USCG issued a Safety Alert addressing the importance of verifying the condition and manufacturing of wire rope terminations used in various systems that utilize wire rope in a load-handling capacity (e.g., lifesaving appliances, cranes, lifting slings).

As explained, the Coast Guard is currently investigating a casualty involving a failed wire rope termination that resulted in extensive damage to equipment.

Namely, USCG observed that “improperly applied swaged fittings could result in unintentional damage to the wire rope, resulting in failure of the termination. Improper swaging procedure includes failures within a quality management system in which materials are improperly selected and do not match the specifications of the original equipment manufacturer”.

The USCG also made the separate observation that “different types of fittings/end terminations might decrease the safe working load (SWL) of the wire rope. With this in mind, the type of fitting could affect the safety factor that is required by regulation or recommended by industry standard/practice for the application (e.g., 6:1 for lifesaving appliances launched with wire rope falls). As an example, a swaged sleeve in a common turnback eye results in a 90% or better efficiency of the termination (i.e., 10% or less reduction in the SWL of the wire rope) when properly installed in accordance with manufacturer’s recommendations.”

In light of the above, the Coast Guard strongly recommends that owners, manufacturers, operators and service providers utilizing wire rope in systems on any vessel or OCS facility:

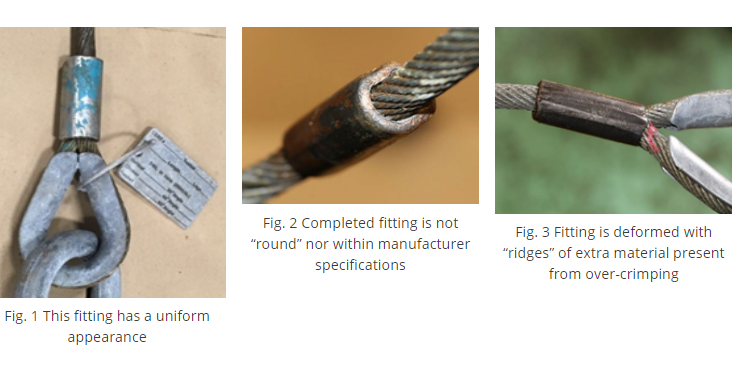

- Visually examine wire rope terminations for abnormalities that may indicate improper installation (Figure 1 shows a crimp with a uniform appearance, Figure 2 shows out-of-roundness, and Figure 3 shows ridges created by over-crimping);

- Compare fitting dimensions against the manufacturer’s specifications/tolerances for the completed fitting (i.e., does the length and diameter fall within fitting manufacturer specifications);

- Verify through documentation related to the manufacturing of the assembly that the materials were properly selected and that the termination type does not reduce the SWL of the wire rope below the minimum safety factor for the type of service.

Concluding, ,arine inspectors, investigators, surveyors and servicing technicians are encouraged to maintain an acute awareness to these issues and initiate corrective actions as needed.