EMSA has published a report which analyses hydrogen’s main characteristics to frame which safety hazards, system threats and risks to be considered and mitigated when using hydrogen as ship fuel.

The purpose of the report is to assist the industry and the regulators towards a safe and harmonised deployment of this relevant technology that could demonstrate an important step towards decarbonisation of the sector. According to EMSA, hydrogen, when used as ship fuel, presents the following significant safety hazards and risks due to its unique properties:

Flammability and explosiveness

Hydrogen’s wide flammability range and lower ignition energy compared to methane make it highly flammable and prone to more severe explosions. Its higher burning velocity can escalate explosions into detonations, posing greater risks than natural gas.

Storage and distribution challenges

The low boiling point of hydrogen complicates its storage and distribution. Managing boil-off gas and preventing the condensation of gases like nitrogen and oxygen are critical to avoid equipment malfunction and potential explosion hazards.

Density and dispersion

Hydrogen’s low density causes it to rise and disperse quickly in open environments. In confined spaces, such as within a ship, it can accumulate in high spots, increasing the risk of ignition from sources like ceiling lights. Designing safety measures, such as gas detectors and ventilation systems, must account for hydrogen’s density and behavior in leak scenarios.

Pressure effects

High-pressure storage of hydrogen (250-700 bar) creates potential energy that, upon release, can cause significant pressure effects even without combustion. Sudden releases from high-pressure systems can ignite spontaneously, posing immediate risks to personnel and equipment.

Hazards in confined spaces

Hydrogen releases in confined ship spaces amplify explosion pressures rapidly, potentially damaging structures and leading to further leakage. Leakages of liquefied hydrogen (LH2) can induce cooling effects that compromise gas-tight integrity and safety equipment function, further complicating emergency responses.

Material compatibility and embrittlement

Hydrogen can adversely affect metal properties through embrittlement, reducing structural integrity. Condensed oxygen-enriched air can increase material flammability upon contact, necessitating careful material selection and design considerations.

Health and safety risks

Finally, EMSA notes that significant hydrogen leakages pose risks of asphyxiation due to oxygen depletion, alongside risks of frostbites and burn injuries due to low temperatures and reduced flame visibility.

Lessons learned from hydrogen-related accidents:

- Reviewing accident databases shows that hydrogen-related accidents happen. From the 575 accidents analyzed in the HIAD 2.0 database, the leading causes of hydrogen-related accidents fall into two categories: system design error and failure, and human error. A combination of both was also a cause of accidents with severe consequences. The largest number of cases were linked to safety management system factors (49%). The second largest cause was errors in the material or manufacturing (35%). Many of the incidents were caused by individual human errors (29%) and system design errors (27%).

- Nearly half of the incidents in the HIAD 2.0 database were related to human and organizational errors. Therefore, training the operating personnel and increasing their understanding of hydrogen hazards will be crucial to preventing future hydrogen-related incidents. Similarly, the safety management systems must properly account for hydrogen hazards in operating procedures, inspection plans, and emergency response procedures.

- Hydrogen-related accidents are documented in databases such as the HIAD 2.0 database, with 575 accidents analyzed.

- Leading causes of hydrogen-related accidents include system design errors and failure and human errors

- Combinations of system design and human errors often lead to severe consequences in accidents.

- Safety management system factors account for 49% of hydrogen-related incidents.

- Errors in material or manufacturing contribute to 35% of accidents.

- Individual human errors are responsible for 29% of incidents, while system design errors account for 27%.

- Approximately half of the incidents in the HIAD 2.0 database are attributed to human and organizational errors.

- To prevent future hydrogen-related incidents, it is crucial to:

- Provide training to operating personnel on hydrogen hazards.

- Ensure safety management systems effectively address hydrogen hazards in procedures, inspection plans, and emergency response protocols.

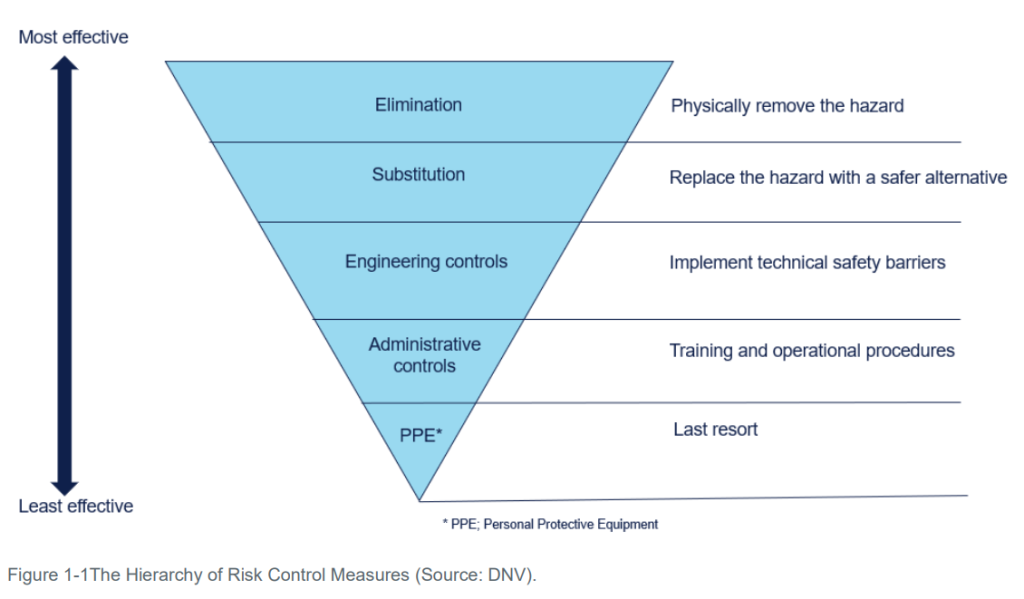

We find that the existing safety barriers in the IGF Code for natural gas do not account for hydrogen’s extreme flammability properties, and the need for further regulatory development is also supported by EMSA (2023) and (DNV, 2022), which identifies many required safeguards for hydrogen not found in the IGF Code.

… EMSA notes