In the second edition of UK Maib Safety Digest, it is noted how a third engineer got injured and suffered severe scalding burns during cleaning the auxiliary condenser.

The incident

The third engineer of a chemical tanker had been tasked with cleaning the auxiliary condenser, a familiar task.

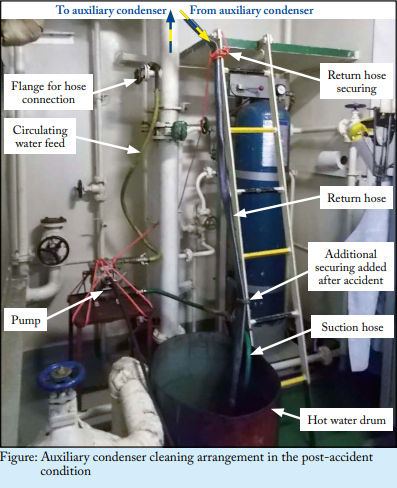

While the chief engineer had carried out a toolbox talk with the third engineer and a motorman beforehand. The third engineer set up the cleaning equipment: a drum of hot water, a circulating pump and hoses to supply and return the hot water through the condenser.

The return hose ran from the top of the condenser back to the drum and was secured at the upper end of a nearby ladder.

Following there, the third engineer started the pump and stood near the drum while he prepared the cleaning chemicals. The water was discharging from the return hose in fits and starts, and the free end was moving around in the drum.

Suddenly the end of the return hose fipped out of the drum and sprayed scalding hot water over the third engineer.

The motorman stopped the pump and raised the alarm. The injured third engineer was given first-aid onboard before he was evacuated and transported to hospital. He had suffered severe scalding burns to his upper body and was of work for more than a month.

Lessons Learned:

- Consider securing arrangements carefully when rigging equipment for cleaning or other maintenance tasks. In this case the return hose fipped out of the drum because the securing arrangement at the top of the ladder caused a bottle neck effect and there was no securing at the lower end to prevent the moving hose escaping the drum.

- Never underestimate the danger of hot water and the risk of scalding. If possible, check circulating arrangements with water of a lower temperature before introducing water hot enough to cause injury. In this

case covering the drum might have been another way to reduce risk by placing a physical barrier between the hazard of the hot water and the crew.