As UK MAIB reports in its most recent Safety Digest, the master and crew of a high-speed passenger ferry had prepared for the day’s scheduled runs. Shortly after starting the ferry’s engines, and on the first run of the morning, the starboard engine space fire detection system alarm activated.

The incident

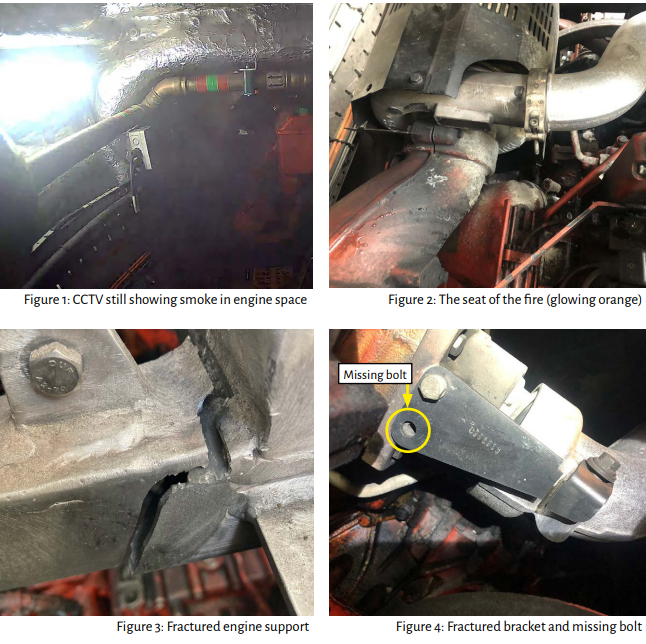

The master slowed the ferry and checked the engine space CCTV but could see no signs of smoke or flames. The detection system was reset and the master increased the speed of the ferry and continued on passage. A while later, the starboard engine space fire detection system alarm activated again. The master again slowed the ferry, checked the CCTV and could see no indication that anything was wrong. The fire alarm system was reset, and the ferry continued on passage. After a third occurrence, the master requested an engineer to check the fire detection system. The engineer found nothing wrong with the system and reported there must be an intermittent fault with the starboard engine space fire detection system.

In response, the master isolated the starboard engine space fire detection system and resumed the day’s scheduled runs. Later, the master observed smoke and flames in the starboard engine space on the CCTV and immediately shut the starboard engine down and instructed crew to close the ventilation flaps for the area. The master then activated the fixed fre-extinguishing system, raised the alarm with the port’s harbour master and brought the ferry alongside the nearest berth, manoeuvring on one engine. Once alongside, the passengers were disembarked and the master was met by the local fire brigade. There was no sign that the fire in the starboard engine space had escalated and the engine space remained sealed.

After some time, the engine space’s CCTV indicated that the smoke had cleared and the external temperature of the space had returned to ambient. One of the hatches to the space was carefully opened and it was confirmed that the fire had been extinguished. The ferry’s engineers found scorched lagging around the main engine turbocharger, along with signs that paint and oily debris had ignited on the engine. This happened because the exhaust inlet casing to the turbocharger had fractured, allowing hot exhaust gases to encroach

the lagging and the engine.

The turbocharger inlet had become fractured by excessive movement of the engine on its mounts. This had happened over time because the engine’s fixed stays and some support brackets had sheared off through vibration and stress.

Credit: UK MAIB

Lessons learned

- Check → Fire detector alarms activate for a reason – never assume it is a fault. Fire detection systems are designed to be reliable and fault-free and most will have a self-diagnosis and fault alert built into the system to differentiate between a fire detector head alarm and a system fault. In this case, the fire detector head had activated due to the release of hot exhaust gases from the engine and initial scorching of the lagging. This happened before the signs of the fire were visible on CCTV and after the system had been isolated. It was fortunate that the master spotted the fire on the CCTV in good time and took correct action to extinguish it and keep crew and passengers safe.

- Maintain → A thorough inspection of an engine during routine maintenance is essential for its safe operation. Check fittings are secure and fit for purpose, replace missing components and report, repair or replace fractured engine supports or brackets before further damage occurs.

- Action → The swift and measured response by the master prevented the fire escalating and causing serious damage to the starboard engine space. The risk of the fire being reignited was also removed by the master’s prompt actions to activate the fixed frefghting system after closing the ventilation flaps and keep the space secured until the fire had been extinguished and the boundary temperature reduced to a safe level.