The Shanghai Maritime Safety Agency has announced the launch of a 3-month Concentrated Inspection Campaign (CIC) on propulsion and auxiliary machinery, commencing from 15 March 2021 and ending on 15 June 2021.

The main objectives of this CIC are to ensure that ships and shipping companies fulfill their non-delegable responsibility for the safety of operation, improve skills of master and crew of the ship for safety and emergency operation the steering gear, propulsion and auxiliary machinery and minimize the loss of lives and property arising from related accidents. In that regard, SQEMARINE provides guidance based on information and data received from the RISK4SEA platform for Shanghai Port and related Propulsion and Auxiliary Machinery deficiencies.

RISK4SEA is an online platform to provide PSC performance transparency to the market by analysing PSC Data providing KPI, Demographics, Detentions Analytics, reports, Benchmarks and Insights for 23 fleet segments in an advanced analysis of the last 5 years to assist stakeholders to:

• PREPARE for forthcoming PSC inspections

• ANALYSE PSC performance to identify strengths & weaknesses

• BENCHMARK fleets against competition and the industry

There are 23 fleet segments and special bundles covered in the advanced data analytics:

Dry Bulk (4) : Handysize, Handymax, Panamax, Cape

Tankers (5) : Product, Panamax, Aframax, Suezmax. VLCC

Containers (3) : Small, Medium/Large, Ultra Large

Other Types (7) : LNG/Gas Carriers, LPG carrier, General Cargo, Vehicle Carrier, Ro Pax, Offshore, Other

Special Bundles (4) : All Dry Bulk, All Tankers, All Containers, All Ships

Explore more at https://risk4sea.com/

Shanghai MSA Guidance

Shanghai MSA made it clear that a ship which suffers a malfunction of forgoing machinery and poses a hazard to the safety of navigation will be subject to a thorough administrative investigation as well as PSC/FSC inspection. It is advised that serious deficiencies will give rise to detention.

Port/Flag State Control Officers (PSCOs /FSCOs) will carry out detailed inspections to verify critical areas for the steering gear, main propulsion machinery, generator, the emergency source of electrical power and its alarm systems, crew familiarization and operational controls.

CIC Checklist

Unlike related CIC launched by several MOUs last year, PSCOs/FSCOs will not apply a questionnaire listing a number of items to be covered during the CIC, but instead they will use a Checklist issued by MSA which will be helpful in understanding the scope of the CIC. Ship Managers should prepare their vessels for this Concentrated Inspection Campaign, by assessing the below list of items.

A. Steering gear

Inspection Contents

1. The main steering gear;

2. The auxiliary steering gear;

3. The remote steering gear control systems;

4. Emergency power supply;

5. The rudder angle indicator’ reading is in compliance with that of the actual position of the rudder;

6. The remote steering gear control system power failure alarm;

7. The remote steering gear power unit failure, phase loss and overload alarm;

8. The full movement of the rudder according to the required capabilities of the steering gear;

9. The operation of the means of communication between the navigation bridge and steering gear compartment (ship more than 40 meter in length);

10. The changeover between main and auxiliary steering gears.

Typical Deficiencies

1. Steering gear found out of order;

2. Mechanical parts of the steering gear found damaged;

3. The seal of rudder stock found leaking;

4. Communication device not provided between bridge and steering gear room;

5. Steering gear control system found out of work;

6. The low-level audible and visual alarm of steering gear hydraulic fluid reservoir found failed;

7. Oil-level gauge not found in steering gear hydraulic fluid storage tank;

8. Short circuit protection and an overload alarm for electrical circuits and motors of steering gear not provided in bridge or alarm found failed;

9. Power failure alarm of steering gear found out of work;

10. Phase loss alarm of steering gear out of work;

11. The rudder not capable of being put to a degree within a period of time in accordance with SOLAS;

12. Handrails and gratings or other nonslip surfaces not provided in steering gear compartments;

13. Loss of steering capability due to grounding;

14. Key crew members not familiar with the emergency steering procedures;

15. Key crew members not familiar with phase loss alarm test.

B. Main engine and auxiliary machinery

Inspection Contents

1. Main engine fuel oil supply systems (including pump, piping systems and separator);

2. Main engine lubricating oil systems including pump, piping systems and separator;

3. Main engine and auxiliary machinery jacket-water circulating pumps including piping systems, cooler and heater;

4. Main engine starting air system including compressor, air tank and starting air piping systems;

5. Main engine water cooling system including pump, cooler and piping systems.

Typical Deficiencies

1. The connection of outlet of high pressure pump and the high pressure fuel pipe found leaking;

2. Main engine or generator not fitted with alarm for leakage from jacketed piping system or alarm found out of work;

3. External high-pressure fuel delivery lines between the high-pressure fuel pumps and fuel injectors not protected with a jacketed piping system;

