A recent IMCA Safety Flash focuses on an incident in which, there was a small fire in the engine room on a vessel in port, to provide lessons learned.

The incident

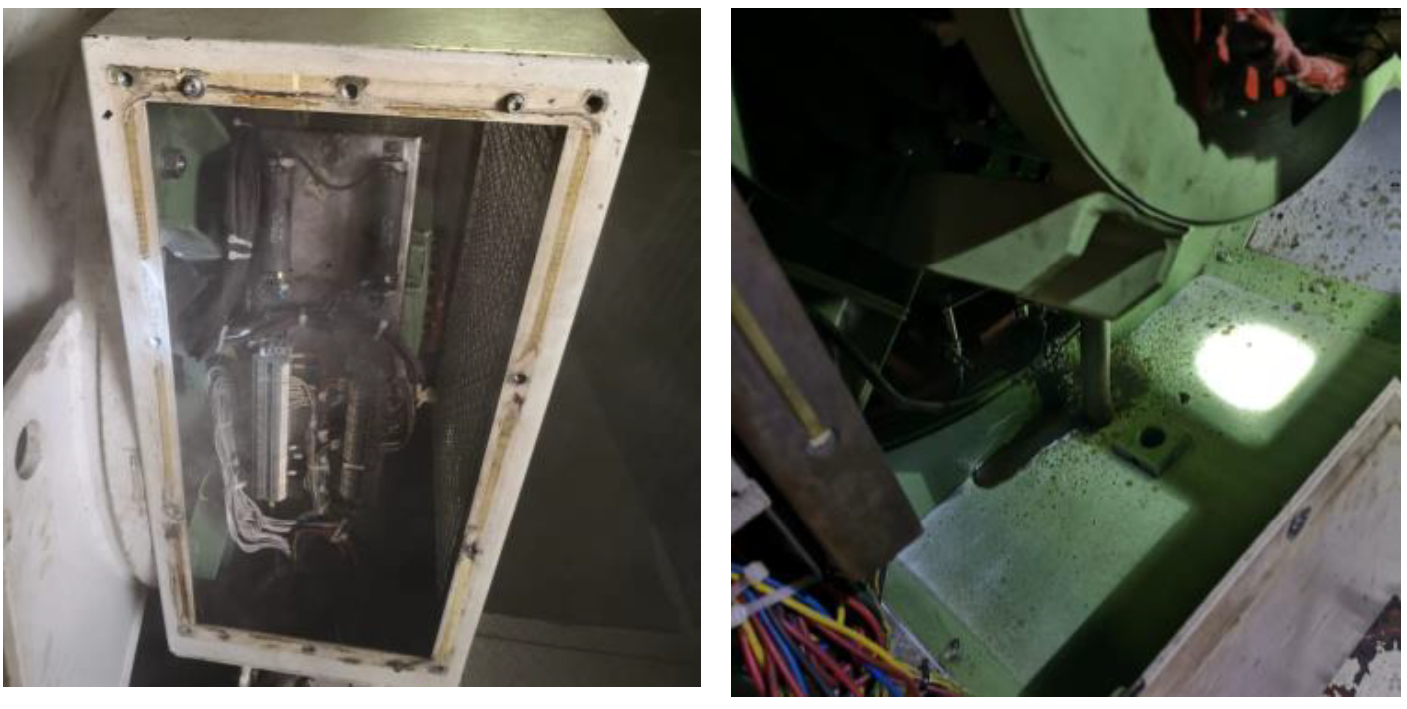

The incident occurred when a diesel generator was being maintained by a third-party maintenance team. On completion of a change of alternator bearings, the generator was tested at idling speed, and no problem was found. But when the generator was tested at operational speed, after a few minutes fire came out of the non drive end exciters. The alarm was raised; the diesel generator was brought to an emergency stop and the fire was put out with an extinguisher.

What went wrong

There was a misalignment of the internal cover of the non drive end bearing. This misalignment caused friction against the shaft and subsequent sparking. The root cause was considered to be insufficient supervision of the third-party personnel conducting the maintenance.

Lessons learned

- Whilst there was only a burnt alternator in this case, the potential was for the fire to have spread throughout the engine room;

- Ensure full and thorough supervision of the personnel of third-party contractors;

- Check carefully the status and readiness of any equipment after maintenance and test – in this case, it was as well that they tested it at operational speed rather than only when idling.