The International Union of Marine Insurance (IUMI) presents technical information on electric vehicles (EVs) and cargo fire parameters as the result of their carriage.

Technical information

As IUMI explains, battery electric vehicles are usually fitted with a lithium-ion traction battery, which is encapsulated and shielded by the vehicle’s body. The battery pack consists of various battery modules, which in turn are comprised of several battery cells. The chemical process that produces electricity that can be used for the propulsion of the EV takes place within the battery packs. The battery system is usually placed in the vehicle floor or undercarriage, where it is protected from damage by an anti-crash frame.

Electric vehicles have extensive safety systems that will automatically shut down the power and isolate the battery pack when a collision or a short circuit is detected. An important safety feature of EV battery packs is their in-built battery management systems (BMS). The BMS monitors and controls the battery and is a crucial factor in ensuring EV safety. It safeguards both the user and the battery by ensuring that the cell operates within its safe operating parameters. It monitors the state of a cell as represented by parameters such as:

- Voltage: indicates a cell’s total voltage, the battery’s combined voltage, and the maximum and minimum cell voltages.

- Temperature: displays the average cell temperature, coolant intake and output temperatures, and the overall battery

- The state of charge of the cell to show the battery’s charge

- The cell’s state of health shows the remaining battery capacity as a percentage of the original capacity.

- The cell’s state of power shows the amount of power available for a certain duration given the current usage, temperature, and other

- The cell’s state of safety is determined by overseeing all parameters and determining if using the cell poses any

Technical validation and safety tests are adapted to the respective manufacturers’ specifications for the battery packs and are usually inherent in the production processes.

State of charge (SoC)

State of charge (SoC) is an electrical cell’s or battery’s charge level compared to the total capacity of the cell or battery. Batteries at high SOCs have been shown to experience more violent reactions during thermal runaway. Testing has indicated that high SoC cells produce higher heat release rates, maximum temperatures, and concentrations of flammable and toxic gases during thermal runway events. However, while the SoC does affect the growth and peak heat release, it does not affect the total heat release.

Thermal runaway

Despite this inherently safe design, thermal runaway may occur if a cell is abused, e.g., by heat, mechanical damage, or overcharge. Thermal runaway can also occur as a result of a cell or battery manufacturing error.

When thermal runaway occurs, the cell is undergoing an unstable chemical reaction that is difficult to bring under control. At some point, the separator structure collapses and the electrodes touch, causing an internal short circuit and masses of heat, bringing the cell to ever higher temperatures and generating toxic and flammable gases. Cell heating will continue until the rise in temperature exceeds the heat that can be dissipated by the cell’s construction. This released heat will then increase and start to affect other nearby battery cells. When the generation of heat becomes self-sustaining—the heat releases energy, and the energy in turn releases more heat—the overheating propagates from cell to cell, and the battery is in thermal runaway.

The high safety standards integrated into EV traction batteries, including solid casings and the BMS, make the likelihood of damage to an EV battery pack and thermal runaway extremely low. However, in view of the low possibility for thermal runaway, the significance of the BMS as incorporated into EVs is particularly relevant. These safety systems prevent the battery cells from overcharging and undercharging and thus prevent thermal runaway. It is important to note that BMS are not incorporated into smaller, less sophisticated vehicles such as electric bikes or scooters.

Probability of fire in EVs

It is often said that EVs burn more often than internal combustion engine vehicles (ICEVs). However, as statistics continue to be gathered, they currently estimate that, in general, there are fewer fires from EVs compared with fires from conventional vehicles when driven over the same distance. Current statistics from Sweden indicate that the probability of an EV fire is lower than that of a fire in an ICEV relative to the total number of vehicles.

