In its first Safety Digest for 2021, the UK MAIB describes a case where a lifting gear crashed to the deck, causing serious head injury.

The incident

The deck crew of a general cargo vessel were getting ready to load wind turbines for transportation. The first step was to use the vessel’s crane to hoist the wire strop hatch lifting gear out of its stowage in preparation for opening the cargo hatches.

Prior to work commencing, the chief officer gave a safety brief including an instruction that crew were not to stand underneath the crane’s hook. Two ABs then entered the ventilation duct space where the lifting gear was stowedand connected it to the crane’s hook using a fibre strop.

The ABs then climbed out of the duct space and stood on the deck edge ready to help guide the lifting gear as it was hoisted out.

As the lifting gear was being raised, it snagged on the edge of the duct space. The chief officer ordered the crane driver to stop while the two ABs freed the snag by hand, then the lifting operation was restarted.

Soon after, the lifting gear snagged again; the chief officer saw this and ordered the crane driver to stop.

However, this order came too late as the fibre sling had parted under tension and the lifting gear crashed to the deck, striking both ABs, one of whom suffered a serious head injury.

Lessons learned

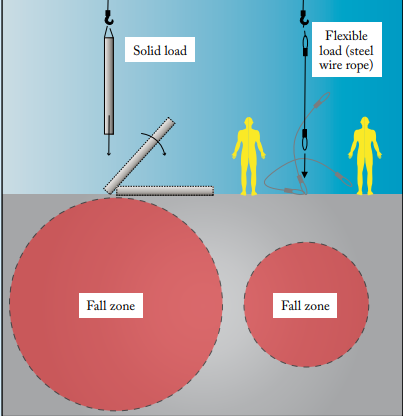

- During lifting operations, it is vital that crew avoid the hazardous fall zone under the suspended load. This is not just the area directly under the suspended load; it extends to the entire area where it is reasonably foreseeable that a load could fall.

- All lifting operations should have a safe plan, ideally a task specifc risk assessment and method statement. In this accident, the ABs were struck because they were standing in the fall zone, which had not been assessed as a dangerous area. At safety briefs or toolbox talks, crew should be reminded that anyone can call a halt to unsafe operations– in this case, any of the other crew could have alerted the chief officer that the deck ABs were in danger.

- The ventilation duct space was unsuitable as a storage for the lifting gear due to the snagging hazards, which the crew were aware of. The lifting gear had snagged before, including just prior to this accident. The previous snaggings should have served as a warning that the stowage arrangements needed to be reviewed or improved.

- All fixed and loose lifting gear should be regularly inspected and documented. The purpose of inspections is to check that the gear is being maintained in a satisfactory condition for safety-related operational use. After the accident, it was discovered that the fibre sling in use was in a poor condition and had not been recorded in the vessel’s lifting gear log. Although the breaking load of the sling was sufcient to hoist the lifting gear, it should have been disposed of due to its poor condition.