The British Tugowners Association (BTA) published guidance in order to explain how does an operator purchase a rope that does the job required of it, what does success look like for the procurement process, and what does an unsuccessful towing system look like.

All too often when a tow rope parts or breaks, the assumed solution is that the rope was not large enough or did not have a high enough Minimum Breaking Load, say the report.

Whilst this may be correct in the occasional occurrence, this is not the right answer in the main. The importance of proper rope selection, handling, inspection, and retirement cannot be overstated

Tow ropes safety

Tow rope certificates vary considerably from manufacturer to manufacturer and between retailers and resellers. Such variety can lead to a lack of clarity and confusion of the rope purchased and not facilitate rope comparison.

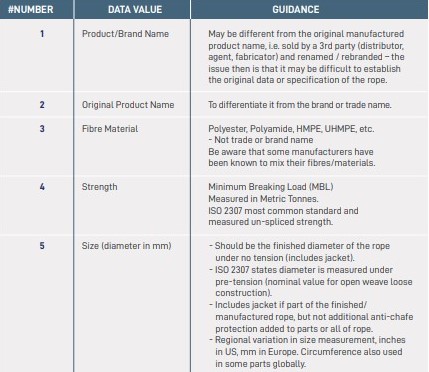

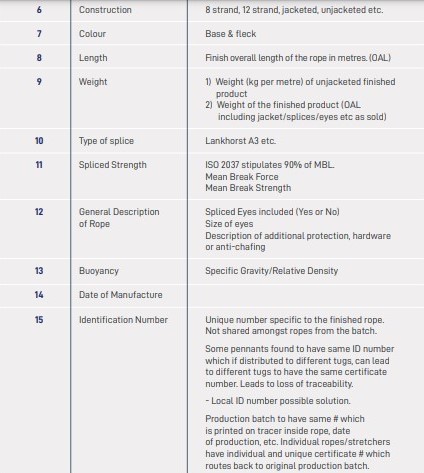

BTA in collaboration with tow rope manufacturers have comprised the following list of data variables which it expects to see on a tow rope certificate. Noting that individual manufacturers wish to retain stylistic control, the BTA suggests harmonisation of tow rope certificates rather than standardisation.

In addition, to ensure appropriate and adequate space for annotations, the BTA recommends the inclusion of a table on the rear of the certificate for such information and signatures.

In fact, rope manufacturers, suppliers and Classification Societies are increasingly providing rope certificates in digital format with the ability to note annotations. However, for the purpose of safety and security, information provided on original certificate should be ‘protected/locked’ by the supplier to prevent amendments to the original characteristics.

Annotations should only be allowed to add notes during the life of the rope, and not amend or delete original information or earlier annotations

Furthemore, record keeping is essential for the safe use of mooring and towing ropes. It is not uncommon for crews to move between vessels and it is very likely that at some point a Master will be asked to perform a tow using a rope they are not familiar with.

When this occurs, it is necessary for the Master to understand the life of that rope, informing their understanding when making their inspections

This information should be readily available and easily linked to the rope it describes. There are many methodologies for maintaining this information. Some operators mark their certificates, some keep an online log, some maintain a rope register.

As well as keeping readily accessible records of a ropes life it is necessary to be able to easily link those records to the specific rope they refer to. “Keeping track of the colourings of the rope may not be enough.”

Moreover, rigid identification tags can sometimes be found in use. These bring with them concerns of damage to the rope should they become caught between the rope and some part of the assisted vessel or tug. They are also highly susceptible to being damaged themselves and thus becoming lost.

Whichever method of identifying ropes is put into practice, the ropes in use, and in storage, should be clearly identifiable with their characteristics and life easily traceable

highlights BTA.