The Swedish Club has reviewed around 200 bulk carrier claims and carried out analysis on the statistics in relation to grains and soya beans.

As explained, the loading, carriage and discharge of bulk grain and oilseed cargoes present numerous challenges. There is a range of considerations for the crew to consider prior to and during the carriage of bulk grain or oilseeds.

An understanding of the common issues experienced during carriage of these cargoes and ways to avoid them may well assist in preventing cargo damage and claims, that is why the club provides key information about cargo claims in relation to grains and soya beans. The information includes, but is not limited to, the following:

- The most common type of claim (63%) was for shortage, especially during discharge (68%). These claims were most frequently reported in North Africa and China.

- Around 70% of shortage claims resulted from discrepancies between the vessel’s figures and shore figures.

- Claims in China increased in recent years, partly due to pandemic-related disruptions, including lockdowns, delayed vessels, difficulties for surveyors, and reduced interaction between crew and stevedores.

- Shortage claims contributed to 44% of the total claims cost, with an average claim cost of USD 35,000.

- Non-contribution towards General Average (GA) contributions made up 20% of the total cost, with an average claim cost of USD 800,000.

- Wet damage accounted for 13% of the total cost, with an average claim cost of USD 37,000.

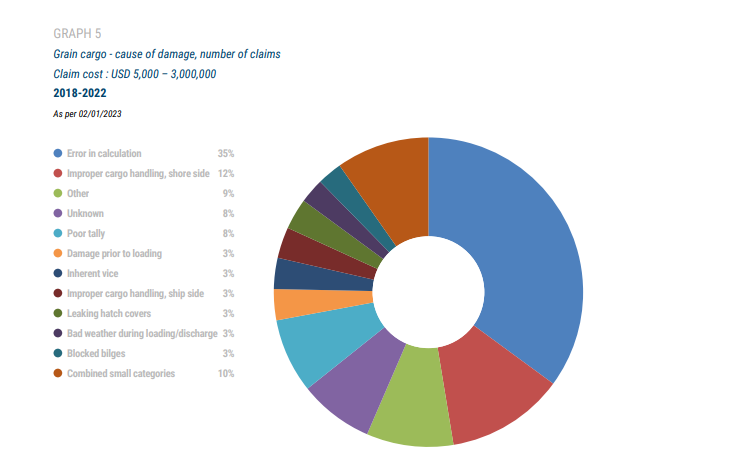

- The most common cause of damage was an error in calculation, which effectively is a shortage claim, representing 35% of total claims, with over 80% occurring at the discharge port.

- The second most common cause of damage was improper cargo handling on the shore side, contributing to 12% of claims and equally likely to occur at the discharge or loading port.

- Most claims occurred at the discharge port (68%), followed by claims during the voyage (16%), and only 10% occurred in the loading port.

- In the event of damage at discharge, it is essential to accurately record the location of damaged cargo in the hold. A local surveyor should be appointed to document cargo condition, inspect damage, and obtain a cargo temperature profile during discharge.

- Sampling superintendents should be appointed to take representative samples of the grain during discharge, with additional samples for sound and damaged cargo categories.