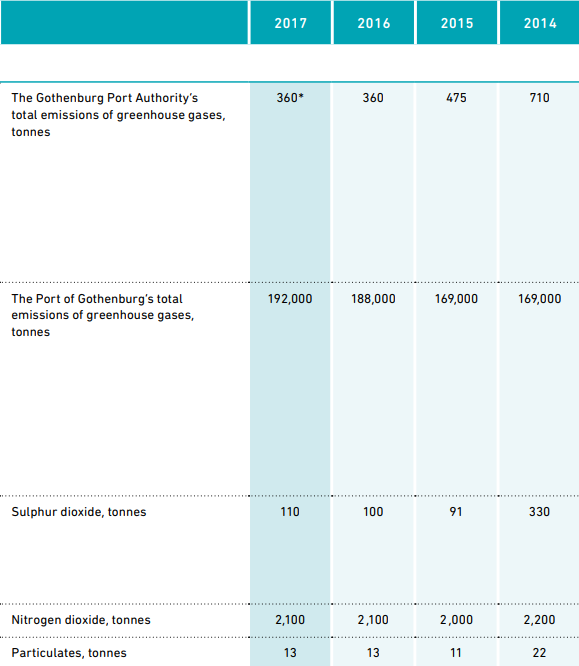

The Swedish port of Gothenburg issued its sustainability report for 2017 analyzing how it worked in the past year on steady improvements to reduce the operation’s environmental footprint, under its annual environmental plan, which is based on the City of Gothenburg’s environmental programme and includes three overriding goals: limited climate impact, reduced local environmental impact, and reduced resource consumption.

Measures for reduced environmental impact

Efficient handling of waste

In 2017 two teams were convened to devise specific measures to increase sorting and reduce internal operational waste, as well as waste from onboard operations. Measures are implemented continuously to improve and encourage more efficient waste handling within the company’s operations.

New facility reduces emissions of volatile organic compounds

In 2017 an Odour Control Unit (OCU) was installed in the Energy Port to reduce volatile organic compounds (VOC) and substances that generate odours when loading bunker oil.

Noise from port operations

In the past year, the port carried out a new survey to produce a detailed chart of which noise sources have the highest impact on the surrounding environment. The results show that the port has a relatively low noise impact on its surroundings in relation to the operations carried out, and the Port of Gothenburg receives fewer noise-related complaints than ports in other parts of the world receive.

Measures adopted this past year include rubberising of the metal ramps used to dock vessels. The company is also part of an international programme to examine the possibility of further cutting noise from vessels calling at the port. This includes agreeing on standardised measurement methods for better noise-reduction measures, and also the exchange of knowhow and experiences between participating ports. The two-year project will present its final results in 2018.

Climate-neutral company and energy efficiency

The company’s climate emissions for 2017 will be compensated through a project certified by the UN as per CDM Gold Standard. The company has long worked on energy efficiency measures in different parts of the operation and in 2017 conducted energy surveys that were reported to the Swedish Energy Agency. This work will continue in the coming year and will identify energy-saving measures for many of the port’s buildings and vehicles. In 2017 an optimisation project for heating the Energy Port’s pipe system was carried out, cutting energy consumption by about 20%.

Towards a higher proportion of quayside onshore connections

In 2017, work continued on getting a higher proportion of vessels to connect to onshore power connections. A survey was conducted in the first quarter, as per the company’s operational permit, to identify quays and vessels where onshore connection could deliver an environmental gain and local benefit. Based on the results, the port has worked with shipping companies to apply for financial support to create all-new electrical connections in the roro terminal. In 2017, 37% of vessels calling at the port had the opportunity to connect to quayside onshore power supply.

LNG bunkering

LNG bunkering increased in the port in 2017. For the first time ever, LNG was bunkered ship-to-ship, while loading was ongoing. This means that the Port already meets the EU directive which stipulates that it should be possible to bunker LNG in Sweden’s core ports by 2025.

Cooperation and incentives

The port has long worked to offer various financial incentives to the maritime sector through discounts on port tariffs for vessels with the best environmental credentials. This work continued in 2017, when 118 vessels received environmental discounts.

Further information may be found by reading the full report: