In its latest Safety Digest, UK MAIB provides lessons learned from an incident where a live fish carrier lost propulsion because of a gearbox failure, resulting in the vessel laying beam on to the sea and rolling heavily.

The incident

It was a poor night with high winds and rough seas when a live fish carrier lost propulsion due to a gearbox failure. Without propulsion, the vessel lay beam on to the sea and began to roll heavily, making life extremely uncomfortable for the four crew on board. The vessel was less than 2 nautical miles (nm) from land and was being blown quickly onshore by the prevailing wind.

[smlsubform prepend=”GET THE SAFETY4SEA IN YOUR INBOX!” showname=false emailtxt=”” emailholder=”Enter your email address” showsubmit=true submittxt=”Submit” jsthanks=false thankyou=”Thank you for subscribing to our mailing list”]

The master of the stricken vessel raised a VHF distress transmission. Fortunately, another fish carrier heard the distress call and was near enough to get a towline onto the drifting vessel before it grounded on the rocky shoreline. A little later, a lifeboat and emergency towing vessel arrived and accompanied both vessels to a safe harbour.

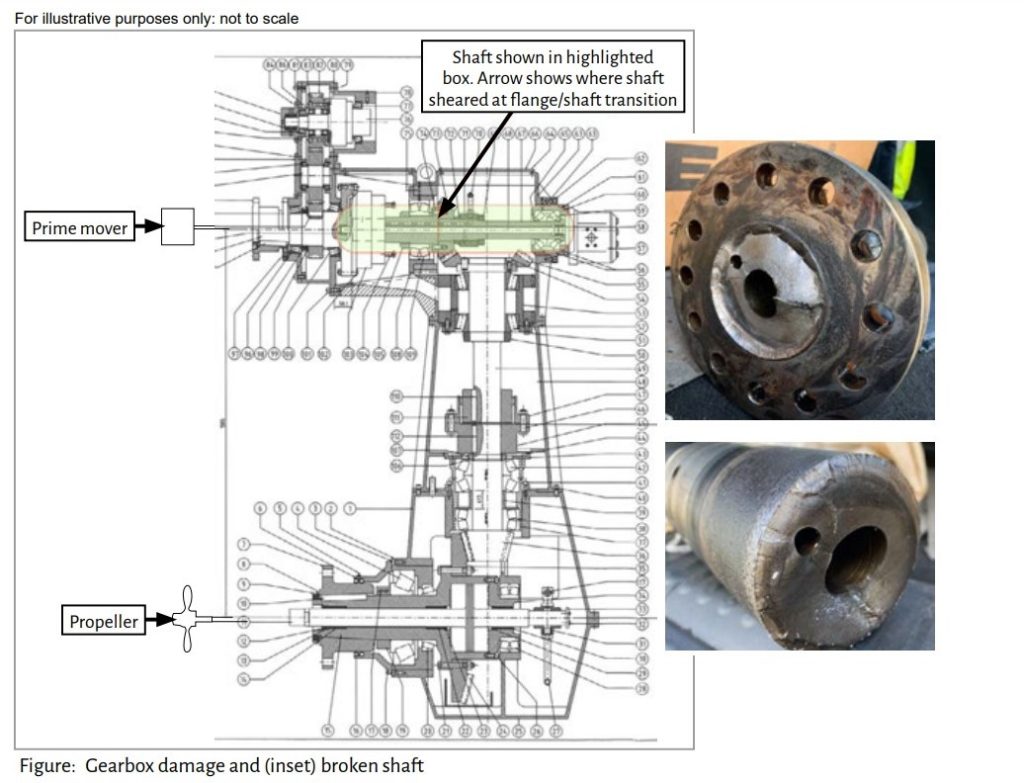

An inspection the following day found that the main input shaft along the top half of the gearbox had failed. The damaged parts were dismantled and dispatched to the gearbox manufacturer who established that the most likely cause of failure was fretting (micro movement) between the gearwheel and shaft, which introduced a crack to the area and resulted in failure. Examination revealed that the failure occurred where the shaft transitioned to the flange for the gearwheel. The vessel was out of service for nearly a month while a new shaft was fabricated and fitted.

Lessons learned

#1 Maintain: The vessel had a history of propeller fouling and minor groundings. The controllable pitch propeller had developed a malfunction, during which the response was erratic and jerky.

- Intermittent problems with propulsion should not be left unattended. Defective propulsion could lead to navigational accidents if vessel control is erratic, especially in shallow and busy waterways.

- Events that stress the propeller can cause significant loading on the driving gear, resulting in relative movement between gearwheel and shaft. Failure is almost inevitable when a crack develops

#2 Check: Since its delivery in 1996, the manufacturer had not serviced or inspected the vessel’s gearbox. Routine inspections and regular gearbox oil analysis were not conducted.

- The gearbox is a complex item of machinery. It needs routine inspection and frequent monitoring to ensure that incipient failures are detected early and corrective actions taken. Regular gearbox oil analysis can be used to detect particles, and therefore provide an early indication of excessive or uneven wear on the components.