As UK MAIB reports in its most recent Safety Digest, on a dark, blustery winter’s morning a harbour ferry was leaving its overnight berth, where it had been secured using fixed length, double-eyed mooring ropes.

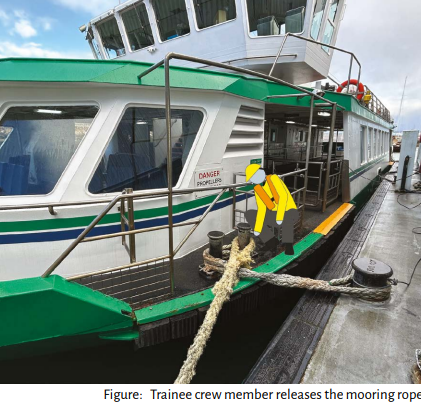

In preparation for getting underway, the ferry’s master used the engines to move the vessel ahead to release the tension on the forward mooring rope. The master assessed that there was sufficient slack in the mooring rope and, once satisfied, gave the order for the trainee crew member to let go the on board end of the rope.

The vessel surged astern as the crew member was lifting the eye clear and their hand was trapped between the rope and the bollard, crushing one of their fingers. The ferry’s crew quickly raised the alarm and the master regained control of the vessel, which allowed the crew member to release their hand. The casualty was taken to hospital for treatment and subsequently was signed off work for several weeks.

Credit: UK MAIB

Lessons learned

- Plan → Plenty of slack must be applied to the mooring rope before crew attempt to remove it from the bollard. Unfortunately, the weather conditions in this case caused the vessel to surge astern, tightening the rope and trapping the crew member’s fingers between the rope and the bollard. A rope pennant fitted to the mooring eye would have removed the need for the crew member to place their hand in danger during this routine, but high‑risk, evolution.

- Communicate → The injured crew member was able to quickly release their hand and received prompt medical treatment thanks to the ferry crew’s efficient response to the emergency and their effective actions.