TNO and partners in the Green Maritime Methanol Project published a new report on methanol. The paper analyzes the technological and economic viability of methanol as a marine fuel for the Dutch short-sea shipping sector.

The analysis on the availability of methanol as a fuel for maritime for shipping and its applicability for the Short Sea maritime operations has delivered several conclusions on the different levels of supply chain levels.

More specifically, regarding methanol production, the report says that there is global potential for viable production volumes of methanol. Multiple production routes are possible, including production based on fossil fuels, waste stream, bio mass and from electrolysis techniques using hydrogen together with carbon (captured from the air);

Regarding bunkering, truck-to-ship bunkering is considered as the most viable option for early adopters of methanol, while shore-to-ship bunkering can be further developed for certain vessel types such as ferries and port vessels. On the other hand, ship-to-ship bunkering is not expected to emerge until the market is further matured, but this has the option to dramatically increase availability and distribution in multiple ports supplied by the same bunkering vessel.

However, according to the report, some modifications of ship designs and engines would be necessary. Namely, chemical and physical characteristics of methanol require certain ship design modifications in order to maintain reliable and safe ship operation. Because of the liquid state of methanol and its specific safety requirements, some vessel adaptations are necessary for bunkering process, on board storage, in handling and processing, and its end-use in combustion engines;

As far as the safety of the fuel is concerned, methanol’s ; lower heat radiation from combustion decreases firefighting risks, while water solubility significantly limits the detrimental impact of a potential environmental spill. Nevertheless, methanol is volatile, has a low flash point and is toxic to humans. For this reason, the report requires due attention regarding safety. Provided that methanol fuel bunkering and handling can be kept separate from any other activities on board, it is possible to design fuel systems which provide acceptable safety;

In addition, another in favour of methanol is that there are already several successful pilots of vessels operating with methanol, therefore the technology readiness level is considered to be TRL 6.

What is more, whilst the energy density of methanol is only around half that of MGO or HFO, it is still relatively competitive in comparison to other alternative fuels, particularly hydrogen. Moreover, it potentially can be handled by most existing diesel systems with only small adaptions required.

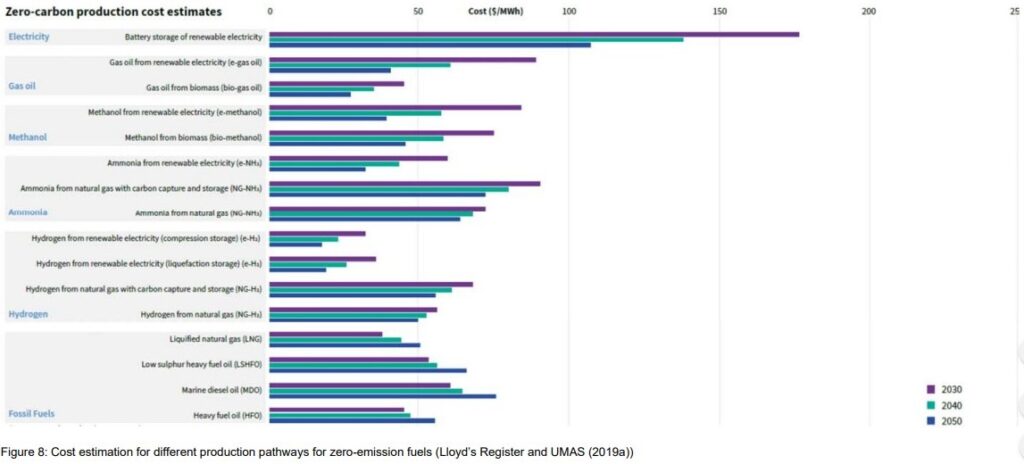

There is one big disadvantage however, which is that methanol is a low flash point fuel, that imposes similar safety handling measures as for LNG. The price development of methanol and other alternative fuel options is uncertain and depends largely on the technical development of different fuel production pathways which in turn affect the environmental performance of the fuel.

Additionally, the paper attempted to identify the methanol demand within the shipping industry. It is anticipated that for almost all vessel types, sailing on methanol will require to bunker more frequently, or have increased bunker capacity onboard.

For the short sea line service, port vessel and pipe laying vessel it was found that the existing tasks can be performed with the existing bunker capacity combined with more frequent bunkering. The yacht requires additional bunker tanks in order to keep trans-Atlantic capability. However, it was assessed that the fuel usage of the vessels calling Dutch ports would allow the usage of methanol. For the smaller vessels travelling over shorter distances, the application of other zero-emission fuels like pure H2, could potentially also be viable.

The report has also identified concrete discrete challenges and knowledge-gaps that should be further addressed within the Green Maritime Methanol Project:

1. Engine technology: Three main technologies have been identified for methanol engines as feasible solutions for shipping on the short term, depending on the emission level and cost target:

- Dual-fuel methanol-diesel used in a compression ignition engine (individually injected per cylinder in the engine).

- Methanol used in a lean-burn spark ignition engine (100% single-fuel);

- Methanol emulsification in diesel used in a compression ignition engine (pre-blended “mono-fuel”).

The dual-fuel principle is currently applied in some vessels, while Tier III compliance has been demonstrated. The technical feasibility of the other two engine technologies needs to be further investigated by means of experimental research on maritime engines.

2. Supply chain: The future development of the different supply chain options remains largely uncertain. Most notably the long term development of biomethanol and synthetic methanol will be assessed as part of WP4, investigating the long term viability and price development; and will be further analysed.

3. Ship Design: Finally, the impact of methanol application on vessel layout has been analysed for a few different vessel types (pilot ships, ferries) in previous projects and the Green Maritime Methanol project will take this further and investigate the impact on five vessel types, providing input on the feasibility of retrofitting existing vessels and newbuild options.

Concluding on the potential of mehtanol as a marine fuel, the report highlights that:

Methanol seems to be a feasible viable alternative fuel option for several maritime market segments sectors based on the current operational profiles and the current fuel storage facilities on board vessels; Nonetheless, there are uncertainties regarding bunkering of methanol in terms of pricing and bunkering options in different ports. As a result, there is a need for a financial and operational business case which will also be included within WP4