The Petroleum Safety Authority Norway (PSA) has completed its investigation of a lifting incident on the mobile facility Deepsea Atlantic on 8 March 2002, where a slip joint unintentionally ended up on the seabed.

The incident

The weather forecast for 8 May was for calmer conditions from 06.00 with an Hs of about 1.8 metres, becoming somewhat higher during the day.

This forecast formed part of the shift handover document for the deck department. It showed that the Hs was more than two metres up to 04.00 on 8 May, declining thereafter to 1.8 metres. It was then due to rise above two metres again from 00.00 on 9 May until 11 May. Historical values obtained from the facility’s own weather sensors confirm the forecast.

Stril Mar was asked to sail faster than the planned economy speed out to the location, and entered the 500-metre zone around Deepsea Atlantic at 05.55 for discharging and loading deck cargo, including load carriers, risers and slip joints.

Deck crew on the night shift started lifting load carriers from the ship with the starboard crane

After the WP had been activated, the crane operator conducted several lifts of load carriers from the ship together with the banksman and slinger. Five risers weighing 13.5 tonnes were then lifted down to the ship from the facility. All these loads were performed with the crane in single fall mode. Pennants dimensioned for risers were used, with a capacity of roughly 21.5 tonnes. Combining two pennants gave a capacity of about 30 tonnes.

When the lifts had been completed around 10.00, the work team took a break. The crane was then rerigged to double fall mode, but with the same pennants.

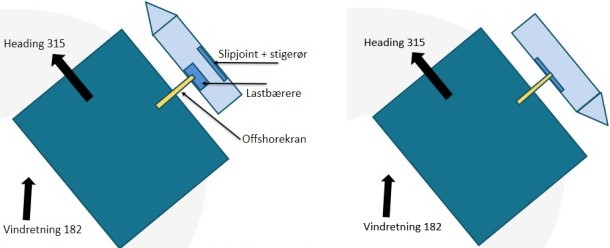

A riser with a buoyancy element was first lifted from ship to facility. The ship then lay with its port side against the facility. Before lifting the slip joint down to the latter, the ship was turned to bring its starboard side against the facility.

At about 11.18, the crane’s alarm log and witness observations revealed the following:

- The crane’s load computer was set to an Hs of zero metres.

- The operator lifted the slip joint. Then, with an outreach of about 27 metres, the crane received a series of alarms – 90, 100 and 110 per cent – and the AOPS was activated at 11.18.17. The crane’s overload alarm was heard on Stril Mar.

- The operator put down the load on Stril Mar’s deck. Once that had happened, the status of the overload alarms changed but the AOPS remain active.

- The lift was repeated once more with consequent alarms and overload alarm.

- The crane operator put down the load and the overload alarms were acknowledged by the crane, while the AOPS was acknowledged by the crane operator.

- The crane operator had a discussion with the deck foreman, who was working on the port side of Deepsea Atlantic, and they agreed to continue the lifting operation.

- The crane operator agreed with the master of Stril Mar that the ship would move closer to the facility.

Minutes later, at about 11.25-11.27, the crane’s alarm log and witness observations revealed the following:

- The starboard offshore crane started lifting the slip joint.

- Once the slip joint had been lifted a few metres and the height of the load was above the ship’s bulwark, Stril Mar began to draw away from the facility

- When slip joint has been lifted about 10 metres, several alarms were activated – including 110 per cent overload. In accordance with its logic, the crane then locked further operation. The AOPS activated immediately afterwards.

- The crane’s lifting winch began to pay out steel wire and the slip joint was lowered swiftly towards Stril Mar.

- The slip joint hit Stril Mar’s bulwark and continued into the sea.

- The crane operator activated the MOPS after the slip joint had entered the sea, and then on the crane’s emergency stop.

- When the MOPS was activated, all steel wire ran out and the load, including the hook block, went to the bottom. The wire parted at its end attachment to the drum, and the end attachment on the boom tip remained hanging.

Direct cause

Overloading of the crane occurred when lifting the slip joint from the supply ship. The load exceeded the crane’s capacity, which in turn activated the crane’s APOS and the load was rapidly lowered.

Underlying cause

The slip-joint weight specified in the manifest, and which formed the basis for planning the lift, did not accord with its actual weight.

The slip joint weighed 33 286 kilograms on delivery from the manufacturer, but two modifications had subsequently been made. Lifting clamps had been retrofitted, which added 856 kilograms, plus two melons for mechanical protection, which amounted to 1 304 kilograms. In addition, hydraulic control lines totalling about 100 kilograms had been removed.

The manifest from the logistics base, which formed the basis for planning the lift, specified 32 tonnes. The actual weight of the slip joint was subsequently measured to 35.2 tonnes. According to a manifest from 2021 used with a slip-joint lift, the weight was 33 tonnes. The riser including slip joint is part of the facility’s equipment and owned by Odfjell.

In addition, the crane operator did not halt the operation on receiving indications of crane overload.

Nonconformities

The PSA has identified the following nonconformities in connection with the incident:

- Inadequate safety clearance of activities

- Safety system for offshore crane

- Deficiencies in weight information for the slip joint

- Use of offshore crane.

The PSA’s investigation has now been completed. It has asked Odfjell Drilling to explain by 28 October 2022 how the nonconformities will be dealt with.

It seems to me that they were right on the edge of max capacity at the point control was lost. Is this normal practice or should a larger margin of error have been dictated?

Thanks,

Jack

PS – It took 20 years to complete this investigation and corrective actions are still not even in place?