During the 2020 GREEN4SEA Athens Forum, Dr. Efi Tsolaki, Chief Scientific Officer, ERMA FIRST S.A. highlighted that invasive aquatic species are a major threat to the marine ecosystems, and shipping has been identified as a vital pathway for introducing species to new environments.

There are many reasons why a ballast water treatment system is necessary onboard a vessel. First of all, is for environmental protection and regulatory compliance. Invasive aquatic species present a major threat to the marine ecosystems, and shipping has been identified as a major pathway for introducing species to new environments. Thus, the BWM Convention came into force on Sept. 2017 (EIF date). Since then and till 2024 all vessels with 400 gross tonnage and above should manage their ballast water and sediment with a D2 Performance Standard.

Other reasons are:

To have the ticket to Trade

After the EIF of the convention every vessel subject to, need to have an IBWMC. Such includes the ballast water treatment via a BWTS. If such is not in place, then the vessel will not be able to trade.

To be Compliant on the Discharge

Up today the installation of an approved BWTS was enough to prove compliance. But since Oct. 2018 (BWM.2/Circ.70) additional testing for proving correct installation.

Ways for compliance

Select an efficient BWTS and not just a Type Approved one

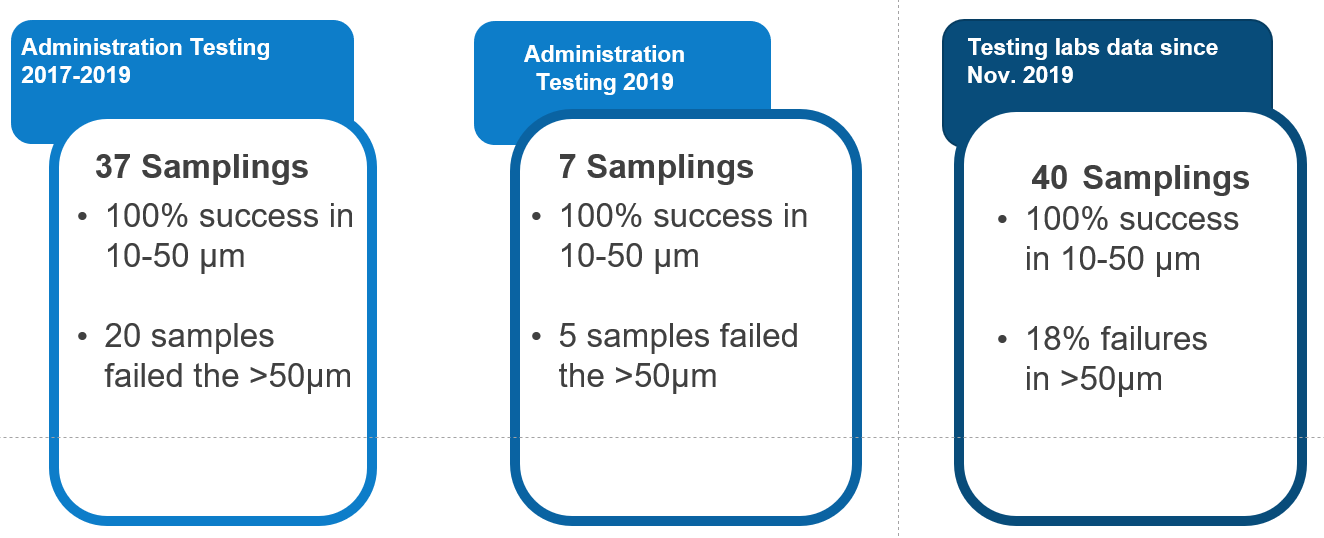

The owners should select an efficient Ballast Water Treatment System and not just a type approved one. The administrations have already contacted several compliance tests at vessels calling their ports. This is part of IMO experience Building Phase (EBP). Almost 60% of those are failing on organisms >50 μm testing.

Allow me to present some insight information that are the preliminary data for the experience building phase. We have two administrations that share data with the IMO and we are talking about testing regimes from 2017 to 2019.

So this is a problem, what we need to do is to understand what is the reason behind this. Why we have the failure of more than 50 microns.

