The Shipowners Club issued the latest in a series of risk assessment articles, in cooperation with CTRL Marine Solutions, emphasizing on risk assessments from mooring and unmooring operations.

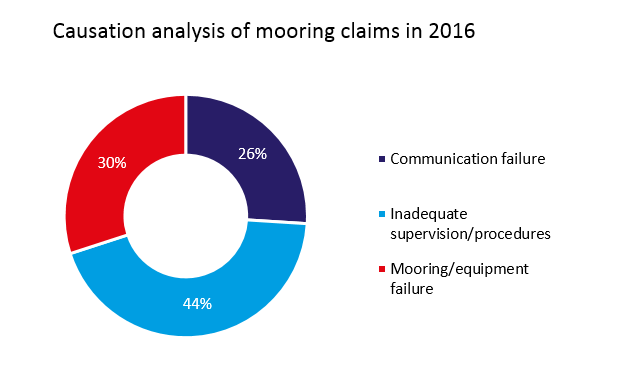

In 2016, the Club has experienced a high volume of claims which arose from three main areas of causation:

- Inadequate supervision/procedures : These include claims arising from a lack of supervision of the task, inadequate or non-existent procedures or a failure to comply with existing procedures.

- Communication failure : These include claims arising from communication failures between the various teams involved in mooring operations such as, the bridge team, the pilot and the deck mooring teams as well as the tugs/ shore mooring personnel.

- Mooring/equipment failure : These include claims which involved a failure of mooring equipment, mooring ropes and anchors used for mooring.

As explained, due to varied configurations at berthing facilities, mooring patterns may range from being simple and repetitive to complex, innovative and often ‘one-off’ operations. Whilst the simple/repetitive mooring operations may appear less challenging, the risk of complacency, leading to reduced situational awareness among personnel, may be enhanced and thereby increasing the possibility of an incident.

A typical mooring operation may involve a number of external parties such as pilots, tugs, longshoremen and at times mooring boats. The involvement of so many different groups may cause issues with communication especially if language barriers are a factor. Furthermore, weather and tidal conditions may also add to complexity of this operation.

As with any shipboard task, a large number of mooring related incidents may be avoided by conducting appropriate risk assessments. According to the Club, possible control measures require:

- Crew to be suitably familiarised and trained on mooring arrangements and equipment.

- Work areas to be inspected prior commencement of operations – to be free of any unwanted / loose material.

- Adequate illumination to be provided; no dark areas or shadow sectors.

- All immovable obstructions to be highlighted by tiger stripes and/or signage.

- Adequate personal protective equipment (PPE) to be worn by the crew.

- All necessary equipment such as mooring ropes/wires, stoppers, heaving and messenger lines and tools for mooring such as the axe, knife, crowbar etc, to be laid out in such a manner that they do not constitute any tripping hazard.

- Adequate supervision provided of the operation.

- Prominent display of snap back zone signage at entry points to the mooring areas.

- Tool box meeting to be conducted with all relevant crew and the task discussed with the aid of a mooring arrangement plan where appropriate.

- Surfaces to have non-slip coating as appropriate.

- Adequate crew to carry out the operation in a safe manner.

- Adequate personal protective equipment (PPE) to be worn by the crew.

- Constant supervision for proper coordination between the winch operator and the crew to prevent excessive tension on mooring lines or accidental operation of winches while the lines are being handled.

- Briefing of the dangers associated with working in snap back zone areas including those of mooring ropes and stoppers such as standing within a bight etc.

- Mooring ropes and wires to be properly inspected, maintained and replaced as appropriate to reduce the possibility of the lines parting during the operation.

- Life vests to be donned where there is a risk of crew falling overboard during mooring operations.

Explore more by reading the full document: