New guidance by DNV on achieving stable lifting operations dives into the key considerations and calculations to help ensure these hazardous operations are performed safely to reduce the risk of loss to life, property and the environment.

The paper has step-by-step guidance for drafting, evaluating, and finalizing rigging plans, focusing on critical factors like centre of gravity, friction-dependent rigging points, and operational limits. Furthermore, it compares stability assessment methods.

Guidance is grouped into five steps

- Step one involves preparing a draft rigging plan.

- Step two is to assess whether the rigging points are friction-dependent.

- Step three is working out if the centre of gravity (CoG) of the rigging arrangement is above the lifting points.

- Step four, if applicable, is determining and documenting operational limits.

- Step five, finalize a stable rigging plan that complies with established safety criteria.

Comparing methods for stability assessments of lifts

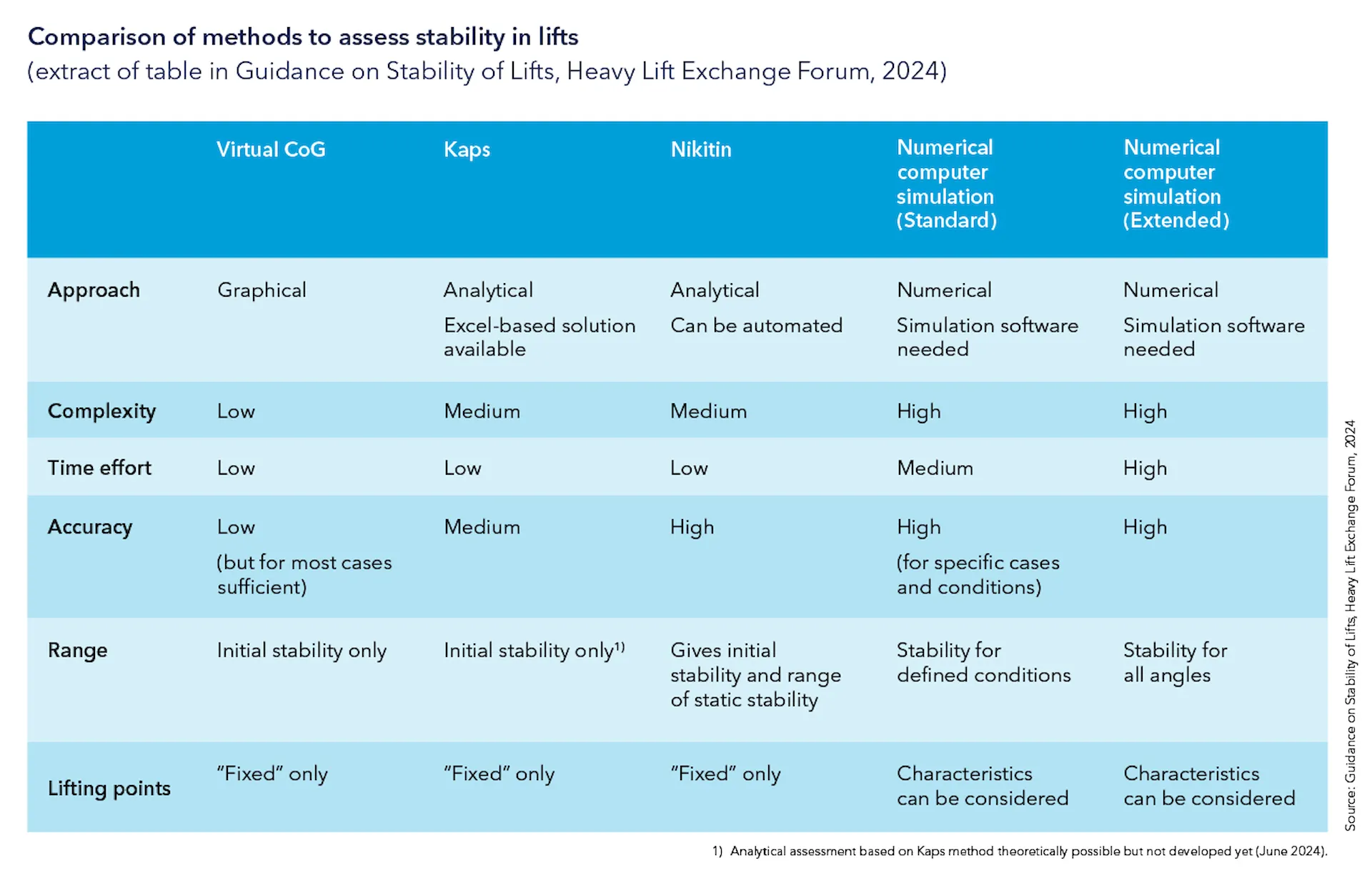

To assist the process, the guidance makes a comprehensive comparison of different methods to assess the stability of lifts.

These methods are the Virtual CoG concept; the Kaps method, which is widely used in the maritime industry; the Nikitin method; and standard and extensive versions of numerical computer simulation methods.

The applicability of these methods for various purposes is discussed. For example, Virtual CoG and Kaps allow users to evaluate the initial stability of the lift, Nikitin provides insight on the stability against the overturning of two-chain suspensions, while numerical computer simulations allow a much more detailed analysis.

What should be considered in the stability assessment?

A stable lift is one that remains in a balanced condition, within a safe margin, when subjected to predefined disturbing factors. Disturbing factors may include wind force, rigging length tolerance, steering line forces, crane movement, CoG shift, vessel motions and friction at the lifting points.

The guidance paper explains several disturbing factors, together with relevant mathematical equations for calculating their impacts. It presents this material in a way that allows these factors to be incorporated into the calculations for rigging stability assessment.

Calculating sliding and effective inclination angles

The sliding angle is the inclination angle at which a lifted cargo starts to slide, and it should never be reached during lifting. The angle depends on the friction between the materials in use, and on the shape of the contact surface. For instance, the effective inclination angle of a belly-slung cylindrical object is significantly different to a conical section.

Calculating sliding and effective inclination angles is useful when assessing lifting arrangements that involve friction-dependent lifting points, which exploit the fact that frictional force resists relative motion between surfaces in contact.