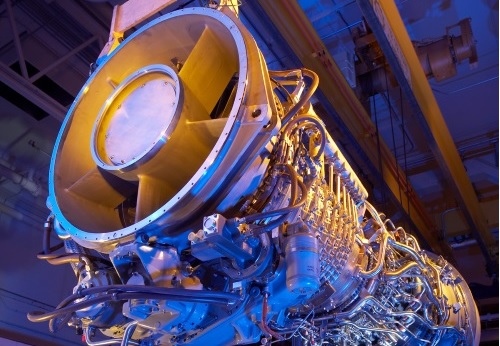

GE’s Marine Solutions now offers electric start systems for its line of aeroderivative marine gas turbines. Along with lower life cycle costs and improved reliability, military and commercial marine customers will enjoy 60% less in acquisition costs with GE’s electric start system compared to a hydraulic start system, the company says.

GE scaled the electric start system technology to match the requirements for its popular LM2500, LM2500+ and LM2500+G4 engines.

“Our LM2500+G4 gas turbines – the most power dense marine module in the world – were selected for the Italian Navy’s new Pattugliatori Polivalenti d’Altura or PPA multipurpose offshore patrol ships. This will be the first use of GE’s electric start system for the LM2500-engine family,” said Brien Bolsinger, GE’s Vice President, General Manager, Marine Operations.

“Benefits with our electric start system include an 82% decrease in footprint and an 85% reduction in weight compared to a hydraulic start system.”

The initial application of GE’s electric start system is on the LM500 gas turbines that power the Republic of Korea’s PKX-B patrol boats. GE’s LM6000PC and LM6000PG gas turbines also are available with an electric start system.

Such a system includes an integrated clutch design included with the module. The electric start system requires only a single cooling interface on the module with the option for either fresh water or mineral oil cooling mediums. The system features the same functionality as other starters including: Engine start; Motoring/purge; Water wash; Borescope

The electric start system for GE’s marine gas turbines is being designed to meet ABS Naval Vessel Rules certification for the United States Navy, specifically for shock, vibration and electromagnetic interference. For the Italian Navy PPA ship, GE is certifying to RINA Naval Rules.

Source & Image Credit: General Electric