The following failing reasons were identified:

- Lack of adequate filtration

- Damaged filter screens

- Use of different size screen than that used during the Type Approval Testing

- Contamination due to valve leakages

- Contaminated Ballast Water Tanks

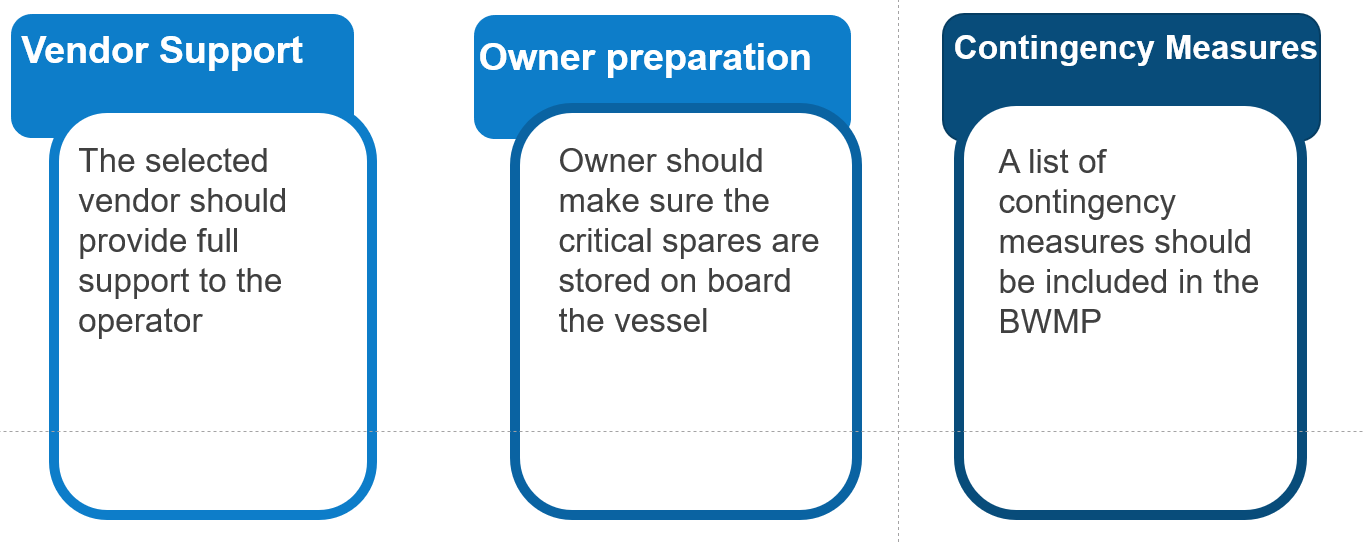

Following the second way to compliance with the Convention is:

The use the BWTS

Once it is installed, there are a lot of cases where shipowners are having their systems just in idle, so they don’t operate them. The system should be operable on every operation.

In order to use the Ballast Water Treatment System, shipowners have to:

Last, as it was mentioned by previous speakers, the crew training is a very important aspect.

Crew training

The crew should be familiar with the Convention requirements and the use of Ballast Water Treatment System that is installed onboard. In fact, the crew should be familiar with the documentations, the records, the vessel that should keep and report to every port and the flag.

So, the crew should be well trained on the operations. It was identified that training during commissioning has been proved not efficient.

Land based training at a training center and Computer Based Training are two efficient ways to keep the crew updated and well educated.

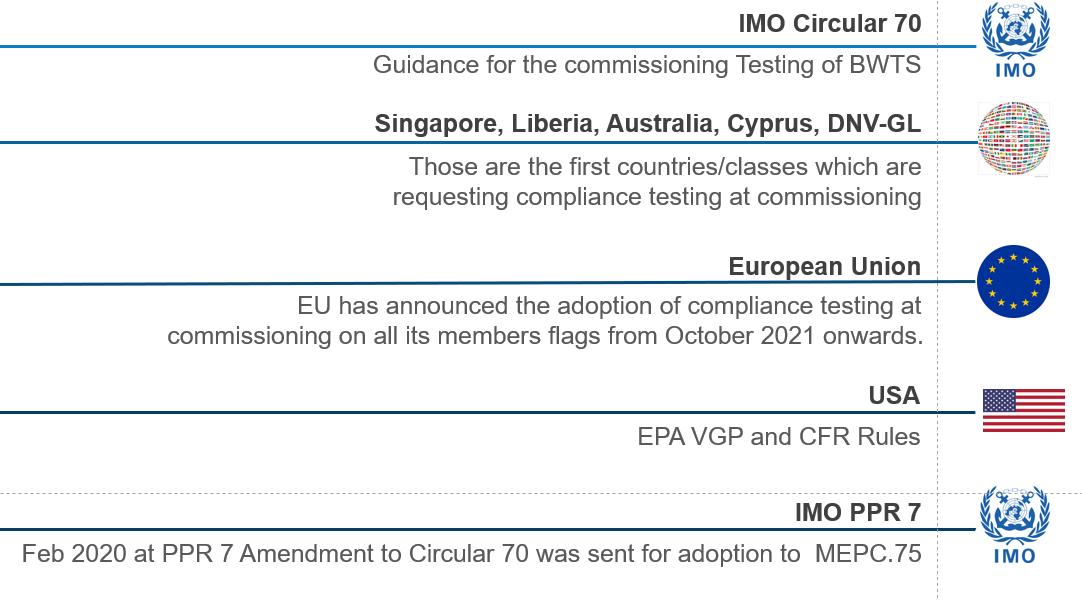

Going back to what is the way to compliance. The following slide is the legislation trend that is around:

Circular 70 was introduced by IMO back in 2018 and is the guidance for the commissioning testing.

