Port State Control (PSC) aims to verify that the condition of the ship and its equipment comply with the requirements of international regulations and that the ship is manned and operated in favor of enhanced maritime safety, security and pollution prevention.

ΙΜΟ says that PSC inspections are intended to be a “second line of defence” against substandard shipping, and experience has shown that they can be extremely effective. Although in general, ships involved in word trading are to be inspected under specific rules and requirements to any port of their trade routes, the reality is different since not all ships calling in a port are inspected. Due to resources and time pressure, Costal States have issued rules to categorize the ships in order to prioritize the resources (human/material) to target the ships with “lower performance”. So under specific calculations (involving Ship’s PSC history, Manager’s performance, Flag performance, Class performance, incidents etc) the ships are categorized as High/Standard/Low risk (or Priority I,II, non priority inn USCG area of responsibility).

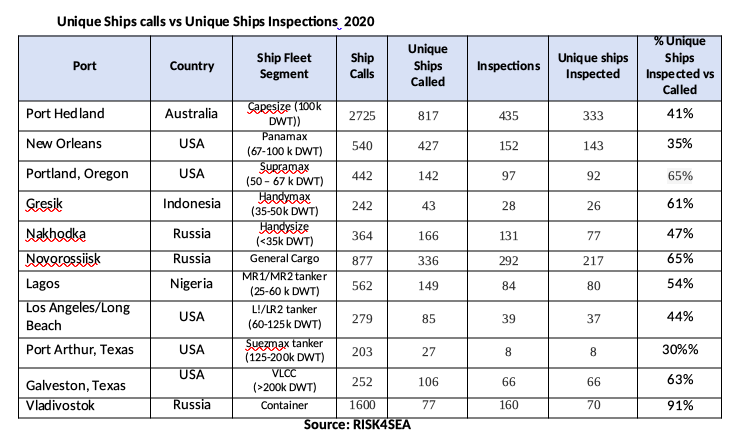

Taking into consideration the daily traffic in some certain ports, it is very difficult to target all incoming ships. The figures of last 12 months (see table below) are representative for the percentage of inspections vs Port calls (excluding inland/local trade and small ships<5000 DWT). However, it is worth mentioning that the last 12 months were quite challenging for PSC inspections and a decrease of total inspections was noticed for all ships due to the pandemic that paused trade in several parts of the world.

Ports with massive calls in key areas of the world have low percentage of inspections. That means that the priorities are kept and if the ship is low risk or non priority probably will not be inspected. For ports with lower number of calls, the PSC inspections surly extent beyond High risk ships. That means that the ship, even if it has good performance and Manager has excellent historical PSC records, it is possible to be under inspection (eg in Novorossiysk, the percentage of Bulk carriers inspected approached 100%, of the Bulk Carriers called).

As such, prior calling to a port, Managers should prepare their ships by taking into consideration the current status of ship and crew, the historical background of the ship and the Company, but mostly the common practice of the PSC authorities in this specific port. In the tight time schedule of world trading, delays imposed by PSC authorities, due detentions or repairs may disrupt the schedule of the Company and lead to upwelling claims and expenses which should be avoided. In addition, HSQE and Security departments should provide to managed vessels information of the latest PSC trends and records of the specific ports as there are significant differences to the approach in different states and ports.

Do you know the basic KPIs for PSC analysis?

Keep in mind the following abbreviations…

#1

DPI: Deficiency per Inspection (Value, Number)

Definition : Average number of deficiencies per inspection.

Performance : The smaller the figure indicates better performance

#2

DER: Detention Rate (%)

Definition : Percentage of detentions per 100 inspections.

Performance : The smaller the figure indicates better performance

#3

DIR: Deficiency Inspection Rate (%)

Definition : Percentage of inspections ending with deficiencies per 100 inspections.

Performance : The smaller the figure the better the performance

#4

CIR: Clean Inspection Rate (%)

Definition : Percentage of inspections ending with NO deficiencies per 100 inspections.

Performance : The larger the figure indicates better performance

#5

FDR: Five Deficiencies Rate (%)

Definition : Percentage of inspections with 5 or more deficiencies per 100 inspections

Performance : The smaller the figure indicates better performance

#6

DPD: Deficiencies Per Detention (Value, Number)

Definition : Average number of deficiencies per inspection that ended with a detention.

Performance : The smaller the figure indicates a stricter, more challenging inspection