During the 2023 GREEN4SEA Athens Forum, Dr. John Kokarakis, Technical Director Southeast Europe, Black Sea & Adriatic (SEEBA) Zone at Bureau Veritas, noted that ammonia will be more utilized as a carrier of hydrogen in a future hydrogen ecosystem.

Currently, the global fleet requires around 300 million tons of heavy fuel oil. According to the energy ratio, if the entire fleet burned ammonia, it would require 645 million tons of fuel solely for shipping. Given that ammonia is largely utilized in fertilizers, worldwide ammonia production should be four times higher.

Production

Ammonia is produced using the Haber–Bosch method. It’s a very energy-intensive process with high pressure, high temperature, and a need for catalysts. Alternatively, biogenic methods can be used such as ammonia from biochemical production by photosynthesis of cyanobacterium anabaena azollae.

Chemical properties and emissions

Ammonia can be used in a variety of energy converters, including fuel cells, steam and gas turbines, and internal combustion engines. However, it’s a fuel that doesn’t burn easily which means that its combustion needs to be enhanced. This can be achieved by:

- Mixing (doping) ammonia with hydrogen. However, caution needs to be exercised when using this method as hydrogen is explosive, especially in compression ignition engines.

- Swirl stabilization burners

- Stratified combustion

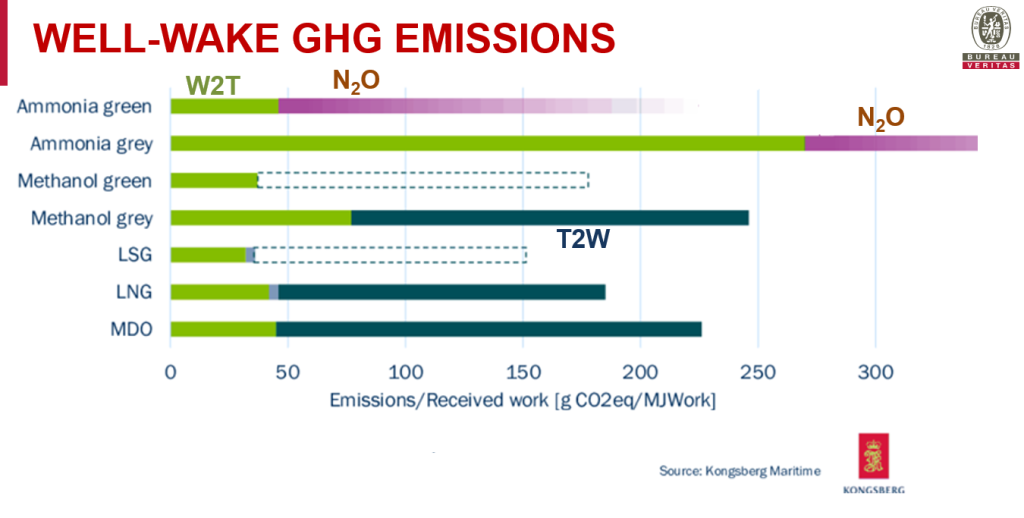

Ammonia doesn’t contain carbon, yet it still needs carbonaceous pilot fuels to burn. The proportion of pilot fuel increases to 30% when applied to the higher-speed four-stroke engines. Ammonia has more CO2 emissions than methanol when we look at well-to-wake emissions when it is produced from fossil fuels. Additionally, its emissions include nitrous oxide (laughing gas), a greenhouse gas that is 300 times more harmful than CO2.

Since ammonia contains nitrogen, NOx will inevitably be present in the exhaust gases. As a result, it is necessary to add abatement equipment like a Selective Catalytic Reactor (SCR). Furthermore, specialized scrubbers with carbenes could be utilized to reduce laughing gas emissions.

Since ammonia contains nitrogen, NOx will inevitably be present in the exhaust gases. As a result, it is necessary to add abatement equipment like a Selective Catalytic Reactor (SCR). Furthermore, specialized scrubbers with carbenes could be utilized to reduce laughing gas emissions.

Design aspects

The design aspects that need to be considered are:

- Risk assessment as there are no prescriptive rules

- Diffusion analysis following leakages. Ammonia is very toxic and thus its use as fuel is forbidden by the IGC code.

- Detection and management of NH3 leakage

- Management of NH3 spillage/vapors

- Control of ammonia discharge to the sea

- Material selection (including elastomers)

- Containment system

- Engines (which are not yet available) and Fuel Supply Systems

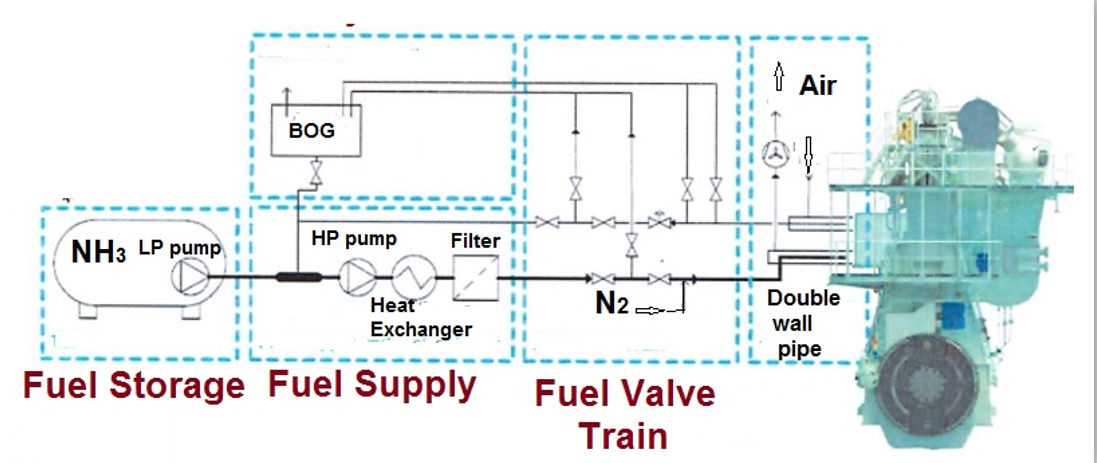

Fuel supply system

Because ammonia and LPG have close thermodynamic relation, an ammonia fuel supply system is highly comparable to that of LPG.

