As part of its monthly Safety Flashes, IMCA summarizes a case of shackle failure during over-boarding of pennant wire and ballast chain.

The incident

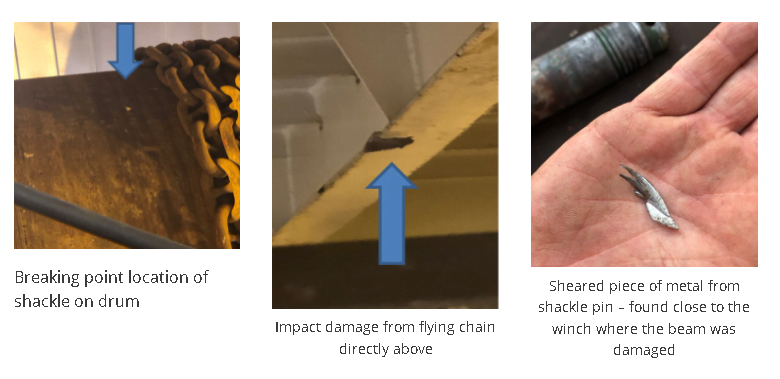

During over-boarding of the pennant wire and ballast chain from the main anchor handling winch over the stern roller, there was a failure in the chain link / 35t shackle.

The failure occurred and the damaged chain came off the winch, went across the main deck and over the stern of the vessel. Everyone was in a safe position, and no-one was harmed, but there was damage to other nearby winch equipment. 110m of chain were lost overboard; our member calculated that this meant there was approximately 31.7t (submerged weight) of tension on the chain at the time of the incident.

What went wrong?

- Evidence suggested that during the over-boarding of the chain, the nut on the shackle pin became lodged behind the stud piece of the chain link whilst wrapped on the winch drum.

- When tension was applied on this section of the chain the links straightened and caused the nut of the shackle to be forced off along with the stud piece.

- The resultant shock may have then forced the pin out of the shackle and allowed the chain to part;

- At the point of shackle failure, the chain on the winch drum become loose and whipped towards the special handing winch causing multiple impact damage to surrounding equipment;

Lessons learned

- Immediate causes

- Connection of different chain link sections using shackles and spooling them off the stern of the vessel for wet storage;

- The decision to wet store the ballast chain was made onboard and not covered in the original project planning or HIRA.

- Underlying causes

- No inspection certificates available for the 82mm chain;

- Poor maintenance of the 82mm chain due to the fact it was only to be used as ballast weight in single 27.5m sections;

- Kenter joining links were not used to connect the section of 82mm chain together, they were ordered but did not arrive;

- Internal signed management of change documentation was missing some important detail regarding the actual connection of the individual chains to be wet stored;

- The chain was connected with 35t shackles which have multiple edges that can be caught or trapped inside other equipment, especially the nuts.

- The assessment of risk of connecting the chains using the shackles was overlooked mainly due to last minute change in the engineering planning of this scope of the project