Global Centre for Maritime Decarbonisation (GCMD) has published to tackle the absence of an evidence-based tool to detect potential fraud in sustainable Fatty Acid Methyl Esters (FAME) supply chains.

According to the “Rapid Forensic Analysis of FAME Based Biofuels” report, FAME fingerprinting has proven effective in identifying feedstock origins and detecting foreign fatty acid contamination in the marine fuels supply chain. It can also differentiate between virgin or waste-derived FAME from the same feedstock, with the latter having undergone processing, such as repeated heating. However, the process of differentiating processed FAME can benefit from additional data supplementation.

Currently, the approach to determine whether FAME has been processed relies primarily on quantifying linolenic acid content. To advance this finding, it is recommended to gather additional data to establish a quantitative threshold of linolenic acid for definitive distinction between virgin and used palm oils.

Another area meriting future development is the differentiation between FAME produced from palm oil mill effluent and that produced from virgin palm oil, as they share identical FAME fingerprints. One potential approach involves analysing the presence of heavy metals, particularly iron and zinc.

Beyond FAME fingerprinting, work can be done to identify the presence of other unique components, such as dihydroxylpropyl elaidate, i-Propyl 14-methyl-pentadecanoate, and Cis-9-Hexadecenal.

By systematically identifying all these differentiating components, a robust and comprehensive database can be built, enabling FAME fingerprinting to be a reliable tool for providing transparency and preventing fraudulent practices in the supply chain.

As different fatty acid compositions within FAME can significantly impact fuel properties, the ability to fingerprint presents an opportunity to reverse engineer FAME blends with desired characteristics, such as cold flow properties and oxidative stability, specific to vessel performance.

Challenges in detecting fraud in sustainable FAME within marine fuel supply chains

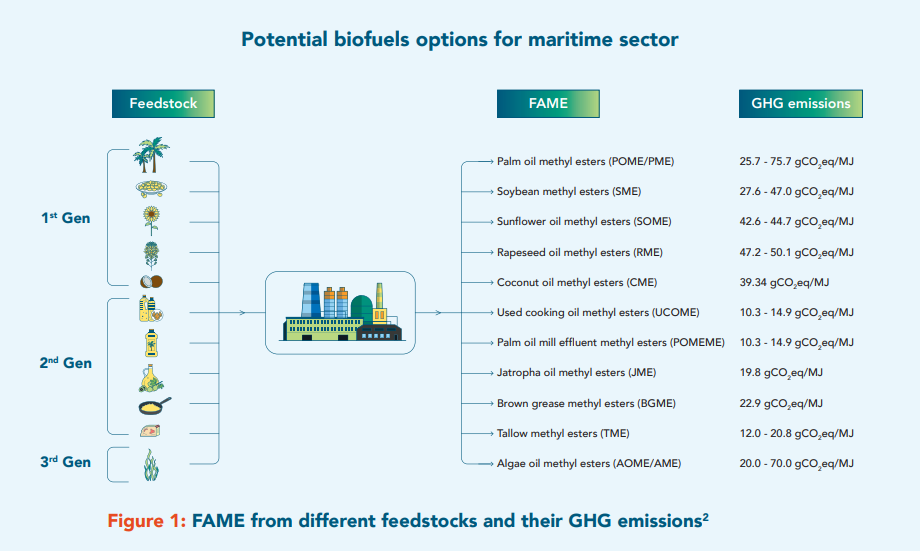

- The legitimacy of FAME as a sustainable fuel is of increasing concern due to a surge in mislabelled FAME products in the market. These FAME products are often produced with less sustainable feedstocks than declared.

- While existing international certification schemes play a fundamental role in certifying sustainable biofuels, their primary reliance on retrospective audits may limit their ability to prevent fraudulent practices, especially in real-time detection of fraud.

- Physical validation complements existing certification practices by providing transparency, justifying biofuels’ green premium, and safeguarding the integrity of marine fuel supply chains.

FAME fingerprinting as a potential forensic tool

- FAME fingerprinting is based on the principle that the fatty acid profile of FAME is unique to its feedstock and can be preserved during feedstock transesterification. The unique chemical signature, or “fingerprint,” of FAME can be compared against a database of known fatty acid profiles to identify the feedstock origin.

- To address the lack of an established method, GCMD and VPS co-developed an analytical method based on EN 14103 to facilitate the acquisition of FAME fingerprints.

- FAME fingerprinting can be performed using a gas chromatograph with flame-ionisation detection, an instrument commonly found in fuel test laboratories.

- The process takes approximately an hour, comparable to the turnaround time for marine fuel quality testing in present-day supply chains, and can be implemented in parallel.

- FAME fingerprinting can enhance visibility, enabling the traceability of feedstock origins in marine fuel supply chains.

Enhancing differentiation between FAME sourced from virgin and waste sources

- Along with specific chemical by-products, FAME fingerprinting has shown promise as a tool to differentiate between FAME produced from the same parent feedstock, such as palm oil derivatives (virgin palm oils, used palm oils, and palm oil mill effluent).

- Further development and additional data are needed to specify the threshold of linolenic acid for definitive differentiation between virgin and used palm oils.

Further work required for greater resolution

- Additional work is necessary to establish higher resolution differentiation based on feedstock origin.

- Specific focus should be on identifying changes occurring during extended heating, such as tracking the formation and evolution of byproducts like linolenic acid and dihydroxylpropyl elaidate. For FAME produced from palm oil mill effluent, heavy metals like iron and zinc can serve as indicators.

- Another area of study is the quantitative relationship between fatty acid composition and fuel properties to help vessel operators optimise biofuel handling and storage practices, mitigating equipment or performance risks.