As part of International Marine Contractors Association’s monthly Safety Flashes, there is a case where a steel deck plate falls from the pipelay tower.

The incident

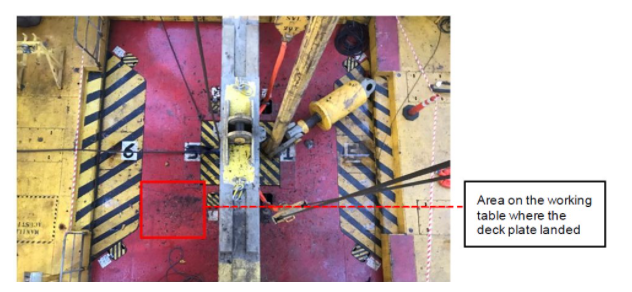

A large steel deck plate fell 9m from a pipelay tower to deck. The incident occurred on a vessel in dry dock, during which testing and inspection of the pipelay tower was taking place.

As explained, a rope access technician stood on one of the steel deck plates located around the mid centralisers.

The bolts securing the deck plate failed resulting in the deck plate upending and then falling to the deck below. The area below had been barriered off before work started. No-one was hurt.

On inspection it was noticed that the deck plate fixings were heavily corroded, with three of the four securing bolts providing no support.

Findings

- This deck plate and others found were not part of the original pipelay tower structure, nor on any vessel drawings.

- No change management or design engineering was carried out.

- Incorrect size and material grade of bolts were used.

- The deck plate was only supported on the rear section, and no support bracket had been installed underneath the plate where the technician stood.

- The task was being controlled under a Permit to Work complete with a task specific risk assessment.

- There was effective barrier management in place preventing persons from entering the Drop Zone.

- Good working at height practices were being used by the work party.

Lessons learned

- Ensure all gratings, steel deck plates and their fixings installed at height are inspected as part of a routine inspection program.

- Ensure equipment modifications are controlled through the change management process.