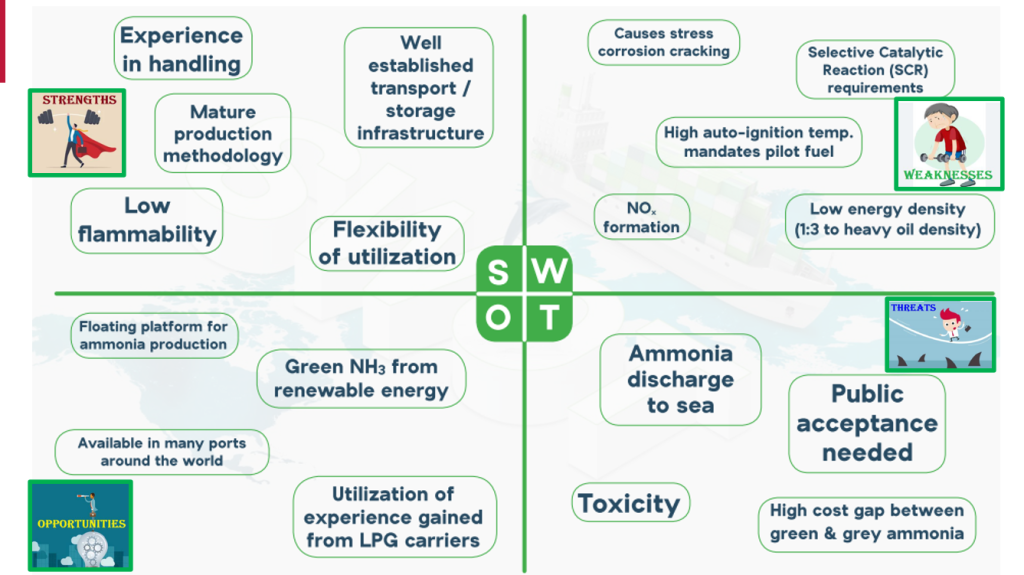

Why use ammonia?

- Ammonia is the best carrier for hydrogen

- There is handling experience because it’s being used as fertilizer

- It’s mildly cryogenic (boiling point equal to -33o degrees Celsius)

- Its energy density is comparable to methanol.

- Its production is mature

- There is a well-established transport and storage infrastructure

- No carbon emissions

- Ammonia can be produced with renewable energy as source of electricity

- Relatively low flammability

- Lower boil-off rate

Why not use ammonia?

- Ammonia is highly toxic.

- It causes stress corrosion cracking to plastics, metals, and elastomers so materials need to be chosen carefully

- Ammonia emits laughing gas

- It has a high solubility in water and high autoignition temperature.

- There is a high-cost gap between green/grey ammonia

- Production must be quadrupled in order to suffice for the fleet

- Bunkering must be developed

- Its production is energy-intensive

- Public acceptance is needed

- IMO IGC Code forbids its use as a fuel

To use ammonia, the crew should be trained adequately in how to handle ammonia safely. Furthermore, currently, ammonia is very expensive. Hopefully, the price will be reduced by the increase in scale. The cost of the required electricity will also affect the price. Yet, using clean, safe nuclear energy can lower electricity bills.

SWOT (Strengths, Weaknesses, Opportunities, and Threats) Analysis

Ammonia’s Pathway to Maturity

As promulgated by the engine makers, ammonia as a fuel will probably reach maturity around 2035. The first step for ammonia to reach maturity is that port production should facilitate transportation. In addition, green hydrogen must be produced from renewable electricity.

In the presenter’s opinion, ammonia is unlikely to become the dominant fuel of the future. It will be present but more as a hydrogen carrier. Hydrogen is the mother of all fuels.

The above article has been edited from Dr. John Kokarakis’ presentation during the 2023 GREEN4SEA Athens Forum.

Explore more by watching his video presentation here below

The views presented are only those of the author and do not necessarily reflect those of SAFETY4SEA and are for information sharing and discussion purposes only.

This is a decent overview, but there are a number of statements I question.

First, it fails to recognize that green ammonia has a much clearer pathway toward price reduction than methanol. The speaker doesn’t seem to propose what will become the dominant fuel instead. I still contend it will be ammonia.

Second, it is incorrect to say the pilot fuels must be carbon based; any low flashpoint fuel can work, including hydrogen (which can be cracked from NH3).

Third, the statement that ammonia will generate NOX because it’s nitrogen based I believe to be misleading. The engine companies have not indicated any issues with NOX, and most N2 for NOX production comes from the air, not the fuel (remember air:fuel ratios are usually around 8:1).

Finally, the engine companies also have indicated they do not see a major issue with N2O.

Many of these assumptions are still yet to be seen, it’s true. But I don’t believe we should draw any conclusions until the engines are operating and demonstrated.

Another issue with these remarks is the statement that “ammonia production requires a lot of energy.” Well of course it does – any clean fuel requires a lot of energy – that’s the point! The fuel has to have a lot of energy embedded in it else it’s not a very good fuel. And when you’re manufacturing a green fuel, all will require a lot of energy to produce.

What is most important is efficiency, and most efficiency losses with green ammonia production are in the electrolyzers that generate hydrogen. This step will be consistent for all forms of green energy, not just ammonia. And that tech is improving rapidly.