In its latest Safety Flashes for December, IMCA focused on a case where an unexpected truck movement caused rigger to fall off a ladder.

The incident

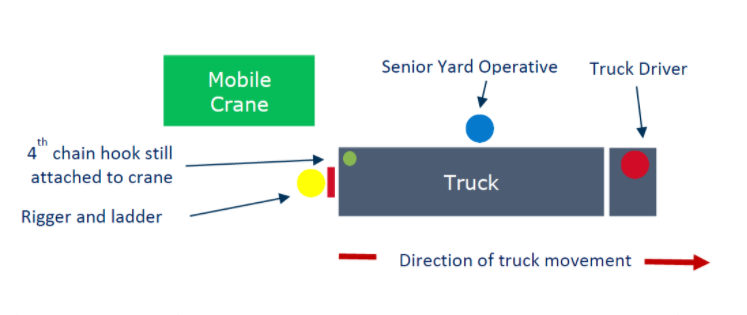

An unexpected movement of a container loaded truck during disconnection of the container’s rigging, caused a rigger to fall off a ladder leaning against the container.

Two containers were being loaded onto a trailer truck using a mobile crane. The supervisor conducted the toolbox talk before starting work. The riggers removed the container’s rigging (chain hooks), using a ladder to access the connection points.

The first container was loaded without incident. The second container was loaded onto the trailer and the riggers began to remove the chain hooks whilst the supervisor and driver secured the twist locks.

To access the 4th and last chain hook the rigger positioned the ladder against the rear of truck trailer. After securing the twist locks the driver went to the cab.

He checked the side mirrors and could only see the supervisor, and so proceeded to drive forward, assuming the lifting crew had already de-rigged the container.

Findings

- The supervisor did not provide the driver with an induction or briefing when he arrived at the yard.

- The Permit to Work for Working at Height indicated that a free standing work platform was to be used, but this was not used.

- The driver assumed that he was clear to drive forward.

- The Task Risk Assessment did not assess the risks introduced by or to the driver.

Lessons learned:

- Ensure clear and fully understood communication with third party plant operators – the truck driver in this case – before starting work.

- Ensure formal control of work, instructions, risk assessments and communications protocols are in place for third party drivers and other personnel.

- Consider keeping the driver away from the job completely until the lifting operations is complete. This prevents drive off and protects the driver from potential lifting issues impacting the driver’s cab.