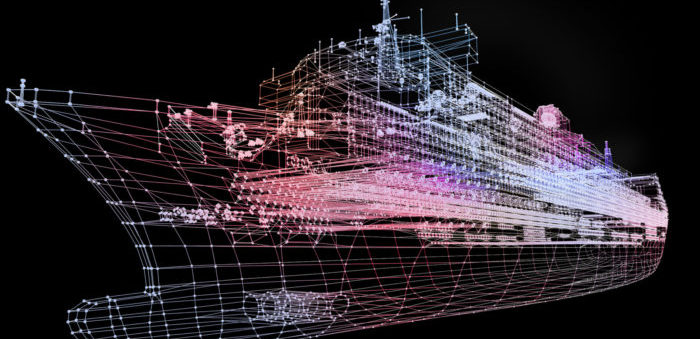

As digitalization is penetrating in the shipping industry more and more, operators can benefit from its use. One aspect of this is the digital twin concept. This provides a virtual model of a physical ship, producing valuable insights from data.

A digital twin is a digital presentation of a vessel with associated processes and systems, based on continuous data collection. And these processes or systems are presented digitally. Rather than arranging for a physical test cycle, the processes can be followed easily and quickly.

[smlsubform prepend=”GET THE SAFETY4SEA IN YOUR INBOX!” showname=false emailtxt=”” emailholder=”Enter your email address” showsubmit=true submittxt=”Submit” jsthanks=false thankyou=”Thank you for subscribing to our mailing list”]

However, as Antti Solonen from Eniram notes, the quality of data define the success of a digital twin. Namely, the use of wrong equipment, sensors and other settings can affect negatively the quality of data.

In order to solve this, data are extracted from an actual vessel, mimicking its desired characteristics. This can ensure the better quality of data by tailoring it for the specific ship.

What is very important is the fact that a digital twin can simulate how the ship will perform without needing to test it in the real world. This concept can also allow access to every bit of information on a ship, from engine performance to hull integrity, available at a glance throughout the full lifetime of the vessel.

At a glance, some areas for potential improvements that can be calculated by a digital twin are:

- Optimal operation of machinery systems.

- Optimal retrofit of batteries, more efficient thrusters, bulb etc.

- Performing hull or propeller cleaning.

- Verify ship performance on a detailed level. Visualise the effect of design choices and changes.

- Benchmarking performance towards other vessels in the fleet.

The concept is currently taking off. In fact, the Danish Maritime Authority has focused on ‘Digital Twin’ concept for shipping. As Mogens Schrøder Bech, Senior Consultant on R&D at the Danish Maritime Authority, said:

The potential of the digital twin is huge because it is possible to make a number of decisions on optimisation digitally rather than by means of physical tests. And this potential will increase along with the development of digital tools.

In addition, there is the Open Simulation Platform (OSP) initiative. The project explores the abilities of “digital twins”, with its partners creating a platform, open to other parties, to exchange information and store simulated ship, systems and equipment.

MPA Singapore also jumped on the digital twin train. MPA signed an MoU with Keppel Offshore & Marine and the Technology Centre for Offshore and Marine, Singapore (TCOMS), to jointly develop autonomous vessels for a variety of operations.

Under the deal, a project will develop a Digital Twin of a tug which will simulate vessel behaviour to help optimise the vessel operations using data analytics and visualisation tools. TCOMS will provide expertise in coupled physical-numerical modelling and simulation to evolve solutions that improve on the predictability and control of the behaviour and response of the vessel.