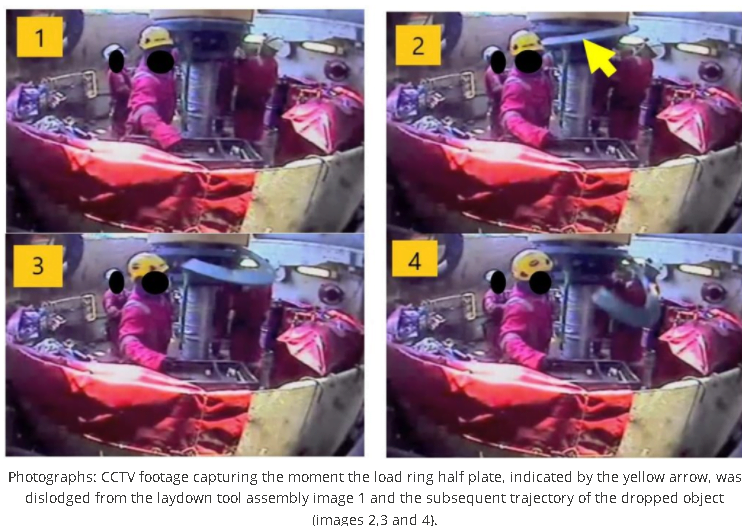

IMCA describes a case where during removal of the anti-rotation/laydown tool from a Flex-Joint, a load-ring half plate, weighing 85kg, was inadvertently dislodged and dropped about 1.8m to deck.

The incident

As informed, crew on a J-Lay Tower were removing the anti-rotation device/laydown. The tower was tilted to 5 degrees at the time of the incident. A team of riggers and technicians proceeded to remove the half plates, which form part of the laydown tool.

After the load ring securing plate was removed and the final jacking bolt had been loosened, one load ring element slid out of the assembly and dropped down onto deck.

There were two persons closed to the dropped half ring. No one was injured during the incident.

What went wrong?

- Procedures not followed:

- The removal of the load ring plates did not follow the approved procedure. The task plan included the manufacturer’s procedure which described the correct way to do it, which required eye bolts and rigging to remove the section of the laydown tool using a crane;

- The task of removing the load ring half plates manually/by hand was deemed to be faster and required less steps than the approved procedure;

- The risk associated with the removal of the heavy load rings by hand instead of using a crane was not assessed.

Lessons learned

- Follow the instructions; keep to the procedures.

- Any planned changes to the task plan or procedure should require a Management of Change process to be conducted to assess the risks from the change, apply the appropriate controls and gain authorization to proceed;

- If unsure of the correct method to execute a task, or the associated risks, personnel should always speak to their supervisor before attempting the task – don’t be afraid to STOP THE JOB.