The North P&I Club launched three different checklists concerning the “care” of nickel ore, grain and coal, providing details to interested parties on how to deal with this kind of cargo.

#1 Cargo Care Checklist: Nickel Ore

Prior to loading documentation received from shipper is needed.

Also, the Club advises that visual inspection should be conducted before it is loaded, in cases that it is allowed and safe.

You should look for:

- excessive moisture prior to loading

- Perform a can test before and during loading

In addition, the Master of the vessel is resp

- Daily report

- LOPs as required

To learn more, click herebelow

#2 Cargo Care Checklist: Grain

Hold preparation is a major step, unless otherwise stated in shipper’s or charterers voyage instructions.

The National Cargo Bureau’s definition of grain clean is as follows:

Compartments are to be completely clean, dry, odour-free, and gas-free. All loose scale is to be removed.

Some loose scale / rust is allowable however the following would not be acceptable as Grain Clean:

- Scale or loose paint breaks when struck with fist or light pressure from knife.

- A single area of loose rust or paint is 2.5 m2

- The total quantity area of loose rust or paint is more than 9m2

Before the loading operations:

- Port tidal ranges and times known and posted

- Arrival draughts and tank conditions noted

- Cargo details including quantity provided

- Shippers instructions on cargo care received

- Fumigation requirements provided

- Cargo loading sequence discussed and agreed

- Average moisture content of cargo is provided in certificate of quality

During loading, deck officers should monitor operations and acquire photographic evidence throughout the operation.

The weather should be monitored in case of rain and the cargo should be in good condition, which can be understood by its color or the smell.

On discharge, the ship may consider of having a local surveyor, in particular for claims hotspots such as China.

Also, the Club recommends the steps below:

- Camera ready with date and time set for evidence taking (continuous photographic record to be taken)

- Arrival times noted including notice of readiness tendered

- Vessel condition known including draughts

- No signs of self-heating

- No signs of mould growth

- No colour changes to the cargo

- No unusual odours

- No signs of infestation

- Cargo temperature recorded on discharge

- Monitor any tally operations

- Draught survey results to be confirmed as accurate and agreed by all parties

- Received copies of any 3rd party surveyor reports

- Ensure on completion an empty hold certificate is issued

- Ensure an out turn report / certificate is agreed

To explore more on grain, click herebelow

#3 Cargo Care Checklist: Coal

The vessel should be equipped with calibrated and certified gas monitoring equipment fitted with a catalytic sensor, which will measure methane, oxygen and carbon monoxide in an oxygen-depleted atmosphere.

Testing equipment to monitor the pH of bilge water. Temperature measuring equipment capable of monitoring temperature of between 0°c and 100°c

It is important to be aware of the cargo temperature, which should on loading should be confirmed as less than 55 degrees Celsius.

If cargo temperature greater than 55 degrees, reject cargo and follow company procedures with letter of protest and request an expert.

During loading, you should be alerted about signs of liquefaction or sign of foreign matte

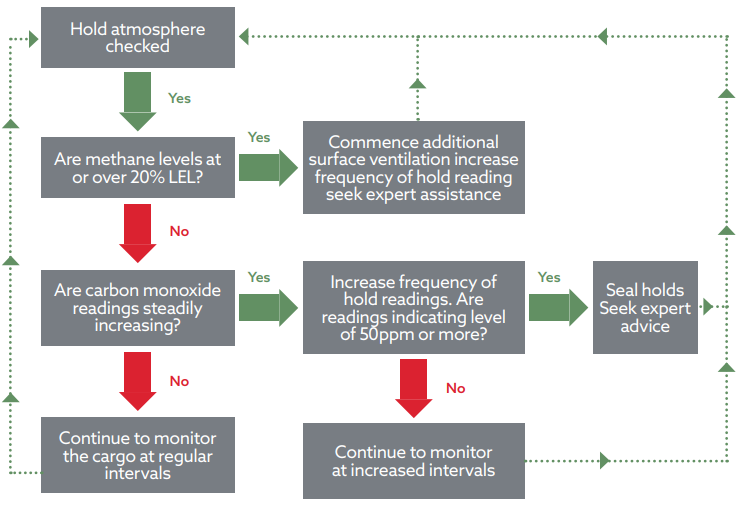

On passage, the vessel should monitor the hold atmosphere for the concentrations of methane, oxygen and carbon monoxide at regular intervals and the readings recorded. Hold bilge water should be tested for its pH level, if acidic, increase the frequency in which bilges are emptied.

Ensure that personnel do not enter any cargo hold or adjacent enclosed space until the space has been ventilated and the atmosphere tested and confirmed as safe for entry

In discharge confirm the safe hold atmosphere before letting personnel enter and be sure that methane levels are acceptable before hatches are opened.

Click herebelow to learn more