The Mærsk Mc-Kinney Møller Center for Zero Carbon Shipping (MMMCZCS) has analyzed the technical, economic, and environmental impacts of converting tankers for alternative fuels.

The “Preparing Tanker Vessels for Conversion to Green Fuels” report outlines the project results related to converting tankers to methanol or ammonia fuels. Insights from project partners were used to understand the technical requirements and costs of converting from fuel oil to methanol or ammonia and from liquefied natural gas (LNG) to ammonia.

Vessel design and operational considerations

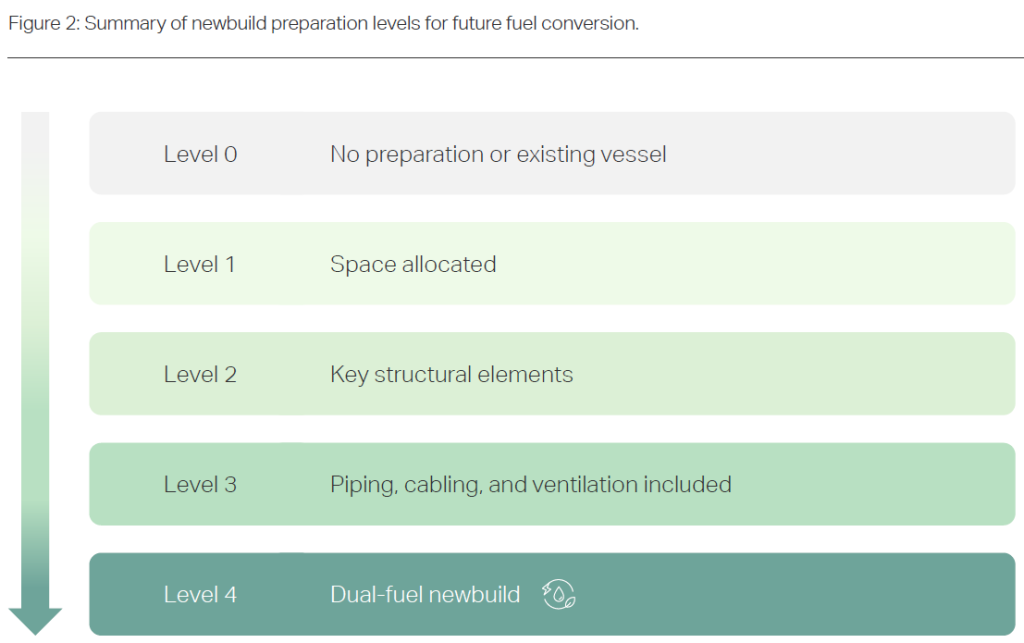

The report considered reference designs for two types of tanker vessels: LR2 and VLCC. These vessel types, among the largest in the tanker segment, often travel long routes and have high fuel consumption, making them suitable for illustrating the economic and environmental impacts of different vessel conversion choices. Five levels of preparation for alternative fuels were defined for each vessel design, ranging from no preparation (Level 0) to a dual-fuel newbuild ready to operate on methanol or ammonia (Level 4).

Alternative fuels are less energy-dense, requiring more storage space than fossil fuels for the same distance traveled. Therefore, the interaction between fuel storage capacity, cargo capacity, and vessel range was a key consideration. Options for transitioning the vessel to a reduced but still commercially relevant range after conversion were included in the study.

For the LR2 design, storage requirements for alternative fuels can be met using tanks located on the deck without affecting the vessel’s range, leading to minimal impact on the LR2’s standard parcel size and cargo capacity. However, additional tanks and fuel volume will decrease the vessel’s deadweight tonnage (DWT).

For the VLCC design, maintaining the same range after conversion to methanol or ammonia would require installing fuel tanks in the cargo space, leading to a loss of cargo capacity. A full-range VLCC operating on ammonia is generally considered commercially unviable. However, operating the VLCC with a reduced range after conversion to either methanol or ammonia allows all fuel tanks to be located on the deck, preserving the cargo space. The reduced range option for the VLCC is based on a trade route from the Persian Gulf to the Far East, relevant for this segment.

Techno-economic analysis

For the LR2 design, the model indicates that the total add-on cost of newbuilding and conversion to operation on methanol or ammonia, depending on preparation level and range, is:

- 14-27% of the cost of a standard fuel oil newbuild for fuel oil-methanol conversions

- 25-42% of the cost of a standard fuel oil newbuild for fuel oil-ammonia conversions

- 47-62% of the cost of a standard fuel oil newbuild (or 21-34% of the cost of an LNG newbuild) for LNG-ammonia conversions

Considering the different preparation levels, a dual-fuel newbuild vessel makes the most economic sense if operation on the alternative fuel is expected in 5-7.5 years when converting from fuel oil or 10.5-12 years if converting from LNG. For vessels built for later conversion, the best preparation level depends on the conversion timeline, impacting capital expenditure (CapEx) at the newbuilding stage by 1-3% of the cost of a fuel oil newbuild or around 2-4% of the cost of an LNG newbuild.

For the VLCC design, maintaining the vessel’s full range after conversion is generally not economically viable. Assuming options with reduced range after conversion, the estimated total add-on cost of newbuilding and conversion, depending on preparation level, is:

- 17-29% of the cost of a standard fuel oil newbuild for fuel oil-methanol conversions

- 31-45% of the cost of a standard fuel oil newbuild for fuel oil-ammonia conversions

- 50-63% of the cost of a standard fuel oil newbuild (or 17-28% of the cost of an LNG newbuild) for LNG-ammonia conversions

Assuming a reduced range following conversion, a dual-fuel newbuild is the most economical option if operation on alternative fuels is expected within 4-6 years. For conversions, the choice of preparation level depends on the timeline, impacting newbuild CapEx by 1-6% of the cost of a fuel oil newbuild or 5-7% of the cost of an LNG newbuild.

Conclusions

The analysis indicates that converting tanker vessels to alternative fuels after five or ten years of operation on fossil fuels significantly reduces lifetime operational greenhouse gas (GHG) emissions. The CO2 emissions from the conversion process are minimal, equivalent to around 0.5% of the vessel’s lifetime operational emissions using fossil fuels.

Key takeaways:

- Converting tankers to green fuels can be technically and economically feasible when considered within the context of fleet transition planning and asset age profiles. The industry has the necessary technology and engineering knowledge to achieve such conversions. The economic impact varies depending on the desired green fuel and vessel range chosen, with the most cost-effective option being conversion from fuel oil to methanol, followed by ammonia.

- Conversion to alternative fuels impacts a vessel’s operating envelope due to the energy density of the alternative fuels and their corresponding fuel tank size requirements. To maintain the same operational range as with fossil fuels, shipowners must consider either adding tanks on deck (impacting deadweight tonnage) or using part of the cargo capacity for fuel tanks. This analysis focuses on options that reduce the vessel’s operating range but preserve its cargo capacity, with solutions believed to have commercial applicability.

- Conversions after ten years of operation on fossil fuels can still yield considerable environmental benefits. However, the financial viability of such a CapEx investment at this point in the vessel’s lifetime must also be considered.