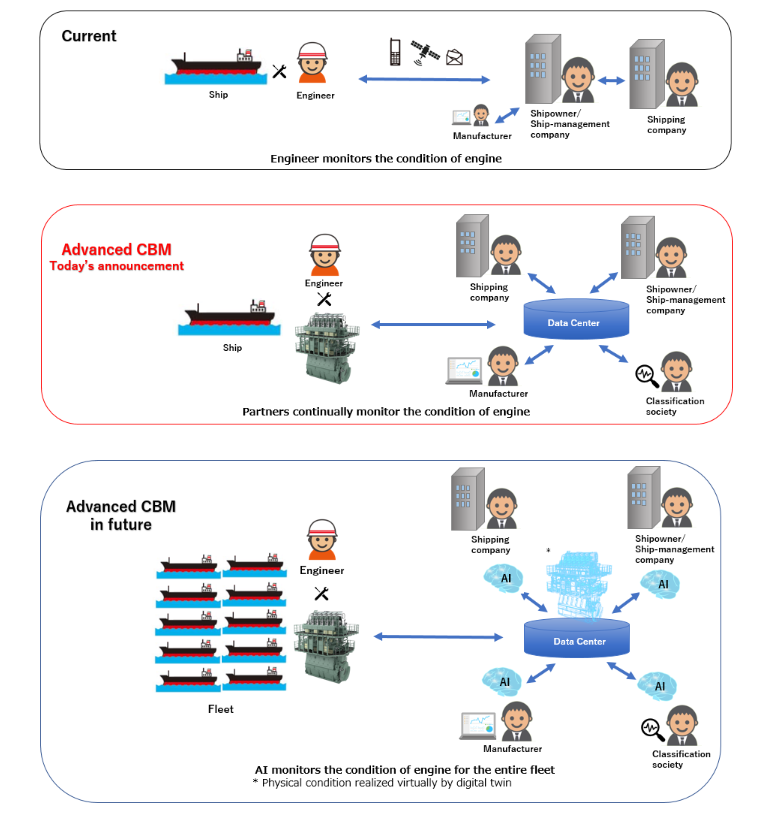

NYK Group finalised a research agreement to launch a developing condition-based maintenance (CBM) system, a new maintenance and management system to be used for the machineries of autonomous ships, while also has begun the verification of the system during the actual ship operation, providing a new way of fixing vessel’s machinery while it’s on operation.

Traditionally, the time-based maintenance (TBM) requires a vessel to pause operations for a specific timeframe, for inspections, even if there is no engine breakdown.

Today, given that digitalization enables a direct communication between the ship and the shore, NYK conducted a research on optimal maintenance.

Additionally to SIMS2, a ship information management system developed by NYK and MTI and allowing data-sharing among workplaces on land and sea in real time, a new sensor and equipment package are added in two different types of engines and main steam turbine, and detailed operational data such as vibration and temperature of bearing are to be collected. The condition of the engine will then be shared and constantly monitored by the classification society and engine manufacturers.

The system will be able to predict any potential failures and the remaining useful life (RUL) for the engine by taking advantage of manufacturer expertise to create optimal CBM guidelines and then verify them on actual ships.