As UK MAIB reports in its most recent Safety Digest, a contractor prepared to remove two cylinder heads from a cargo ship after carrying out engine maintenance.

The incident

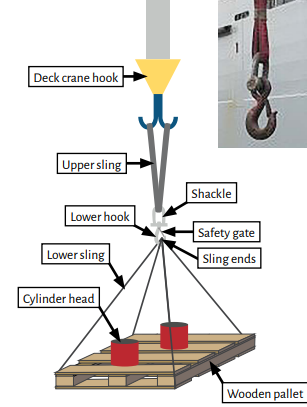

The heads were made of cast iron, weighed 280kg each and were strapped to a wooden pallet ready to be lifted ashore using the ship’s deck crane. Two slings were passed through the pallet and the four ends were attached to a lower hook, which was joined to two upper slings by a shackle; these upper slings were suspended from the deck crane hook. The four sling ends rested one on top of the other in the throat of the lower hook and so it was impossible to close the safety gate.

The initial lift of the wooden pallet was successful but when it was about 10m above the jetty the uppermost sling end slipped from the lower hook and flipped the pallet over, causing the cylinder heads to fall. Thankfully, the lifting operation plan ensured nobody was standing below the suspended load and damage was minimal; the falling cylinder heads caused a dent in both the jetty and the operator’s wallet.

Lessons learned

- Procedure: Adherence to COSWP is essential during lifting operations, particularly its instruction that loads should be lifted using certified lifting equipment that should be appropriate for the task. The cargo ship was equipped with a purposely designed set of forks with which to lift loaded pallets, but it was not used.

- Risk: Any lifting operation requires careful consideration, adequate risk assessment and supervision by a responsible crew member. There was an opportunity when the sling ends prevented the safety gate from closing to pause and reassess the lifting arrangement to make it safe.

- Margin of safety: Clearing people away from the immediate area before the lifting operation ensured that the consequences of this accident were purely mechanical and financial. The outcome would have been much worse had anyone been standing below the suspended load when it fell.