4. Main engine not fitted with low lubricating oil pressure alarm or the alarm found out of order;

5. lubricating oil failure alarm found out of work;

6. Pressure of water cooling system insufficient due to water cooling pump damaged;

7. Water temperature increases due to failure of thermostatic valve of main engine cooling system or dirty or blockage of cooler;

8. Main engine cooling system high temperature alarm found out of order;

9. Main engine starting air tank low pressure alarm found out of work;

10. In multi-engine installations which are supplied from the same fuel source, means of isolating the fuel supply and spill piping to individual engines not provided (3 types of isolation, isolating valve shall be installed not less than 5 meters away from any engine; the operational place of isolating valve shall be jacketed; remote operational arrangements shall be provided);

11. Air compressor found out of work due to cooler leaking as result of air in cooling water;

12. Main engine starting air pressure found insufficient due to one air compressor out of work or not in good condition;

13. Seawater pipe rusted and damaged, blockage of sea chest filter;

14. Main engine fresh water pump shaft seal found serious leaking;

15. Temperature control valve of main engine fresh water cooling piping found out of order;

16. Main engine fresh water cooling jacket found ruptured, fresh water temperature sensor found out of work, fresh water cooler found dirty etc.;

17. High temperature due to insufficient lubricating oil in shaft intermediate bearing;

18. Emergency shutoff arrangements near the main engine found out of work;

19. Main engine emergency shutoff arrangements installed in the bridge found out of order;

20. Alarm for low lubricating oil pressure of main engine gear transmission found out of work;

21. Alarm for high lubricating oil temperature of main engine gear transmission found out of work ( output greater than 1,470 kW);

22. Key crew members not familiar with test of main engine high pressure pipe leaking alarm;

23. Key crew members not familiar with procedure for main engine emergency operation.

C. Emergency generator

Inspection Contents

1. Starting of the generating sets;

2. Energy storing devices for starting of the generating sets;

3. Maintenance of emergency source of electrical power;

4. Testing of automatic starting arrangements, oil level and the condition of the starting arrangements for emergency generating sets.

Typical Deficiencies

1. Emergency generator failed to start;

2. Emergency generator revolution counter/lubricating oil pressure gauge found out of work;

3. Emergency generator starting energy including accumulator voltage and air pressure insufficient;

4. The electrical powers of the emergency air compressor not provided by the emergency switchboard;

5. Test of emergency generator failed;

6. Emergency generator low lubricating oil alarm found out of work;

7. Emergency generator governor found out of order;

8. Emergency generator fails to maintain stable voltage and frequency;

9. Emergency generator failed to start automatically upon failure of the electrical supply from the main source of electrical power and shall be automatically connected to and restore power to the emergency switchboard within 45 s (this applies when no accumulator battery is provided);

10. Key crew members not familiar with procedure for emergency generator operation.

These listed items are not exhaustive and may be varied to take account of the circumstances of the particular ship or its operations. Experience suggests that when an incident in relation to propulsion and auxiliary machinery failure occurs, the ship will be subject to both investigation and PSC/FSC inspection and it is highly likely that detention is inevitable. Normally, the failure of machinery and proper operation alone at the incident time will only give rise to a request to rectify the deficiency before departure (inspection action code “17”) but a combination of deficiencies of a less serious nature may result in the detention of the ship.

