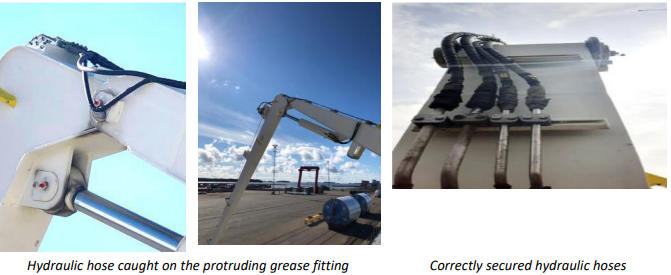

In its latest Safety Flashes, IMCA focused on a crane operation, which one of the hydraulic hoses caught on the protruding grease fitting of the boom bearings.

Incident

While retracting the outer jib of the boom during crane operations, one of the hydraulic hoses caught on the protruding grease fitting of the boom bearings, which could have led to a failure of the crane and hydraulic oil spill due to hose rupture.

What were the causes? What went wrong?

According to IMCA, the hydraulic hose routing on the crane boom was incorrectly lined up allowing the excess of the hose to catch the grease fitting, there was insufficient pre-use inspection of the crane.

Actions taken

- Stop Work Authority was used by Master and crane operations were suspended until a fix could be arranged

- The hose was fixed in a correct way to prevent it catching

- Proper pre-use inspection should be conducted before each crane operation

- Check your own cranes for the possibility of snagging or catching of this sort