This summer, there were some countries that shared circulars or notice guidance for the commissioning testing. Such as Singapore, it is not Liberia yet but is Panama, Australia, Cyprus and from classification societies DNV GL.

These are the first countries and classes that requesting compliant testing during the commissioning.

Also, the European Union has announced the adoption of the compliance testing at the commissioning on all the members from October 2021.

Onwards we have the USA. We are talking about a different perspective, protocols and sampling. So, there we have two different bodies for regulating this. We have the EPA VGP and what it is mandated in the CFR rules.

Finally, we have a very recent approach on the guidance of the commissioning, this is the circular 70, which was discussed two weeks ago in the IMO PPR 7. So, we have now a new draft on the circular that will be moved forward maybe to MEPC 75 that will take place in the end of March.

I would like to just investigate what is in circular 70, what are the parameters that we measure for compliance. So we can put them in three different categories, which are:

Organisms >50 μm

Those are mainly zooplankton which is hard to render with the use of Active Substance (Chlorine, Chlorine Dioxide, Ozone etc) or UV radiation. Mechanical means such as filters are required unless an in-tank BWTS is used.Organisms 10-50 μm

Those are mainly phytoplankton, easy to render with the use of Active Substance (Chlorine, Chlorine Dioxide, Ozone etc) or UV radiation. Many portable devices with high accuracy are already available to measuring those.

Indicators

Those are the pathogens such as cholerae, E-Coli and Enterococcus. Those are extremely easy to render with the use of low Active Substance or UV radiation dosage. Those mainly concern the human health. This is the reason why only those are included in the EPA’s VGP analysis.

So, what is the way forward?

#1 The compliance testing

This has arrived to stay, so we should all be prepared for making the Ballast Water Management Systems and this installation in success.

#2 The Indicative Analysis Tools

The frequent use of the already available portable compliance tools will provide a good performance evidence prior any official testing.

#3 IBWMC Renewal

Most probably after 2022, when the EBP finishes, compliance testing should be part of the annual IBWMC renewal.

#4 Ask for Compliance Testing

Compliance testing at commissioning eventually will become industry’s standard.

With these we can follow a roadmap for a successful implementation of the Convention and the effective experience building phase.

Above article is an edited version of Dr. Efi Tsolaki’s presentation during the 2020 GREEN4SEA Athens Forum.

You may view her presentation here below

The views expressed in this article are solely those of the author and do not necessarily represent those of SAFETY4SEA and are for information sharing and discussion purposes only.

Efi Tsolaki, Chief Scientific Officer, ERMA FIRST S.A.

Efi started her journey in Environmental Engineering in 1998. Wastewater treatment and management “enslave” her interests. Through her PhD back in 2005 in Technical University Of Crete, Greece, she was introduced to the problem of Invasive Species and ballast water. She is the first academic in Greece with specialization in Ballast Water and joined ERMA FIRST in early 2010. From the beginning of her career in the marine industry she was focused on Research and Development, certification of the systems and environmental policies. She acts as the Chief Scientific Officer of the company with main responsibility of the certification process, applying all relevant international regulations, business development worldwide and environmental compliance, safety and marine preservation. Her latest project is the USCG Type Approval Certificate and the IMO new G8. She is the Vice President of BEMA (Ballast water Manufactures Association), Part of Greek Delegation on IMO Committees MEPC and PPR as Technical Advisor and participates in Ballast water Expert on IMAREST.

Efi started her journey in Environmental Engineering in 1998. Wastewater treatment and management “enslave” her interests. Through her PhD back in 2005 in Technical University Of Crete, Greece, she was introduced to the problem of Invasive Species and ballast water. She is the first academic in Greece with specialization in Ballast Water and joined ERMA FIRST in early 2010. From the beginning of her career in the marine industry she was focused on Research and Development, certification of the systems and environmental policies. She acts as the Chief Scientific Officer of the company with main responsibility of the certification process, applying all relevant international regulations, business development worldwide and environmental compliance, safety and marine preservation. Her latest project is the USCG Type Approval Certificate and the IMO new G8. She is the Vice President of BEMA (Ballast water Manufactures Association), Part of Greek Delegation on IMO Committees MEPC and PPR as Technical Advisor and participates in Ballast water Expert on IMAREST.