Bunker Mass Flow Metering (MFM) in the Port of Singapore has the potential to reap annual savings of between S$80 million (USD58 million) and S$199 million (USD146 million) for the bunkering industry, a new study shows.

These are the key findings from a case study initiated by SDO@SCIC, on behalf of Enterprise Singapore and the Singapore Standards Council.

Cost savings for bunkering operations account for an estimated 66% to 76% of total savings. Cost savings from the reduction in the number of dispute resolutions as well as the time taken to resolve these resolutions account for the remainder, the study reveals.

MFM is used in Singapore’s bunkering industry for the delivery of marine fuel oil (MFO) in accordance with Technical Reference 48 : 2015. MPA Singapore has required the adherence to TR 48 since June 2016.

MFM is used in Singapore’s bunkering industry for the delivery of marine fuel oil (MFO) in accordance with Technical Reference 48 : 2015. MPA Singapore has required the adherence to TR 48 since June 2016.

Several bunker suppliers surveyed observed enhanced bunker schedule management due to faster and more predictable turnaround in bunkering transactions. A number of shipowners added that inventory management had improved with the increased certainty in the quantity of bunkers received.

They highlighted that the transparency arising from MPA’s strict implementation of TR 48 has increased their preference to purchase bunkers in Singapore.

TR 48 has since been upgraded to a Singapore Standard, SS 648, which includes new requirements for distillate fuels and bunkers to meet IMO regulations. TR 48 and SS 648 have since formed the basis for the development of two ISO standards on bunkering.

Led by Singapore, ISO 21562: Bunker Fuel Mass Flow Meters on Receiving Vessel – Requirements was published in July this year. ISO 22192: Bunkering of Marine Fuel Using the Coriolis Mass Flow Meter System is expected to be published by end of the year.

Meanwhile, to enhance quality assurance and confidence in the bunker supply chain, two new standards have been developed:

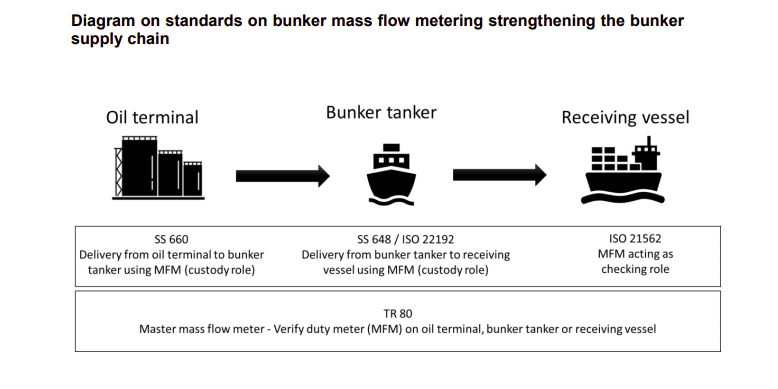

- Singapore Standard 660 : 2020 (SS 660) covers the upstream process for bunker cargo delivery from the oil terminal to the bunker tanker.

- Technical Reference 80 : 2020 (TR 80) reflects the criteria and metrological requirements for a master meter as well as the requirements for duty mass flow meters used across the entire bunker supply chain.

SS 660 includes the quantity measurement requirements during bunker cargo delivery from an oil terminal to a bunker tanker using the Coriolis MFM system. It aims to harmonise the quantity measurement methods at oil terminals and bunker tankers for better accuracy and inventory management. SS 660 also covers quality requirements, which specify taking a representative fuel sample at the custody transfer point to determine compliance with the agreed fuel specifications to assure the bunker quality delivered to bunker suppliers.

With the completion of SS 660 and TR 80, and the recent launch of SS 648, the Technical Committee for Bunkering completes a trinity of bunkering standards covering the local bunker supply chain. These two new standards are also envisioned to be new additions to ISO MFM bunkering standards that are led by Singapore, contributing to the betterment of the global bunkering environment for international shipping,

…noted Mr Seah Khen Hee, Chairman, Technical Committee for Bunkering.

TR 80 reflects the requirements and procedures for meter verification using a master MFM to verify and check the stability and performance of a duty meter installed on a bunker tanker or at an oil terminal. The master MFM is qualified for measuring performance that is three times better than a duty meter and the meter verification process is performed by an independent authorised party for integrity purposes.

Standards assure the integrity of value chains by harmonising technical terms, measures and industry benchmarks, and provide transparency and stakeholders’ accountability. They have contributed to the digitisation efforts of the bunkering industry and strengthened Singapore’s position as a trusted bunkering hub,

…said Ms Choy Sauw Kook, Director-General (Quality & Excellence), Enterprise Singapore.