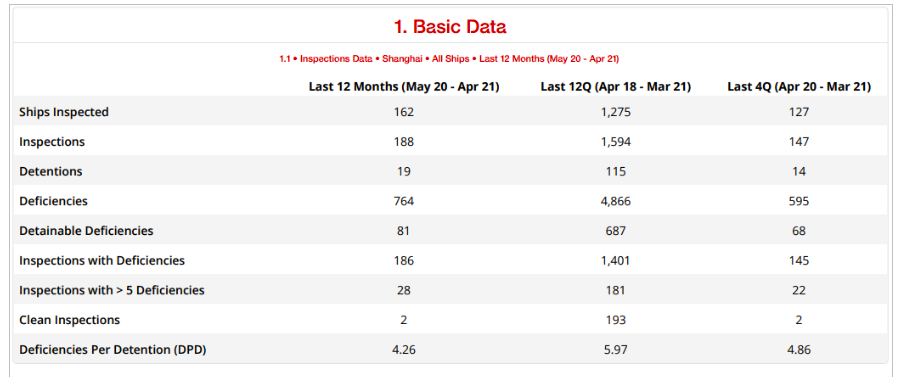

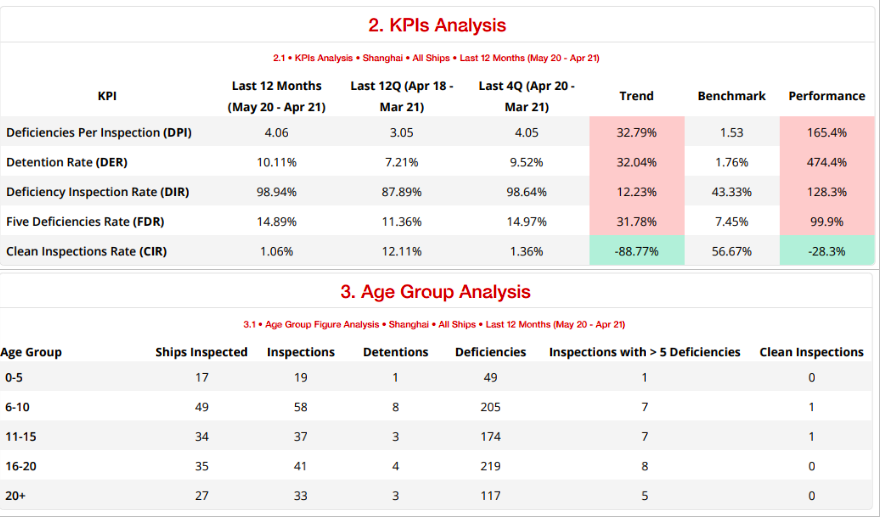

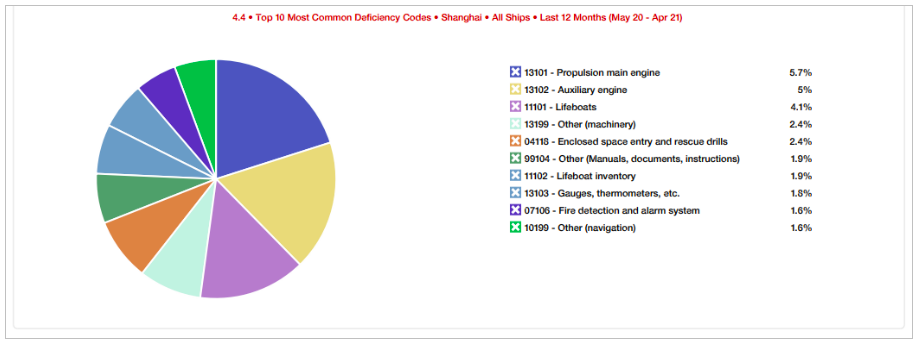

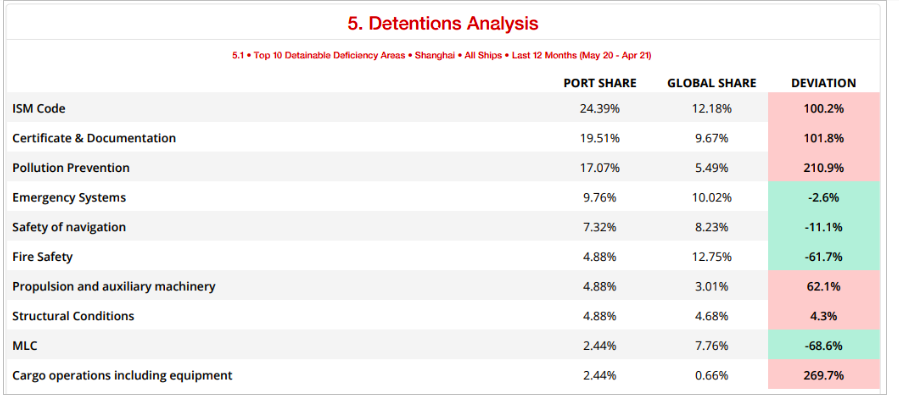

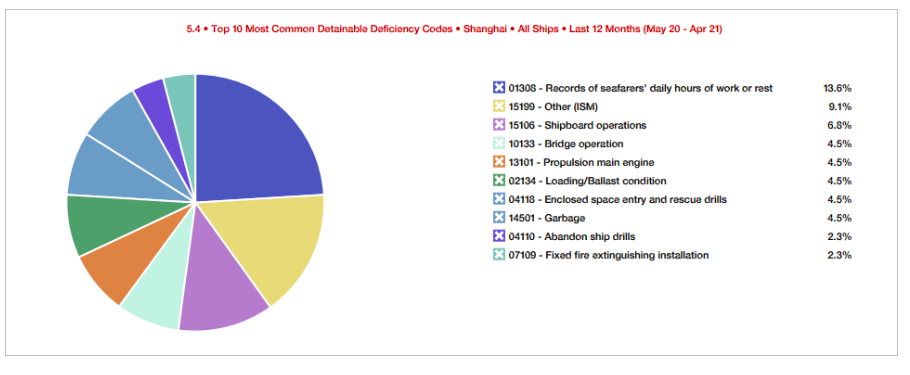

RISK4SEA Records for Shanghai, China