The Australian Transport Safety Bureau (ATSB) launched a report about the injury of two crewmen on a bulk carrier, highlighting the importance of following procedures and applying best practice for safer operations.

The Incident

On 11 January 2018, a team of six crewmembers was conducting cargo hold cleaning and painting under the supervision of the chief mate on board Berge Daisetsu bulk carrier.

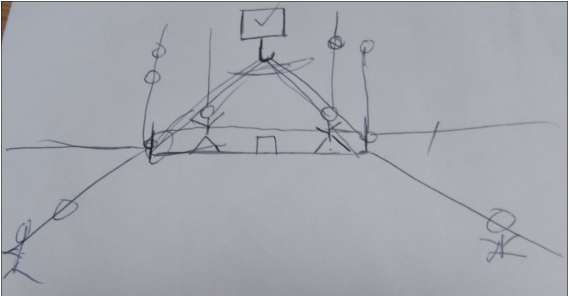

While working aloft, on a jury-rigged platform suspended from a cargo crane, the crane falling block and hook caught and then suddenly released from the hatch coaming. That resulted in shock loading of the platform and serious injuries to two crewmen.

Probable Cause

According to the investigation, before beginning operations, the crewmembers discussed, made plans and completed a risk assessment. Yet, given that the work was not conducted according to the company’s safety management procedures or industry best practice with regard to risk management and working aloft permit requirements.

Also, another cause was that the crane was being operated with its working limits bypassed when used to support the ship’s crew during the painting task. This enabled the crane to reach a position which allowed the block to contact and catch on the hatch coaming.

The fall arrest equipment that the crew used was incorrectly attached; This means that if any of the crewmembers fell from the platform the equipment would not have worked as it was supposed to, resulting to serious or fatal injuries.

Actions taken

Following the incident, ATSB and Berge Bulk Maritime continued to safety actions so that they could prevent a potential incident.

Berge Bulk Maritime proceeded to the actions below:

- completed on board working aloft training of all staff;

- completed on board training in bulk carrier personal safety and environmental protection including working safely in cargo holds and the correct donning and use of personal protective equipment;

- added a mandatory working aloft training module to fleet-wide on board training programmes, which is repeated every two years. This programme includes modules on working aloft risk identification, safe access at height and safe methods of work at height.;

- completed the fleet-wide purchase and supply of Class-approved work platforms for work aloft to all company-owned geared bulk carriers;

- commenced a programme to have all fleet geared bulk carriers’ cranes modified and approved for personnel lifting at scheduled dry dockings;

- engaged an external consulting company to conduct a fleet-wide assessment of safety maturity by measuring the company’s level of safety practice and how well this is embedded in the behaviour and belief of employees.

Explore more by clicking on the PDF herebelow