Fire intensity

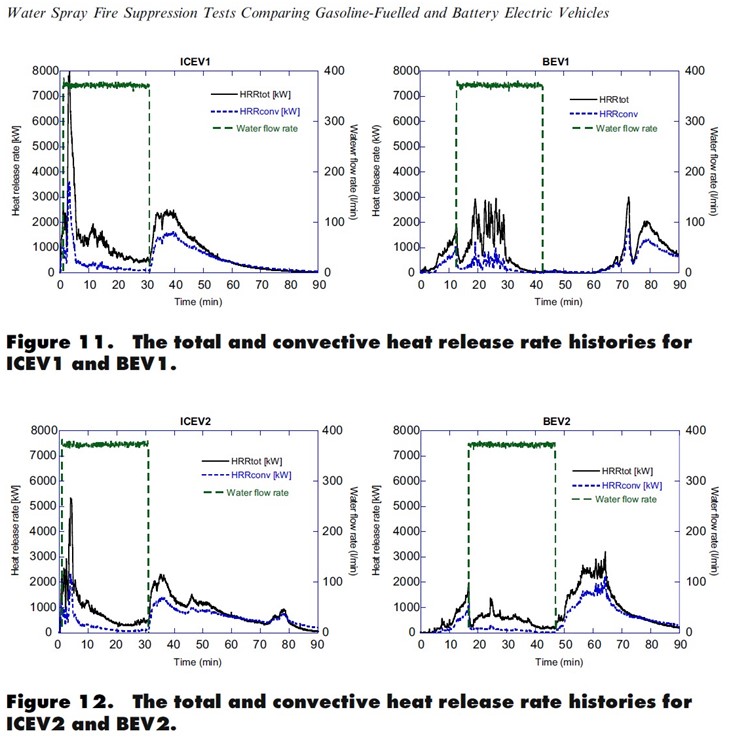

EV fires have often been claimed to be more intense than ICEV fires. In this regard, heat retention rates (HRR) from full-scale fire tests performed in recent years with modern vehicles, including both ICEVs and EVs, were reviewed.

The data compiled showed a minor difference in the total energy released during the fire (total heat release) between ICEVs and EVs. In this context, it is important to emphasise that the SoC affects the growth and peak heat release, but it does not increase the total heat released, as indicated in the following graph:

Despite the potential for thermal runaway, studies by the Danish Institute of Fire and Security Technology and NFPA have determined that EV fires, once established, are largely fueled by the car body and interior parts made from plastic materials and that the fire load is similar to that of internal combustion engine (ICE) vehicles.

Generally, approx. 20% of the fire load, regardless of its propulsion method, is from the energy source, and approx. 80% is from the exterior and interior of the vehicle. While the latter is largely comparable for all vehicles, the lower share related to the propulsion technology has a fairly limited impact on how to fight the fire, i.e., pool fires from gasoline vs. re-ignition in EVs.

Fire fighting

It is often stated that EV fires are impossible to extinguish. A thermal runaway in a lithium-ion battery is indeed difficult to extinguish unless the firefighting agents are injected directly into the battery to enable efficient cooling. If a fire breaks out in an EV (and in an ICEV also), activities in support of early detection and verification/confirmation, early fire suppression, and boundary cooling are critical actions to stop the spread of the fire to the battery and to adjacent vehicles.

A particularity of EVs is the risk of re-ignition, which tends to be higher for a longer period than for ICEVs. Precautionary measures to avoid re-ignition of the traction battery must therefore be taken for an extended period after a fire has been extinguished.

Toxic gases

Another aspect is related to the gases from EV fires, which are perceived as being extremely toxic. Hydrofluoric gases, which are highly poisonous, are indeed emitted from lithium-ion battery fires. In this context, however, it is important to consider that combustion gases from all types of vehicle fires are highly toxic and can cause incapacitation.

Carbon monoxide and hydrogen cyanide are common causes of death when smoke has been inhaled in a fire accident. Staying out of the smoke plume and wearing adequate personal protective equipment when dealing with burning or burned vehicles is crucial for all fires, regardless of the energy source of the vehicle.