The German Federal Bureau of Maritime Casualty Investigation (BSU) published an incident report in which a worker experienced electric sock while plugging a container into a socket in during August of 2020 in Hamburg.

The incident

An incident involving personnel occurred on board the fully-containerised vessel MONTREAL EXPRESS at 20063 on 29 August 2020. At this point, the ship was at its berth in the port of Hamburg for cargo-handling operations.

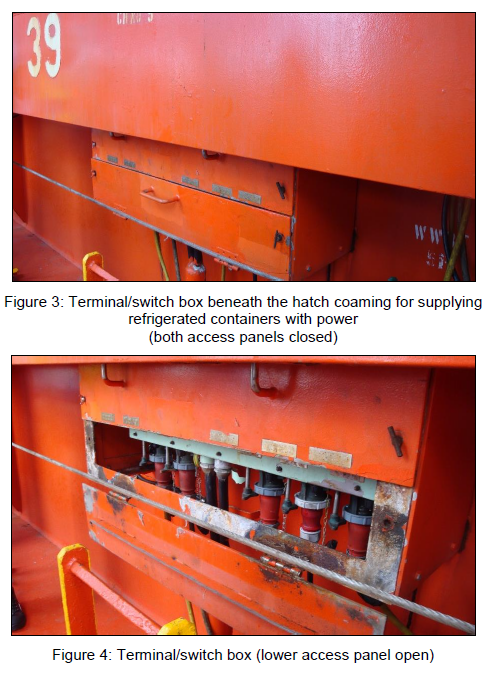

A dock worker had intended to connect a refrigerated container stowed on deck in the area of bay 38/39 to the ship’s power supply system. To this end, he went to the nearest terminal/switch box with the plug of the power cable, which was fitted to the container in the usual manner. This was located on the port side of the ship below the hatch coaming in the area of bay 39.

There was a sudden flash of light when the dock worker was inserting the cable’s plug into the socket. He felt a mild electric shock but was able to leave the scene unassisted and report the occurrence to his supervisor. The latter immediately called an emergency physician and notified the ship’s command and Waterway Police (WSP) Hamburg.

The crew of an ambulance was at the scene just a short time later and examined the dock worker, who exhibited no injuries but was in a state of shock. He was taken to hospital for further observation as a precaution but was able to leave it soon after. Apart from him temporarily being in a mild state of shock, the incident did not give rise to any adverse health effects.

Analysis

An analysis of all available information made it possible to clarify, beyond doubt, the cause of the electric shock suffered by the dock worker while connecting the refrigerated container to the on-board electricity supply system of the MONTREAL EXPRESS. The expert commissioned by the BSU’s assessment of the relevant power supply equipment was particularly helpful in this respect.

Following the assessment of all sources of information, it is clear that moisture inside the inadequately sealed terminal/switch box at bay 38/39 (port side) caused a so-called ‘creepage distance formation’. Since the PE conductor was interrupted or at least its functionality severely impaired by corrosion and/or a loose contact at the same time, the residual current caused by the creepage distance formation was not (only) discharged directly via this conductor toward the hull of the ship. Instead, at least part of the residual current flowed through the body of the dock worker when he touched the switch box housing, causing him to suffer an electric shock.

The assessment of the terminal/switch boxes on board the MONTREAL EXPRESS revealed that the design of the protective earthing (use of a female tab adaptor at the end of the earth lead and a male tab adaptor mounted on the removable housing cover, as well as connection of the main earthing of the terminal/control box to the hatch coaming by means of a screw connection that was completely exposed to external influences and not well secured) was highly susceptible to contact impairments and contact losses.

One factor facilitating the course of events leading up to and during the accident was that although the ship was crewed by a ship’s electrician, the maintenance condition of the randomly inspected terminal/switch boxes and associated supply cabinets was inadequate. Internationally binding rules state that the granting of a certificate of proficiency as a ship’s electrician requires sound expertise in the use, monitoring, maintenance and repair of electrical equipment, machinery and systems on board, as well as knowledge of the relevant aspects of occupational health and safety and accident prevention. Nevertheless, maintenance works carried out in individual boxes in the past evidently involved methods of repair that did not comply with the generally recognised rules of technology.

It is also clear that the potential risk posed by the terminal/switch box was not an isolated case (in relation to the MONTREAL EXPRESS). This is evident from the fact that prior to the publication of this investigation report, WSP Hamburg, which had become aware of this problem, subsequently notified the BSU of five further incidents in which comparable health hazards to dock workers during the connection of refrigerated containers had occurred on five different container ships of other shipping companies in the port of Hamburg alone. Fortunately, what all cases had in common was the fact that the people affected were not seriously injured.

The accumulate on of such incidents gives rise to concerns that STCW Contracting States do not always pay sufficient attention to ensuring that the required specialist knowledge (see above) of a ship’s electrician actually exists in full when they issue certificates of proficiency for this responsible role on board.

Another aspect contributing to the risk of accidents arising from poorly maintained terminal/switch boxes for refrigerated containers is that this area of technology on board is evidently not a particular focus of inspectors during class surveys and port State controls. Although both the requirements of the classification societies and the international rules and regulations for port State controls provide for random inspections of the boxes in question, which are also subject to stringent design regulations, the terminal/switch boxes on board the MONTREAL EXPRESS inspected by the BSU’s expert exhibited various defects that had evidently existed for some time. Accordingly, these boxes had not been inspected for quite some time.

It is reasonable to assume that dangerous incidents relating to the connection of refrigerated containers frequently occur in ports around the world but that they are not reported due to their benign outcome and therefore not investigated. This in turn is probably one of the main reasons why (random) inspections of the relevant equipment on board do not appear to be sufficiently prioritised given the serious dangers defective electrical systems may pose.

Both the classification society of the MONTREAL EXPRESS and the Ship Safety Division responsible for port State control inspections in Germany’s ports have made clear in their statements that the existing survey and inspection regime provides sufficient opportunities for identifying inadequately maintained terminal/switch boxes for refrigerated containers. Accordingly, the BSU sees no need to address safety recommendations to the above bodies in this regard.

However, it must be questioned whether the current control frequency actually delivers an effective basis for remaining sufficiently aware of the existing potential risk, which is evidently not restricted to extremely isolated cases. Shipping companies, classification societies and bodies responsible for port State controls should therefore be made more aware of the dangers described by means of this summary investigation report and the timely publication of generally applicable lessons learned.

Safety recommendations to the shipping company of the MONTREAL EXPRESS are not necessary. With the measures implemented, which can be regarded as exemplary, it has responded appropriately to the potential hazards identified.