As UK MAIB reports in its most recent Safety Digest, a tanker was making its final approach to an oil berth with two tugs attached and a pilot on board.

The tanker’s crew had tested the propulsion control system before arrival, during which the main engine was run in both ahead and astern directions without incident. As the tanker drew level with the berth the pilot requested dead slow astern on the main engine to stem the vessel’s speed but, despite numerous attempts, the engine could not be started in the astern direction. Under the direction of the pilot, the tugs were able to arrest the ahead movement of the vessel and successfully berthed the tanker alongside the terminal.

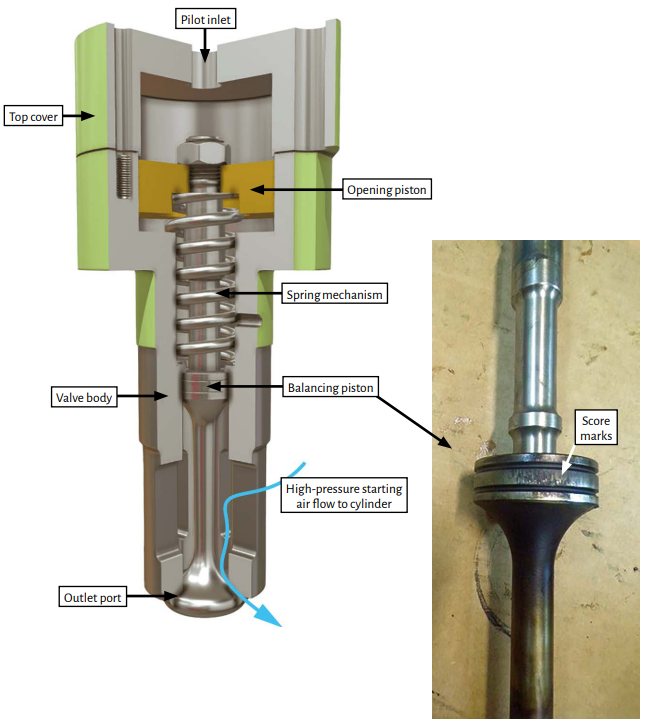

The engine was designed to be started by injecting high-pressure air through an air start valve into each cylinder in turn to start it rotating. The air was shut off once the engine was up to the required speed, then fuel was injected to keep the engine running. To operate astern, the engine was stopped and air was injected into a different sequence of cylinders to turn the engine in the opposite direction.

Tests of the engine starting system showed that the No. 2 cylinder air start valve had seized in the closed position, which prevented air being injected into that cylinder and effectively created a dead zone in the starting sequence. Consequently, the dead zone prevented the engine starting in the astern direction when the crew attempted to manoeuvre the tanker. Disassembly of the air start valve found that cylinder combustion gases had leaked into the body of the air start system and scored the balancing piston, causing it to overheat and seize. The valve was replaced with a spare carried on board, after which the engine was tested and was once more able to run both ahead and astern.

Lessons learned

- Risk → The failure of a single component in the air start system led to a significant hazard for the ship. Such failures can have serious consequences, and it is vital to identify potential hazards and implement measures such as checks and proper maintenance to ensure reliability.

- Hazard → Air start valve leakage presents a considerable risk. While the failure in this case prevented the engine from starting, leakage of hot combustion gases into the air start system introduced the risk of a starting air system explosion. Early detection and remedy is vital to maintain a safe engine room environment and prevent devastating consequences.

- Plan → The well-planned berthing operation meant that tugs were available to assist the tanker. The engine air start system had worked without incident when tested, but later failed unexpectedly; the presence of the two tugs ensured that the loss of astern propulsion was problematic rather than catastrophic.