As UK MAIB reports in its most recent Safety Digest, a large car carrier suffered a fire inside the fuel purifier room while on passage.

The incident

The crew evacuated the engine room, stopped the ventilation and closed the fuel supply to the engines before deploying the carbon dioxide (CO2) fixed firefighting system. The bulkhead temperatures were monitored and the fire was declared successfully extinguished when these had reduced to a safe level. The vessel was left without power as a result of the fire and had to be towed into port for repair.

Subsequent inspection identified that this short but intense fire had caused severe damage to the fuel purifier room, including the purifiers, fuel booster modules, heaters, associated electrical plant and cabinets. The adjacent space deckhead wiring and electrical cabinets in the engine room had also been impaired, albeit to a lesser extent.

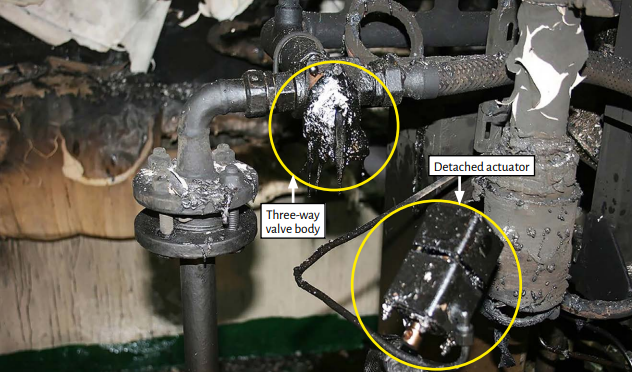

Examination of the equipment indicated that the fire had likely broken out due to gas oil spray emitted from a gas oil purifier system three-way inlet fuel valve actuator. The actuator had become detached from the valve body and the whole assembly was severely damaged by fire and heat. Separation of the actuator and valve actuator spindle from the valve body allowed the fuel, operating at 2 bar pressure, to escape and spray over nearby heating and electrical equipment. On closer examination, the screws that secured the two parts of the actuator to the valve body were found to be slack.

Lessons learned

- Action: The crew’s response to the rapid escalation of the fire prevented further widespread damage and risk to life and, despite being left without power, the vessel was able to be towed to port and eventually repaired. Knowing how to respond effectively to the outbreak of a fire is imperative to avoid potential devastation.

- Observe: Vigilance during engine room rounds mitigates the risk of unwanted breakdowns. However, spotting loose screws on an actuator in a hot purifier space would test many of us. Seemingly insignificant components can have a considerable impact on crew and vessel safety; it is well worth applying a little tender loving care to check that even small parts such as these are correctly fitted and maintained.