The Transport Accident Investigation Commission has published a new report regarding the loss of person which fell overboard the Containership Madinah at Lyttelton Harbour entrance on 2 July 2015.

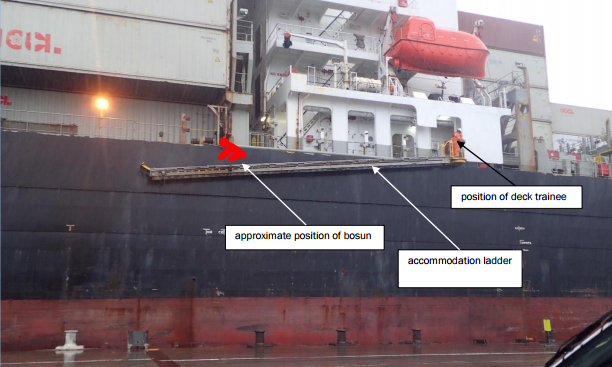

On 2 July 2015 the container ship Madinah was preparing for arrival at the port of Lyttelton. Part of those preparations involved the bosun (deck crew foreman) and a deck trainee rigging the port-side accommodation ladder over the ship’s side in readiness for the ship’s docking.

Both the bosun and the deck trainee were wearing safety harnesses. The bosun sent the deck trainee to fetch buoyancy vests, which were required to be worn for any task outside the ship’s railing. When the trainee returned the bosun had already swung the accommodation ladder over the side, clipped his safety harness to a plastic-coated wire and walked along the accommodation ladder to try to lift the handrails into place.

In doing so the bosun lost his balance and fell into the sea. The wire to which he had clipped his safety harness had broken. A crew member on the deck threw a lifebuoy into the water near the bosun. The bosun was last seen swimming towards the lifebuoy.

The pilot launch that was heading towards the Madinah at the time arrived in the area and started the search. Despite an extensive search using several other small craft and a helicopter for the next two hours, the bosun was never found.

The Transport Accident Investigation Commission (Commission) found that if the bosun had been wearing a buoyancy vest his chances of surviving would have been significantly greater. It also found that the wire rope to which the bosun had connected his safety harness broke because it was severely corroded and also that it had not been constructed and installed in accordance with best industry practice.

Two safety issues identified were: there was no dedicated formal procedure for rigging the accommodation ladders and gangways on board; and although the procedures on board for responding to a man overboard met industry best practice, the shipboard response to the emergency did not follow those procedures.

A third safety issue identified was the use of plastic-coated wire for safety-critical applications. If the plastic coating becomes damaged, salt water can enter and become entrapped in the coating, which causes accelerated corrosion. The plastic coating makes it virtually impossible for the wire to be inspected or surveyed properly. The Commission has raised this issue in a previous inquiry and made recommendations to the Director of Maritime New Zealand to address the issue.

The vessel’s manager has taken safety action to address other safety issues discussed later in the report. Therefore, the Commission has not made any new recommendations arising from this inquiry.

Lessons Learned:

– where it is necessary for a crew member to work over the side of a ship when at sea, they must wear a safety harness attached to a designated strong point and must wear a buoyancy vest

– plastic-coated wires must be treated with caution. Seafarers and surveyors alike must not make assumptions about the condition of any wire that they cannot see, especially when the wire has a safety-critical purpose and is required by rules, regulations or procedures to be examined thoroughly

– a man-overboard situation requires timely and intuitive actions by the crew in order for the rescue to be successful. Crew should follow quick-reference checklists to ensure that: the alarm is raised in the appropriate way; the position of the casualty is recorded and tracked; and the ship is returned to the casualty in the most expeditious way.

Explore more about the incident by reading the report below

Source & Image credit: TAIC