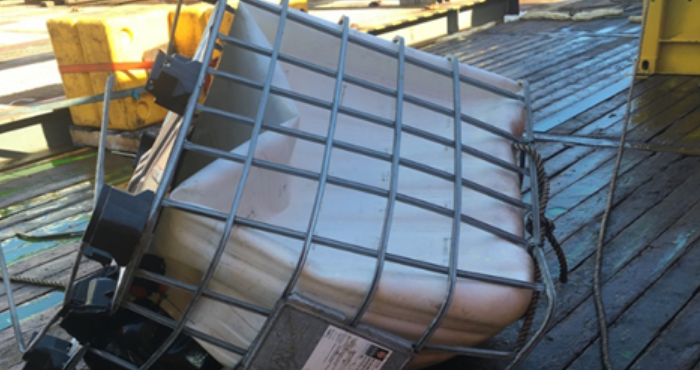

IMCA reported an incident where an intermediate bulk container (IBC) was dropped from a crane to deck. The incident happened when a vessel crane was being used with a certified lifting device to lift and move an IBC containing 1000kg of monoethylene glycol.

The incident

As the IBC was moved, the liquid inside was knocked around which changed the centre of gravity. This caused the IBC to rotate, making the lift rigging device unable to support the load. As a result, the IBC fell about 3.5 metres to the deck and burst open, spilling the contents. The spill was contained onboard with no pollution to the environment.

[smlsubform prepend=”GET THE SAFETY4SEA IN YOUR INBOX!” showname=false emailtxt=”” emailholder=”Enter your email address” showsubmit=true submittxt=”Submit” jsthanks=false thankyou=”Thank you for subscribing to our mailing list”]

Probable cause

IMCA’s investigation is ongoing, but the current cause analysis determined the following:

- Inappropriate risk assessment of the lift;

- Inappropriate selection of rigging arrangement;

- Inappropriate design of storage equipment/containers for liquids which require movement in the offshore environment.

Moreover, there was not enough risk assessment of the effects of the possible combination of:

- The free surface effect in the liquid within the IBC;

- Vessel movement in sea states;

- Crane movement.

Recommendations

After the incident, IMCA proposed the following:

- Review and re-assess the selection and use of liquid storage containers;

- Review and re-assess the lifting and rigging arrangements in accordance to identified international standards;

- Lift plans and associated risk assessments should include not only lifting and rigging arrangements but also possible movement of loads within storage containers which may affect centre of gravity.

In addition, it informed that its member prohibited the lifting of IBC’s utilising pallet type rigging arrangements, and arranged to transfer all IBCs into appropriately designed and certified lifting frames.