The NTSB issued an illustrated digest report, summarizing key safety issues and recommendations, on the El Faro sinking, the deadliest shipping disaster involving a US-flagged vessel in more than 30 years. Earlier investigations have attributed the disaster to the captain’s failure, as well as to inefficient safety procedures compliance onboard due to the owner’s lack of proper oversight.

–> Safety issues

- Captain’s actions

From early in the voyage, the captain made decisions that put his vessel and crew at risk, including:

- making only minor course corrections to avoid Joaquin

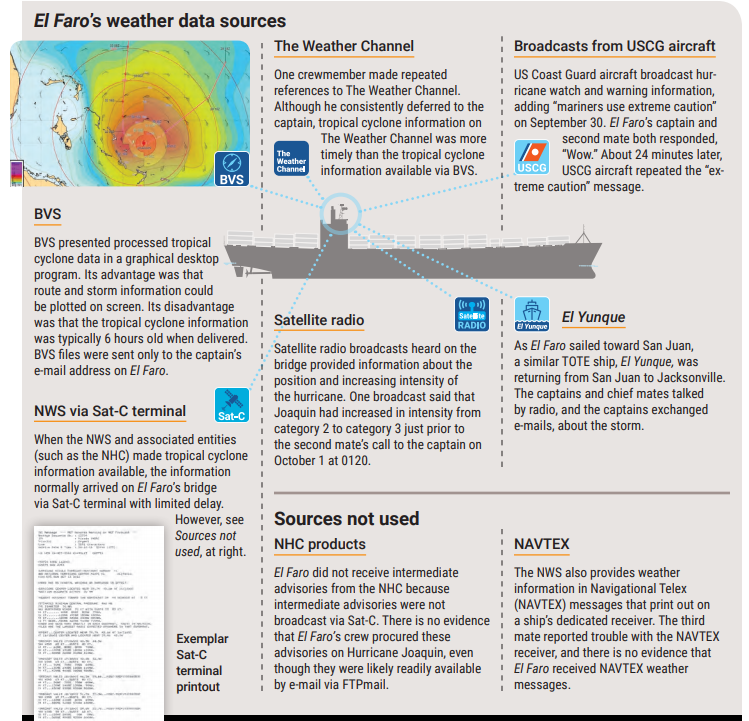

- relying on outdated weather sources

- declining to change course or return to the vridge, even after receiving three calls from deck officers when he was not on the bridge

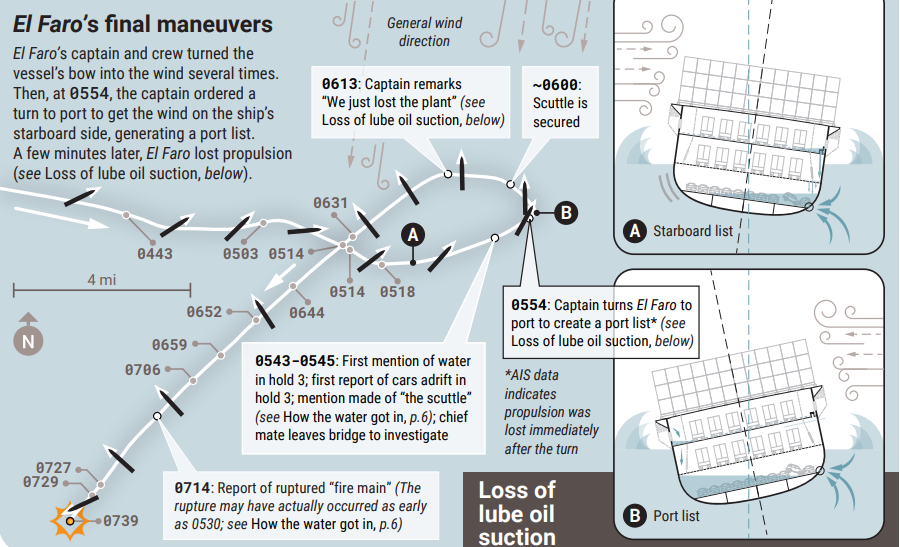

- introducing a port heel to shift water on the weather deck from starboard to port.

- Use of non-current weather information

The captain continually referred to hours-old weather information from BVS. Watchstanders on the bridge were routinely getting more current information from the Sat-C terminal and from programs on satellite radio.

- Late decision to muster the crew

After the ship lost propulsion, the Captain continued to voice his expectation that propulsion would be restored. The general alarm did not ring until 0727 and the captain did not muster the crew until 0728.

- Ineffective bridge resource management

Two crew of the bridge suggested that they disagreed with the captain’s decisions, but the captain disregarded their concerns. Although bridge resource management stresses assertiveness, the traditional maritime culture emphasizes on the captian’s authority onboard. TOTE had not effectively implemented BRM which involves modernizing centuries-old roles.

- Inadequate company oversight

TOTE disregarded captains as teh primary nautical experts. Lack of training in BRM was one area the company oversight failed. It also failed to train crew to use BVS, and on the cargo-loading program. Another failue was to track the vessel’s position relative to the storm.

- Company’s SMS

The SMS did not provide the officers and crew with necessary procedures to ensure safe passage, watertight integrity, heavy weather preparations and emergency response in heavy weather.

- Flooding in cargo holds

Water initially flooded into the cargo holds through an open scuttle. This lowered deck friction coefficients and likely contributed to loose vehicles in hold 3, which likle damaged emergency fire pump, allowing seawater to flood the hold faster than the vilge pumps could remobe it.

- Loss of propulsion

The sequence of events leading to loss od propulsion began with s sustained starboard list from the beam winds and later flooding of a catgo hold. The captian acred to to shift the starvoard heel to a port heel. The port heel in combination with momentary roll, likely allowed air into the lube pump, which triggered a shutdown of the main propulsion engine.

- Downflooding through ventilation closures

El Faro’s certificate of inspection required that cargo ventilation closures be kept open at sea when the vessel was transporting vehicles with fuel tanks. In heavy weather with a threat of Downflooding, it was crucial that crew understood that such closures must be secured to prevent flooding.

- Need for damage control plan

VDR did not show that the captain or crew consulted a plan procedure for damage control during the heeling, propulsion loss and flooding sequence.

- Lack of suitable survival craft

El Faro carried only open lifeboats. In addition, the severe weather combined with the ship’s list, made it unlikely that the side-mounted lifeboats could be boarded or launched.

–> Recommendations

The NTSB summarized recommendations as resulted from the extensive investigation:

- Better tropical cyclone forecasting, storm advisories and weather dissemination systems to improve the accessibility and quality of forecasts for mariners

- Engines and other critical machinery that work at greater angles of inclination (e.g. despite more listing)

- Lifeboats that can be launched at still greater angles of inclination, so that they can be launched even if engines or other machinery fail.

- Enclosed, not open lifeboats

- Protected seawater supply piping in cargo holds

- Remote open/close indicators for watertight doors and hatches

- Guidance that actions intended to correct a list can be dangerous with cargo adrift

- Class-approved damage control plans/booklets onboard regardless of build date

- Review of the inspection program and improved oversight

- Lifesaving appliances updated at least every 20 years

- Personal locator beacons for crews

- Better VDRs and VDR testing

- Weather reporting by ships to global authorities every 6 hours at fixed times, using AIS

- Appropriate BRM and meteorology training for deck officers

- Improved processes, documentation, training and shoreside support for TOTE

- External audit of TOTE’s SMS

- Functioning weather instruments on TOTE ships

- Heavy weather procedures on TOTE ships that address oil levels in critical machinery.

Explore more herebelow: