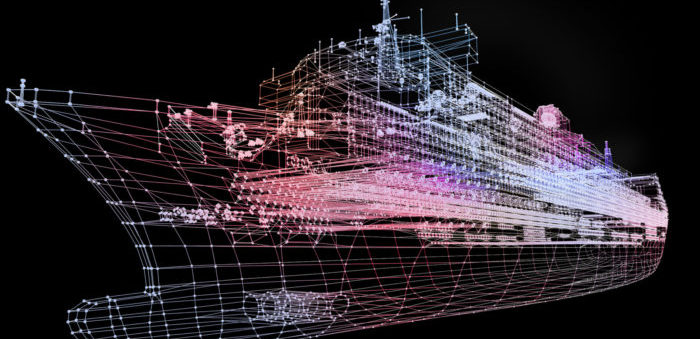

The first commercial U.S. vessel designed, built and verified using an end-to-end 3D design process is now under construction.

The project is a collaboration between ABS, Robert Allan Ltd. (RAL), Signet Maritime Corporation (Signet) and the United States Coast Guard (USCG).

Designed by RAL, the Advanced Rotortug (ART), is designed to escort vessels and offshore assets at the Port of Corpus Christi.

The vessel was designed by a purely 3D process, which is considered to reduce costs and time investment, while streamlining interaction between all stakeholders throughout the design, verification and construction phases, without compromising safety.

This landmark achievement sets the bar for future projects both in the U.S. and internationally. Together with our forward-looking partners, we have realized a long-held dream of the industry to leave behind 2D paper plans and move to the next generation of vessel production … The advantages are significant, and we are confident that once the industry develops the infrastructure to handle 3D models in shipyards, a pure 3D process will become the default approach

said Christopher J. Wiernicki, ABS Chairman, President and CEO.

Moreover, Timothy S. McCallum, Signet Vice President, Engineering and Dynamics, believes that 3D design review ensures the designer, engineer, production manager, fitter, welder, and surveyor all work from the same complete model.

Each individual has access to both the micro (component) and macro (complete assembly) with which they are working to better understand the bracket, frame, or bulkhead as it relates to the module, section, and ship