In its 57th issue, CHIRP pays attention to an engine room rating operation that had to be conducted by the Chief Engineer, who declined to conduct the operation in the machinery spaces, due to the lack of safety measures, an act that in the beginning led to the Chief Engineer’s exclusion from engine room duties.

Specifically, it was when the engine room rating requested a permit for working at heights and asked for assistance, such as scaffolding, to be established to allow safe access, that the Chief Engineer refused to issue the permit- causing their relationships to spiral downhill.

The Reporter told CHIRP that

I am assigned as an engine fitter and was told to do a job in the engine room but there was no proper permit for the job or proper safety requirements like scaffolding. When I refused to do this job, the Chief Engineer charged me with refusing to work and told me I would be relieved at the next port. I am currently excluded from engine room duty.

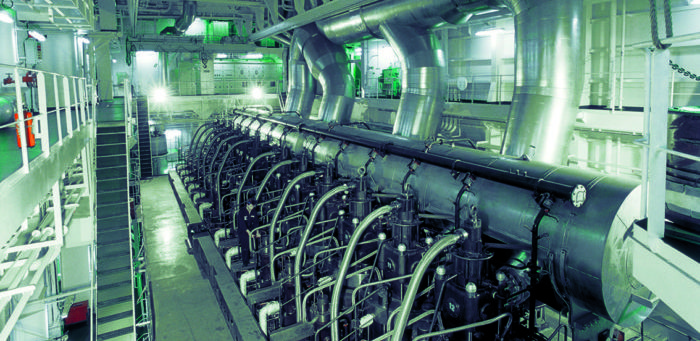

The job in particular was the installation of a new steam condenser and fuel coolers with associated pipework and brackets and it involved working between 2 and 5 meters above the engine room deck plates.

The reporter who was already six months into a nine-month contract had previously worked on the ship, was then apparently called to the bridge for a hearing at which he was found guilty of ‘insubordination, incompetence and inefficiency’ and was abruptly discharged with repatriation from the next port, at his own expense.

Notably, the main safety concern appears to be the poorly informed safety regime inside the engine room. Some of the other issues highlighted by the correspondence from the reporter appear to be outside the responsibility of CHIRP; Yet, it is made apparent that

the situation onboard involved several separate but interrelated issues, and further that onboard relationships had completely broken down

… as CHIRP comments.

On their part, CHIRP advised the reporter to contact his employment office, the ITF and ISWAN regarding his employment status and welfare issues. In fact, the reporter then confirmed that his employment office and the ITF had been contacted and responded.

With respect to the safety concerns, CHIRP then contacted the company DPA who verified that the safety issues are still under investigation and that reporter had not been charged any airfare.

CHIRP subsequently learnt that the reporter was safely repatriated and had been given 2 months compensatory basic wages for early repatriation.

Members of the MAB applauded the positive response and engagement by the DPA. They further noted that “any working aloft requires a permit to work; a safe platform to work from; a ladder that can be used to access the safe platform or even the job site for inspection purposes,” while underlining that most tasks that require two hands cannot be carried out safely from a ladder, as a ladder requires three points of contact.

Moreover, CHIRP highlights that the situation may have been prevented, if a formal task or job risk assessment involving both the chief engineer and the reporter plus the ship’s safety officer would have highlighted any hazards.

Whatsoever, the MAB members stress that there is and must be a chain of command or hierarchy on board a ship and this cannot be undermined. However,

seniority carries responsibility and obligations with regards to man management and leadership skills which in this age of multi-cultural, multi-lingual and multinational crews can be very difficult.

Lastly, it is advisable that senior staff from all departments could attend some HELM (Human Element, Leadership and Management) courses available, prior to promotion or perhaps as a periodic refresher.

Before any job is carried out on the ship a job planning has to be done.A proper risk assessment of the job to be done is carried out . All the safety aspects of the job is to be discussed and agreed with the people involved with the job.The risk assessment form to be filled and appropriate signatures of the people doing the job is taken and recorded..This is done to ensure that the job is done safely and no unwanted accidents / accidents takes place.If this was done appropriately the above incident would never have tajen place