The Australian Maritime Safety Authority issued its maritime safety awareness issue 10 focusing on safety access onboard a vessel, as unsafe gangways or accommodation ladders needs the proper safety measures to avoid any accident.

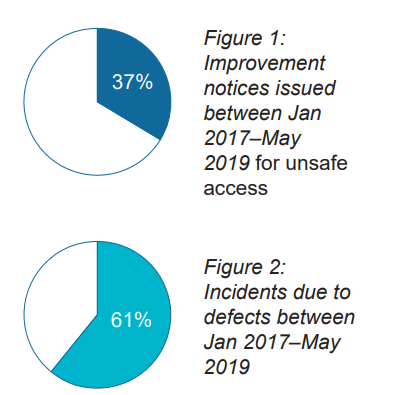

According to AMSA’s data, from January 2017 to May 2019 there were 76 improvements out of which 28 involved unsafe access. At the same time, 62 safe access accidents and incidents were reported with 38 due to defects. These statistics indicate safe access is a significant safety issue. Defects in the equipment, particularly gangways and accommodation ladders being the major cause.

Safety onboard a vessel is affected from a variety of factors, such as poor equipment design and maintenance, time and resource pressures and inadequate risk assessments.

The requirements for safely rigging vessel access equipment are set out in MSC. 1/ Circ.1331 and SOLAS regulation II-1/3-93. In Australia, these standards are codified in Marine Order 12 section 24 and include:

- Gangways should not be used at an angle of inclination greater than 30 degrees from the horizontal.

- Ship accommodation ladders should not be used at angles greater than 55 degrees from the horizontal, unless designed and constructed for use at angles greater than these, and marked as such.

- Provide adequate lighting, lifebuoys and a mounted safety net sufficient to prevent falls.

- Accommodation ladders and gangways shall be positioned well forward of propeller and avoid the lower part of the ladder and gangway overhanging off steep ship sides.

AMSA further explains why the picture below poses risks for the seafarers.

The picture below presents a poorly selected access method and an unsafe rigging accommodation ladder. The ladder is rigged at more than 55 degrees from the horizontal. It is suspended over the sea. There are more people on the ladder than the load rating of the gangway. There is a high risk of a person losing their footing and causing others to fall with them.

Poor equipment design may also affect safe access. Crew are more likely to develop shortcuts or workarounds if the equipment they are using is incompatible with the realities of the task at hand.

In addition, maintenance is a crucial part when ensuring a vessel’s safe access; Given that 61% of safe accidents were due to defects, regular inspections and maintenance of access equipment needs to be incorporated into the vessel’s planned maintenance system, and recorded.

Maintenance includes regular inspection of welds, distortion, cracks and corrosion. AMSA suggests that additional areas to focus on are:

- moving parts should move freely and are greased appropriately;

- regularly inspecting the underside of gangways and accommodation ladders;

- careful attention given to the hoist wire, including the dates for renewal of wires used to support vessel access, as per SOLAS II-1/3-9);

- check the accommodation ladder and gangway each time after they are rigged.

In the meantime, coping with unsafe gangways or accommodation ladders needs the proper safety measures since the adjustment of gangways and accommodation ladders involve a heightened level of risk of falling from height, persons falling overboard, and entanglement.

On the right, a crewmember secures a fallen defective accommodation ladder via a pilot ladder without wearing appropriate personal protective equipment, such as a lifejacket or fall-arrest device. The cargo vessel is underway and the risk of the crew member being injured or falling in the water close to a propeller are high.

Moreover, AMSA informs that on the occasion that a vessel is next to a berth it’s up to the vessel and the port to provide a safe access. Wharf arrangements should be considered when assessing the risks. Often, it is poor wharf design that prevents the gangway from being landed and this has a significant impact on the safety of access arrangements.

Communication is an important factor to acknowledge the obstacles to safe access. Also, cooperation between pilot and ship’s crew can help to mitigate these issues by positioning the vessel alongside to clear the obstacles before the ship is made fast.